Method for purifying kaolin

A purification method and kaolin technology are applied in the field of purification and preparation of kaolin, can solve problems such as non-conformity, insignificant improvement of kaolin whiteness, water quality and environmental pollution, etc., and achieve whiteness improvement, simple and convenient purification method and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

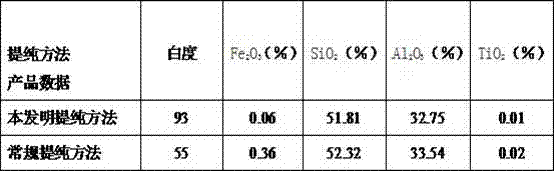

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

[0020] The kaolin raw ore is firstly selected to remove large impurity minerals, then the raw ore is coarsely crushed and finely crushed, and then passed through a 100-mesh sieve. The washed kaolin mud is input into the classification tank for classification to remove fine sand.

[0021] Put the mud into the slurry storage tank for washing, then adjust the mud concentration to 70-75 degrees Baume meter, pump it into the imported ball mill for fast ball milling, and the high-alumina ball mills in the ball mill must be proportioned according to the following gradation: large : Medium: Small = 2:5:3. After the mud is ball-milled, pass through a 400-mesh sieve, then dilute it, add an appropriate amount of special high-dispersion agent to fully disperse the pseudo-particles, separate the kaolin particles fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com