Method for purifying aminopyrimidine

A technology of aminopyrimidine and purification method, which is applied in the field of aminopyrimidine purification, and can solve the problems of low yield and quality of vitamin B1

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for purifying aminopyrimidine, the steps of which are:

[0041] a. Formylpyrimidine: sodium hydroxide: water = 1:2:4 ratio, heat up and dissolve, keep warm at 100°C for 3 hours to obtain aminopyrimidine solution;

[0042] b. Cool down to 5-10°C, the aminopyrimidine solid precipitates out, and the aminopyrimidine is filtered out;

[0043] c. Wash the aminopyrimidine solid with methanol to remove impurities, and the ratio of aminopyrimidine to methanol is 1:2;

[0044] d. Filter out aminopyrimidine, add water and heat up to 70°C to dissolve, the ratio of aminopyrimidine to water is 1:0.5;

[0045] e. The temperature is lowered to 5-10° C., the aminopyrimidine solid is precipitated, and the pure aminopyrimidine is obtained by filtering and drying.

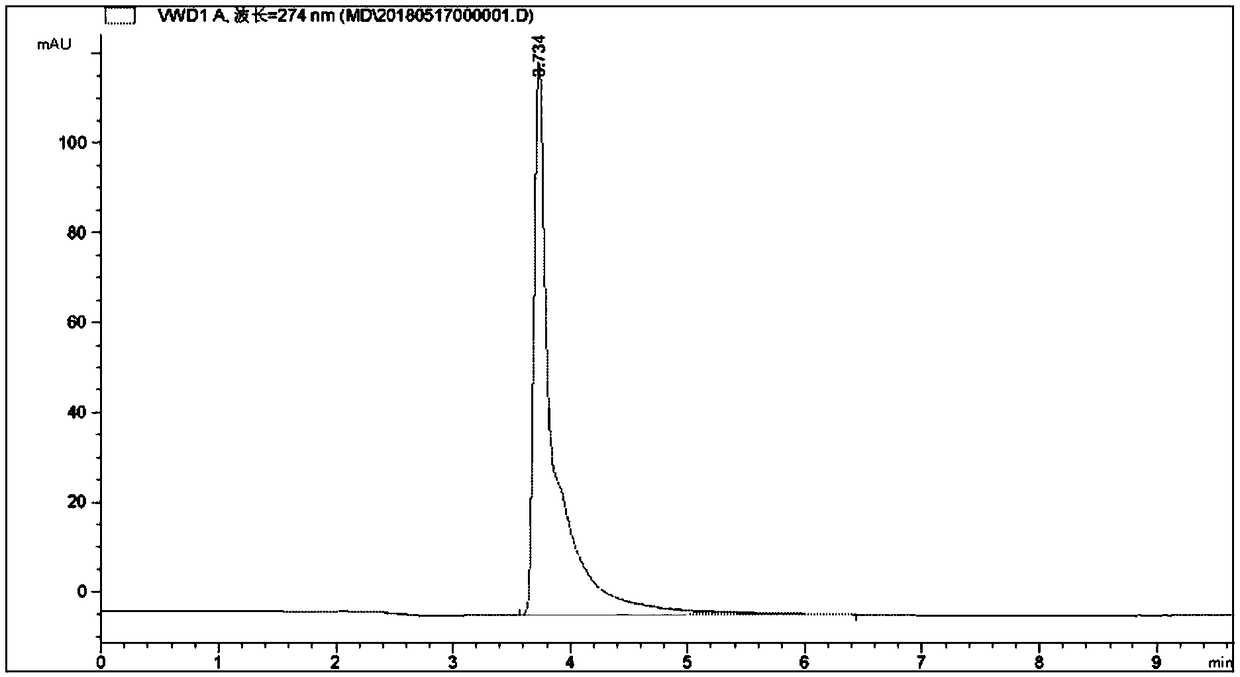

[0046] f, the aminopyrimidine pure product that obtains detects, as figure 1 shown.

[0047] figure 1 The information in it is shown in Table 1.

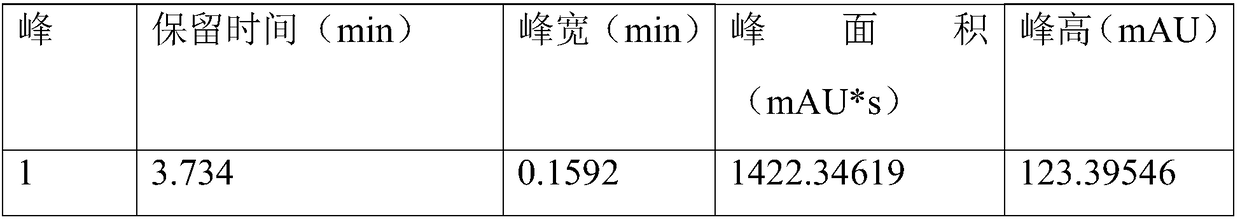

[0048] Table 1 Detection peak information

[0049]

[0050] A...

Embodiment 2

[0060] A method for purifying aminopyrimidine, the steps of which are:

[0061] a. Formylpyrimidine: sodium hydroxide: water = 1:1:3 ratio, heat up and dissolve, keep warm at 80°C for 4 hours to obtain aminopyrimidine solution;

[0062] b. Cool down to 0-5°C, the aminopyrimidine solid precipitates out, and the aminopyrimidine is filtered out;

[0063] c. Wash the aminopyrimidine solid with methanol to remove impurities, and the ratio of aminopyrimidine to methanol is 1:2;

[0064] d. Filter out aminopyrimidine, add water and heat up to 50°C to dissolve, the ratio of aminopyrimidine to water is 1:0.5;

[0065] e. The temperature is lowered to 0-5° C., the aminopyrimidine solid is precipitated, and the pure aminopyrimidine is obtained by filtering and drying.

[0066] f, the obtained pure aminopyrimidine is detected.

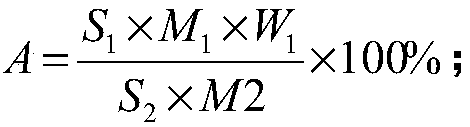

[0067] Aminopyrimidine content, i.e. aminopyrimidine purity, is calculated as follows:

[0068]

[0069] Wherein, A—aminopyrimidine content;

[0070] S 1...

Embodiment 3

[0077] A method for purifying aminopyrimidine, the steps of which are:

[0078] a. Formylpyrimidine: sodium hydroxide: water = 1:2:5 ratio, heat up and dissolve, keep warm at 120°C for 2 hours to obtain aminopyrimidine solution;

[0079] b. Cool down to 10-20°C, the aminopyrimidine solid precipitates out, and the aminopyrimidine is filtered out;

[0080] c. Wash the aminopyrimidine solid with methanol to remove impurities, and the ratio of aminopyrimidine to methanol is 1:2;

[0081] d. Filter out aminopyrimidine, add water and heat up to 80°C to dissolve, the ratio of aminopyrimidine to water is 1:0.5;

[0082] e. The temperature is lowered to 10-20° C., the aminopyrimidine solid is precipitated, and the pure aminopyrimidine is obtained by filtering and drying.

[0083] f, the obtained pure aminopyrimidine is detected.

[0084] Aminopyrimidine content, i.e. aminopyrimidine purity, is calculated as follows:

[0085]

[0086] Wherein, A—aminopyrimidine content;

[0087]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com