Numerical control system based route offsetting method of tool path

A numerical control system, offset technology, applied in the direction of general control system, control/regulation system, program control, etc., can solve the problems of limited embedded system performance, difficult and complex calculation, difficult upgrade and maintenance, etc., to increase the convenience of work High performance, wide adaptability, easy to upgrade and maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Below in conjunction with accompanying drawing and specific embodiment the present invention is further described:

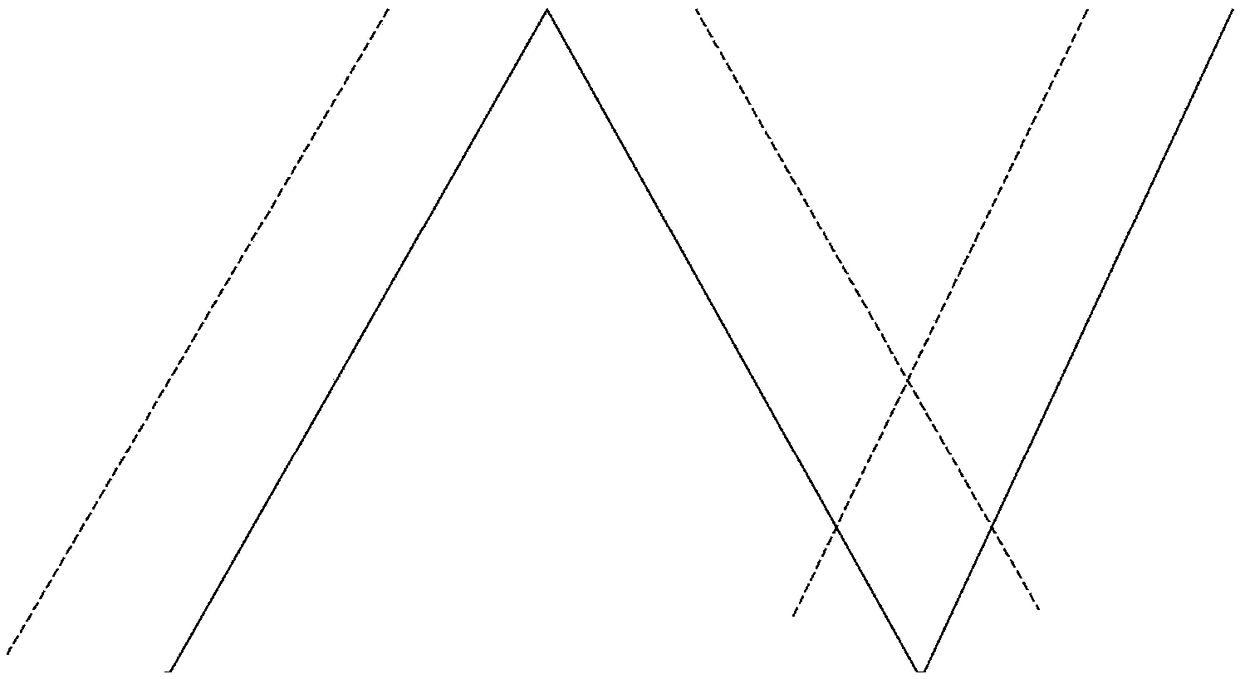

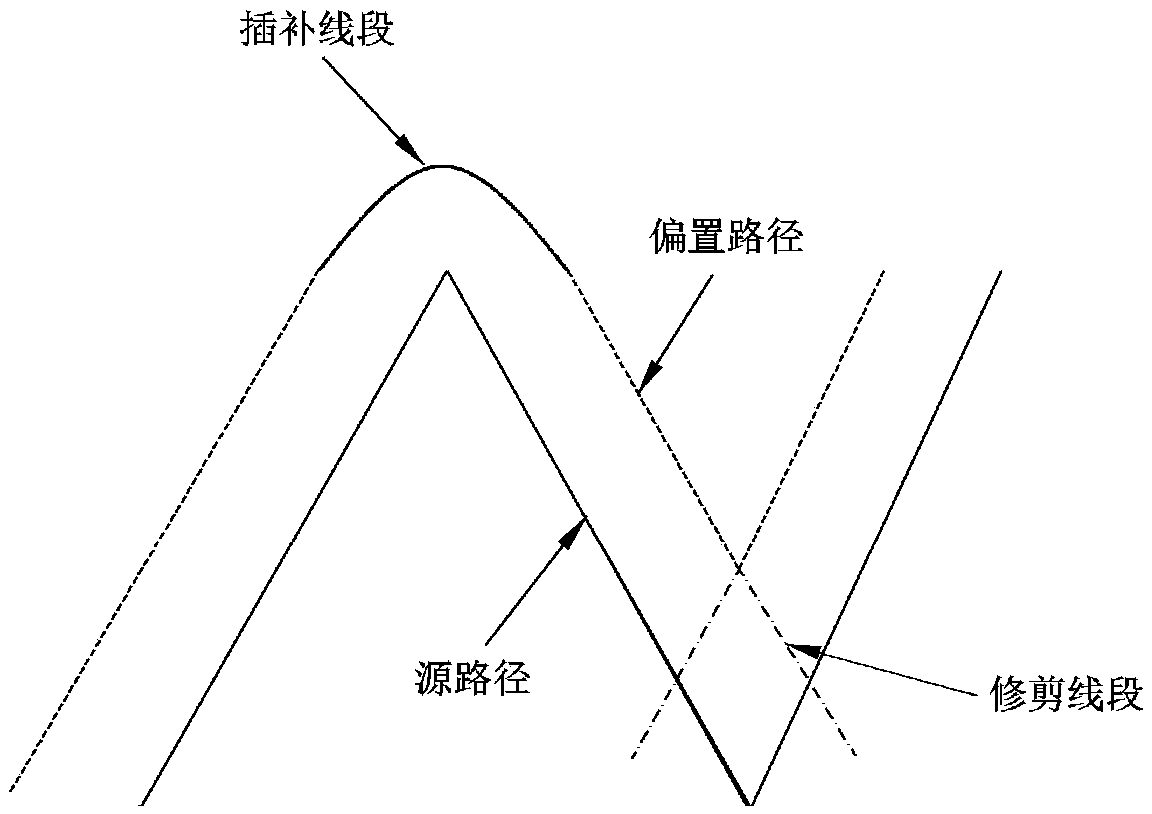

[0053] The present invention specifies the offset distance, offset direction and working plane for a given section of line path information, such as straight line, quadratic curve, cubic curve or their combination, so as to calculate its offset path information , aiming at this point, the present invention provides a kind of tool path offset path method based on numerical control system, and its specific steps include:

[0054] S1. Perform pre-processing according to the original line path information;

[0055] The pretreatment conditions include:

[0056] (1) For non-linear and circular arc lines, it is divided into several minimal line segment groups;

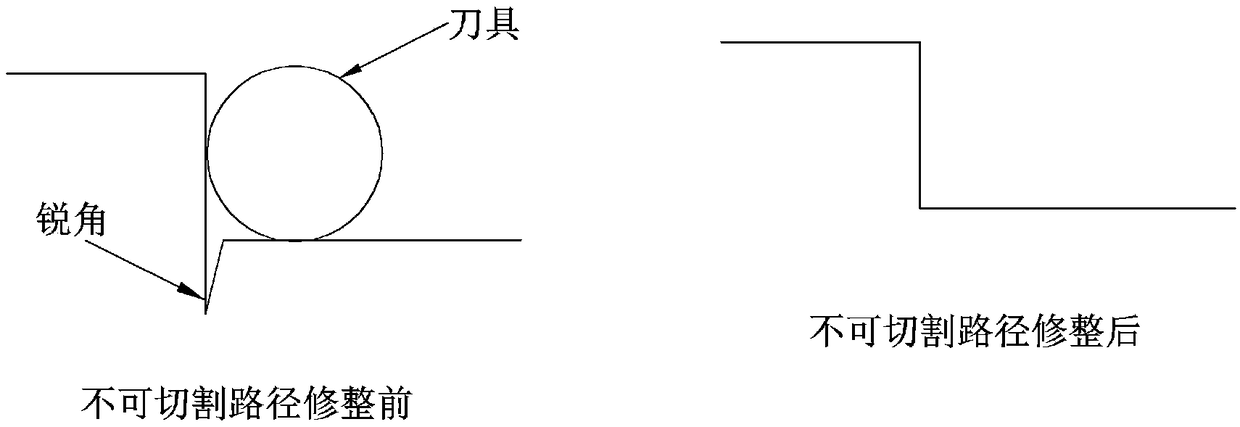

[0057] (2) For the uncuttable path, the uncuttable path refers to the path that cannot be reached by the processing tool due to the shape of the mold, and these paths cannot be cut, such as figure 1 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com