Purification device and method for epoxy compound-containing material

An epoxy compound and purification device technology, applied in the field of purification, can solve problems such as unsatisfactory wastewater treatment effects, and achieve the effects of easy operation, high removal rate, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

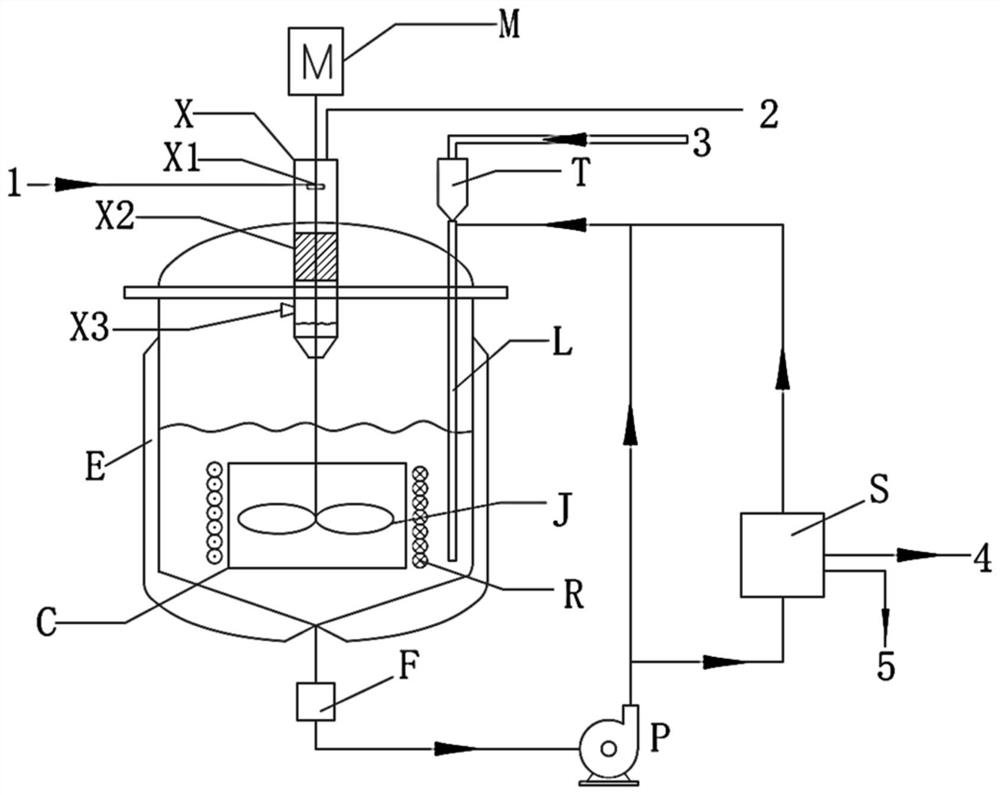

[0099] The present embodiment provides a purification device for materials containing epoxy compounds, such as figure 1 As shown, the purification device includes: a feed unit, a washing unit X, a catalytic hydrolysis unit and a separation unit;

[0100] The feeding unit includes an anti-suckback device T and a material pipe L connected in sequence;

[0101] A hydrolyzate feeding port is arranged between the anti-suckback device T and the material pipe L;

[0102] The anti-suckback device T is provided with a material feed port 3;

[0103] The lowest end of the material pipe L is located below the working liquid level of the catalytic hydrolysis unit;

[0104] The rinsing unit X includes a spray head X1, an adsorption layer X2 and a treated gas inlet X3 arranged sequentially from top to bottom;

[0105] The rinsing unit X is arranged on the upper part of the purification device;

[0106] The lowest end of the rinsing unit X is higher than the working liquid level of the ri...

Embodiment 2

[0114] The epoxy compound-containing material in this embodiment is an aqueous solution containing 12.5% (mass percentage) of propylene oxide.

[0115] This embodiment provides a method for purifying materials containing epoxy compounds, said method comprising the steps of:

[0116] (1) Feed the material containing epoxy compound and liquid into catalytic hydrolysis unit to carry out catalytic hydrolysis reaction, obtain the liquid after reaction; Wherein, described epoxy compound comprises propylene oxide; The mass percentage of epoxy compound in the described material The content is 12.5%; the material is a liquid material; the catalyst in the catalytic hydrolysis reaction is a sulfuric acid solution; the mass concentration of the catalyst is 10g / L; 1%; the pressure of the catalytic hydrolysis is 0.5MPaG; the reaction temperature of the catalytic hydrolysis is 140°C; the reaction time of the catalytic hydrolysis is 0.5h; the stirring rate of the catalytic hydrolysis is 200...

Embodiment 3

[0120] The epoxy compound-containing material in this embodiment is nitrogen containing 16% (mass percent) butylene oxide.

[0121] This embodiment provides a method for purifying materials containing epoxy compounds, said method comprising the steps of:

[0122] (1) feed the material and liquid containing epoxy compound into the catalytic hydrolysis unit to carry out the catalytic hydrolysis reaction, and obtain the liquid after the reaction; wherein, the material is butylene oxide gas material; the quality of butylene oxide in the material The percentage content is 16%, the flow rate is 50Nm 3 / h; the catalyst in the catalytic hydrolysis reaction is potassium hydroxide solution; the mass concentration of the liquid phase catalyst is 12g / L; the addition of the catalyst is 1.2% of the total liquid material quality in the purification device; The pressure of the catalytic hydrolysis is 1MPaG; the reaction temperature of the catalytic hydrolysis is 120°C; the reaction time of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com