Purification system of sulfur-containing tail gas of high-temperature furnace

A purification system and high-temperature furnace technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of excessive sulfur oxide content, cure the symptoms but not the root cause, and increase the height of the chimney, so as to reduce pollution and achieve good results. less demanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

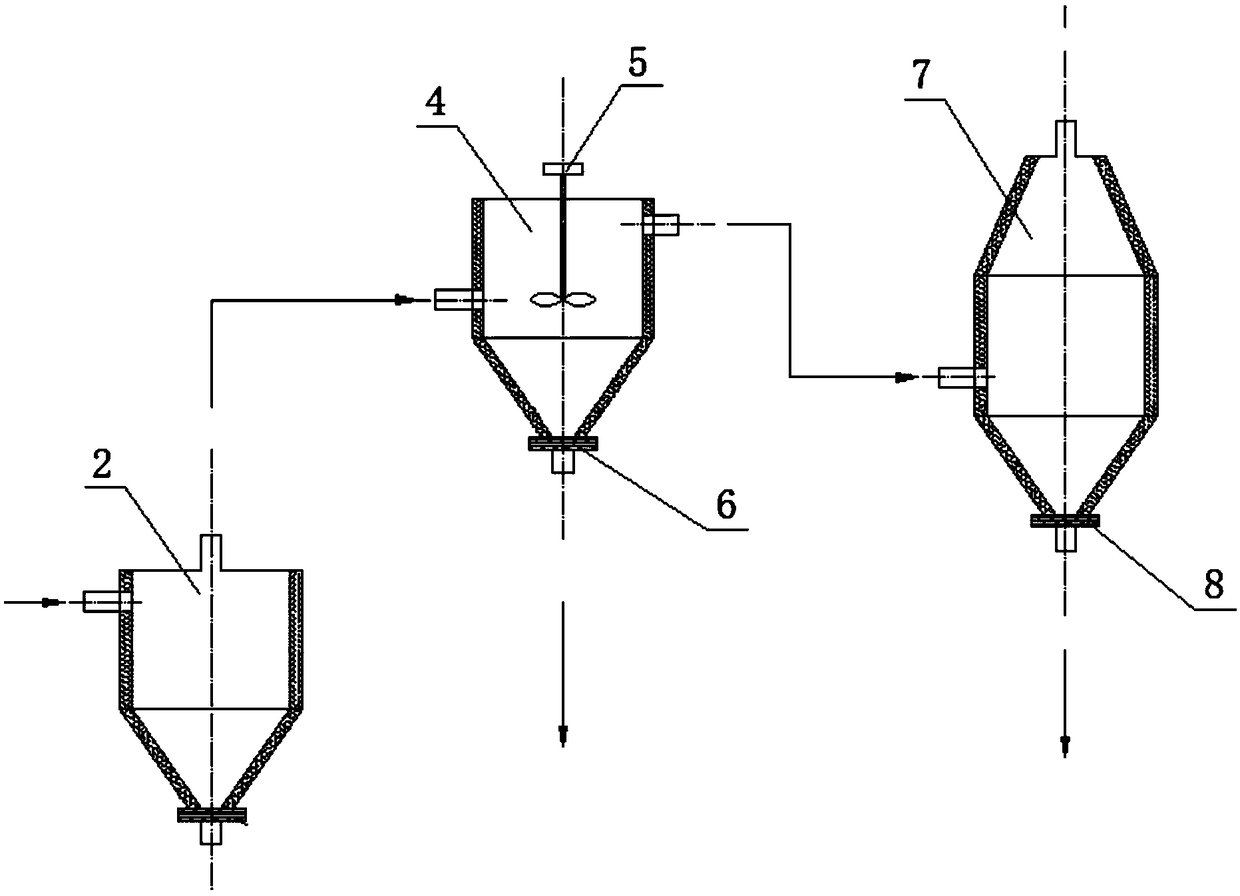

[0040] When the processing capacity of expandable graphite is 39.0kg / h, it is measured that the gas medium tower discharged from the top of the solid-gas separation system 2 contains 4.5mg / L of sulfur dioxide, and after the acid-base neutralization reaction in the calcium hydroxide reactor 4, the generated Ca(HSO 3 ) 2 The amount of sulfur dioxide in the gas is 20.1kg / h, and the content of sulfur dioxide in the gas is 2.5mg / L. After the reaction with sodium hydroxide lye in the sodium hydroxide reaction tower, the product NaHSO 3 The amount of sulfur dioxide is 22.0kg / h, and the final gas discharged by the fan has a sulfur dioxide concentration of 0.10mg / L, which is lower than the emission standard required by the National Environmental Protection Agency.

Embodiment 2

[0042] When the processing capacity of expandable graphite is 27.8kg / h, the measured gas discharged from the top of the solid-gas separation system 2 contains 3.2 mg / L of sulfur dioxide, which is produced after the acid-base neutralization reaction in the calcium hydroxide reactor 4. Product Ca(HSO 3 ) 2 The amount of sulfur dioxide in the gas is 14.3kg / h, and the content of sulfur dioxide in the gas is 1.5mg / L. After the reaction with sodium hydroxide lye in the sodium hydroxide reaction tower, the product NaHSO 3 The amount of sulfur dioxide is 13.2kg / h, and the final gas discharged by the fan has a sulfur dioxide concentration of 0.08mg / L, which is lower than the emission standard required by the National Environmental Protection Agency.

Embodiment 3

[0044] When the processing capacity of expandable graphite is 53.0kg / h, the measured gas discharged from the top of the solid-gas separation system 2 contains 6.1mg / L of sulfur dioxide, which is produced after the acid-base neutralization reaction in the calcium hydroxide reactor 4. Product Ca(HSO 3 ) 2 The amount of sulfur dioxide in the gas is 27.2kg / h, and the content of sulfur dioxide in the gas is 3.1mg / L. After the reaction with sodium hydroxide lye in the sodium hydroxide reaction tower, the product NaHSO 3 The amount of sulfur dioxide is 25.3kg / h, and finally the gas discharged by the fan has a sulfur dioxide concentration of 0.13mg / L, which is lower than the emission standard required by the National Environmental Protection Agency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com