Step variable cross-section rotor flywheel energy storage system with hybrid support of permanent magnet bearings and electromagnetic bearings

A technology of electromagnetic bearing and permanent magnetic bearing, which is applied in the field of flywheel energy storage, can solve the problems of poor structure compactness of the flywheel energy storage system, increase the axial length of the flywheel rotor, and affect the dynamic characteristics of the rotor, so as to improve the rotor dynamics Features, compact system space structure size, compact structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

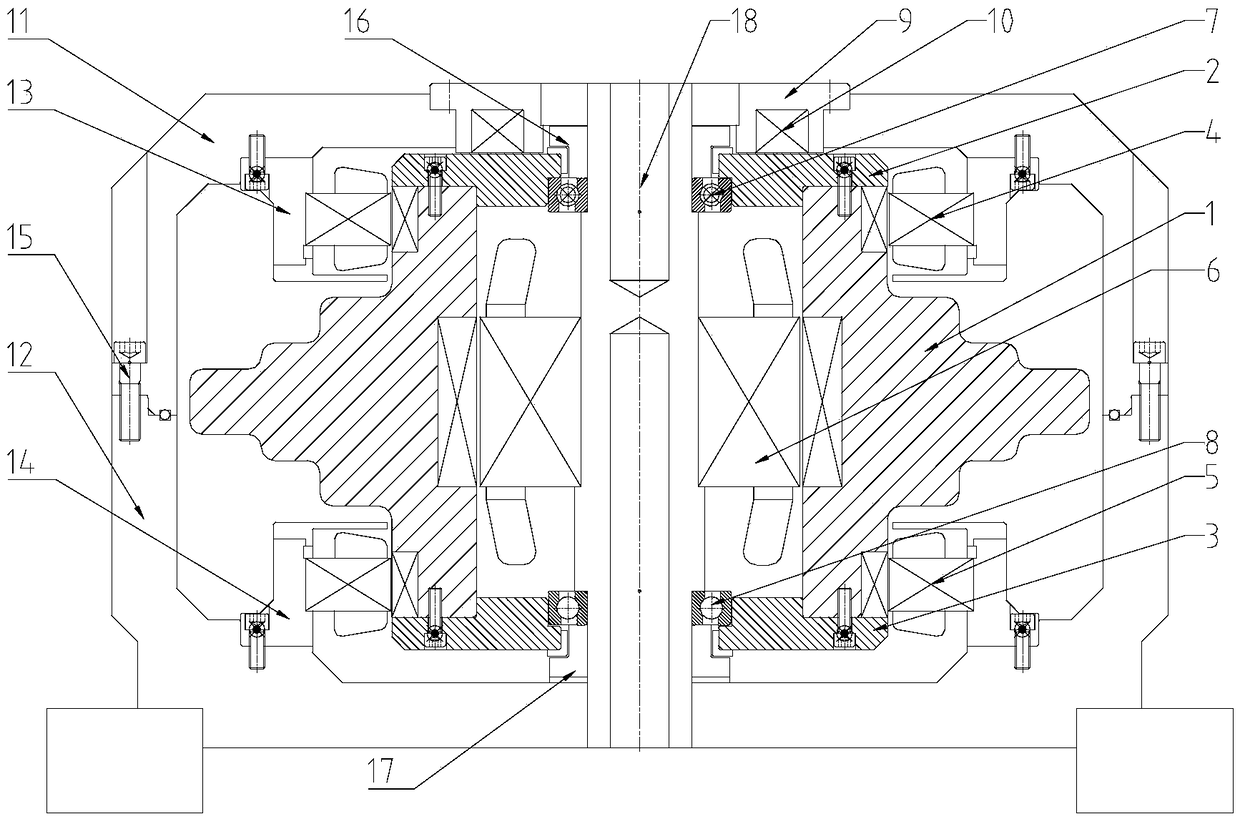

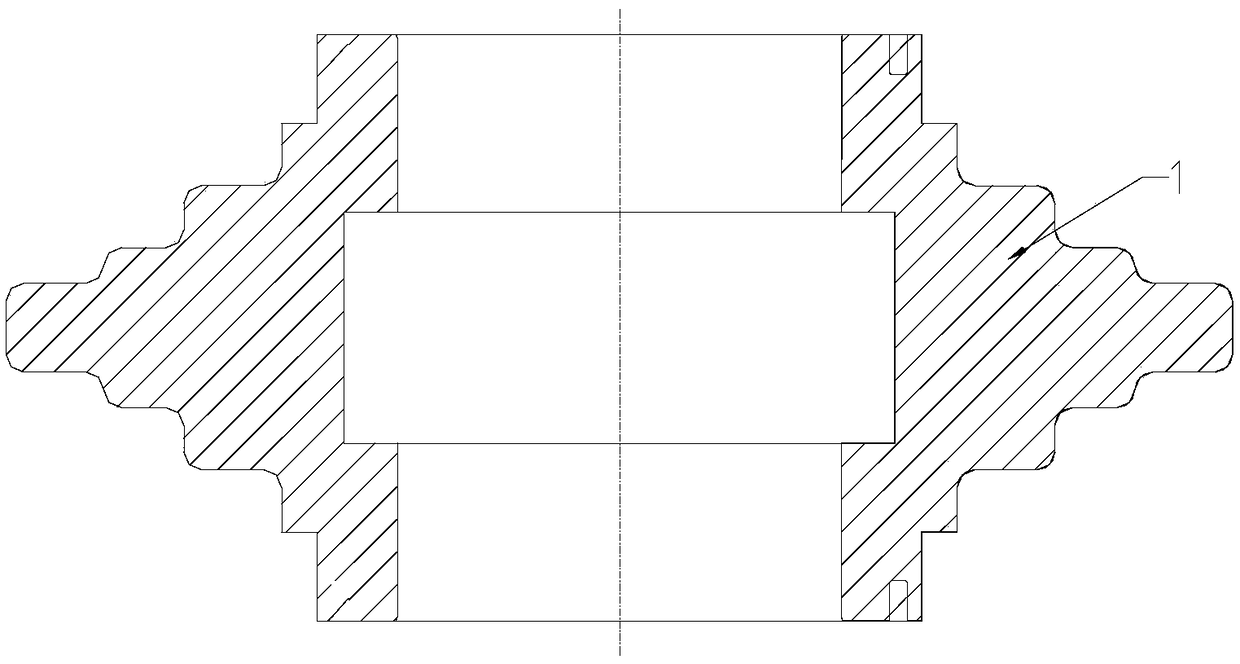

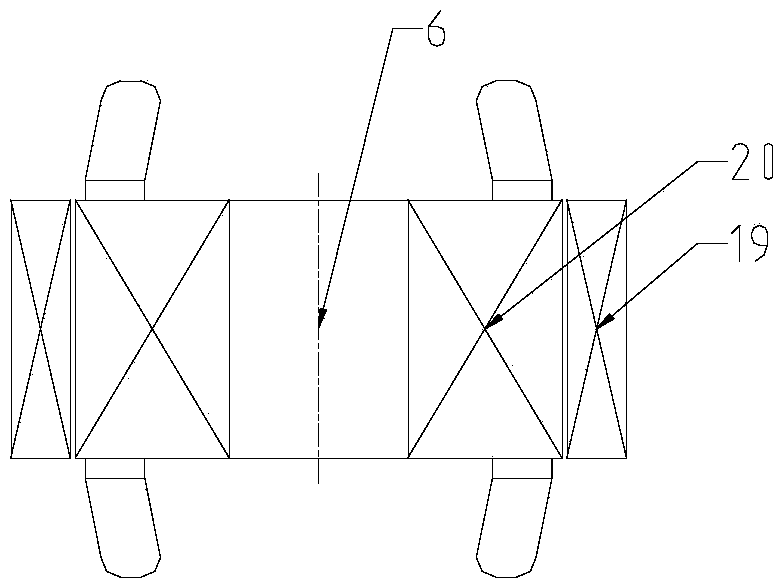

[0032] Example: see Figure 1 to Figure 5 , the energy storage system of the stepped variable cross-section rotor flywheel in this embodiment, which is supported by a mixture of permanent magnetic bearings and electromagnetic bearings, includes an energy storage and conversion part, a rotor support part and an auxiliary part; wherein, the energy storage and conversion part includes: a flywheel rotating body, an integrated Electric / power generation reciprocal bidirectional motor; the rotor support part includes: upper radial electromagnetic bearing 4, lower radial electromagnetic bearing 5, permanent magnet thrust bearing 9, upper auxiliary bearing 7, lower auxiliary bearing 8; auxiliary part includes: shell body and mandrel 18.

[0033] Among them, the integrated electric / power generation reciprocal bidirectional motor selects the outer rotor permanent magnet synchronous motor 6, the permanent magnet thrust bearing 9, the upper auxiliary bearing 7, the outer rotor permanent magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com