Continuous-beam 0#-block bottom-board-web mass-concrete temperature control construction method

A large-volume concrete and construction method technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of damaging the internal structure of concrete, affecting the performance of concrete, and large heat of hydration of concrete, so as to reduce heat and improve Construction efficiency, quality assurance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

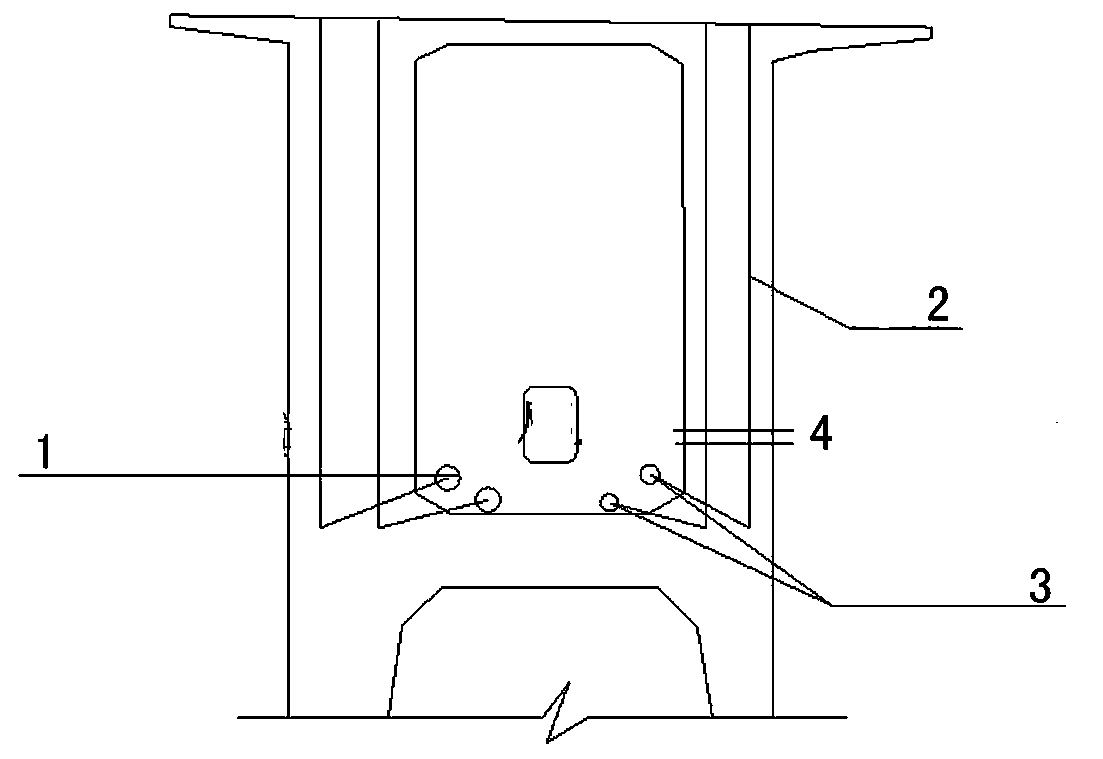

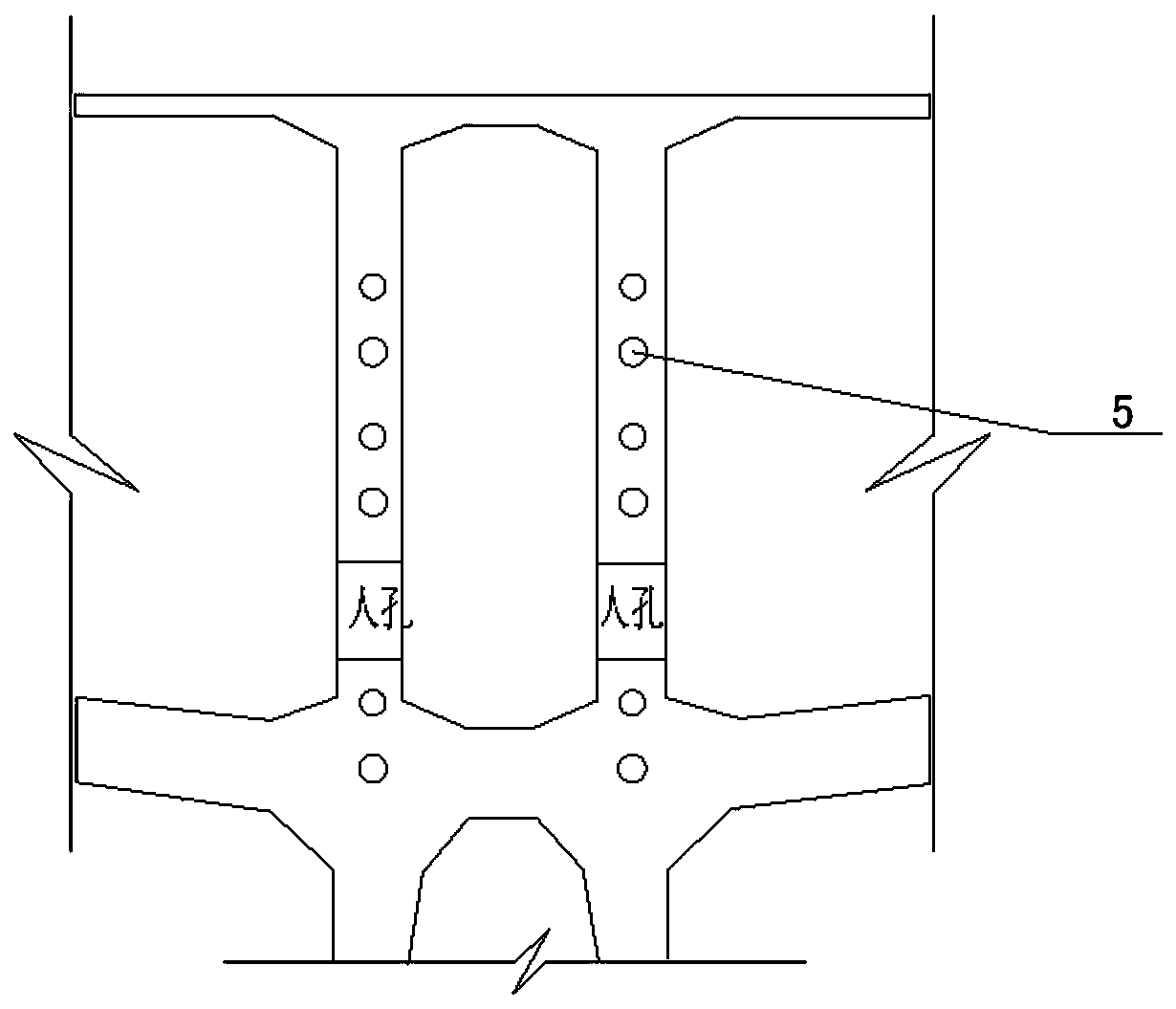

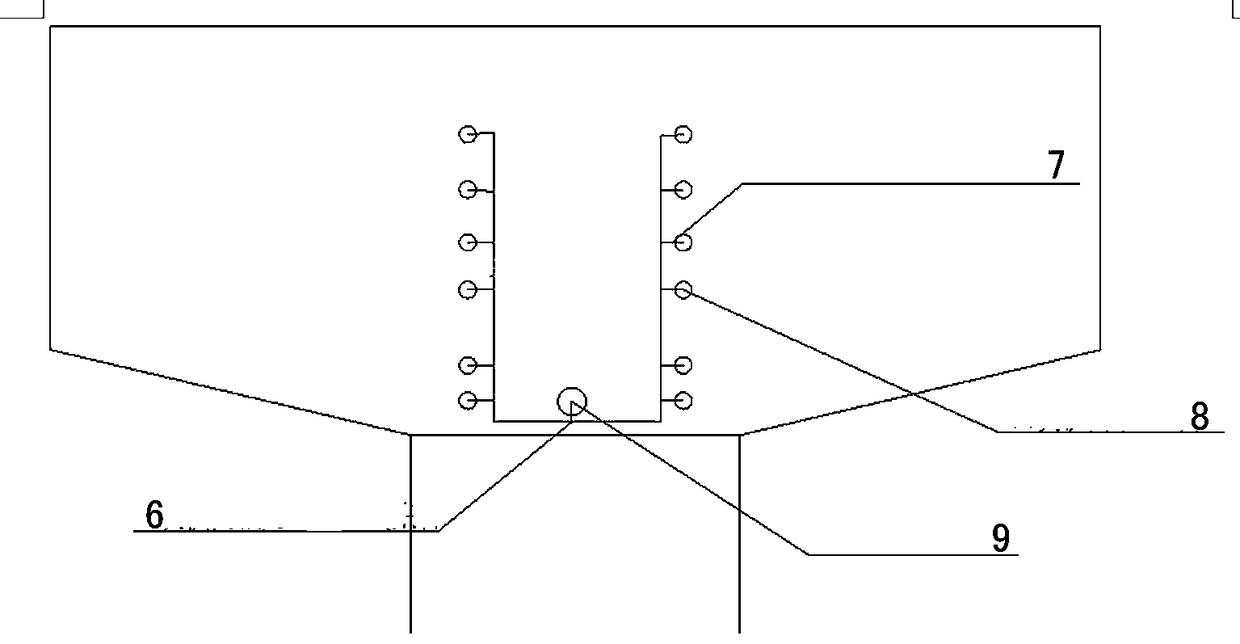

[0016] According to the overall construction process of the 0# section: install the bracket → temporarily consolidate the pier → support the bottom formwork → preload → install the permanent support → bind the bottom web reinforcement (vertical prestressed reinforcement air supply connection branch pipe installation) → support the vertical side Formwork, installation of vertical corrugated pipes, fine-rolled rebar and longitudinal corrugated pipes→supporting the inner top formwork and outer wing formwork→binding roof reinforcement, installing horizontal and longitudinal corrugated pipes (installation of web plate air supply holes)→pouring concrete → Concrete curing (open the air supply system, strictly control the internal temperature of the concrete) → tension and grouting → remove the formwork and support system.

[0017] Therefore, the present invention deploys a cold air supply system for construction while pouring the construction web. The cold air supply system includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com