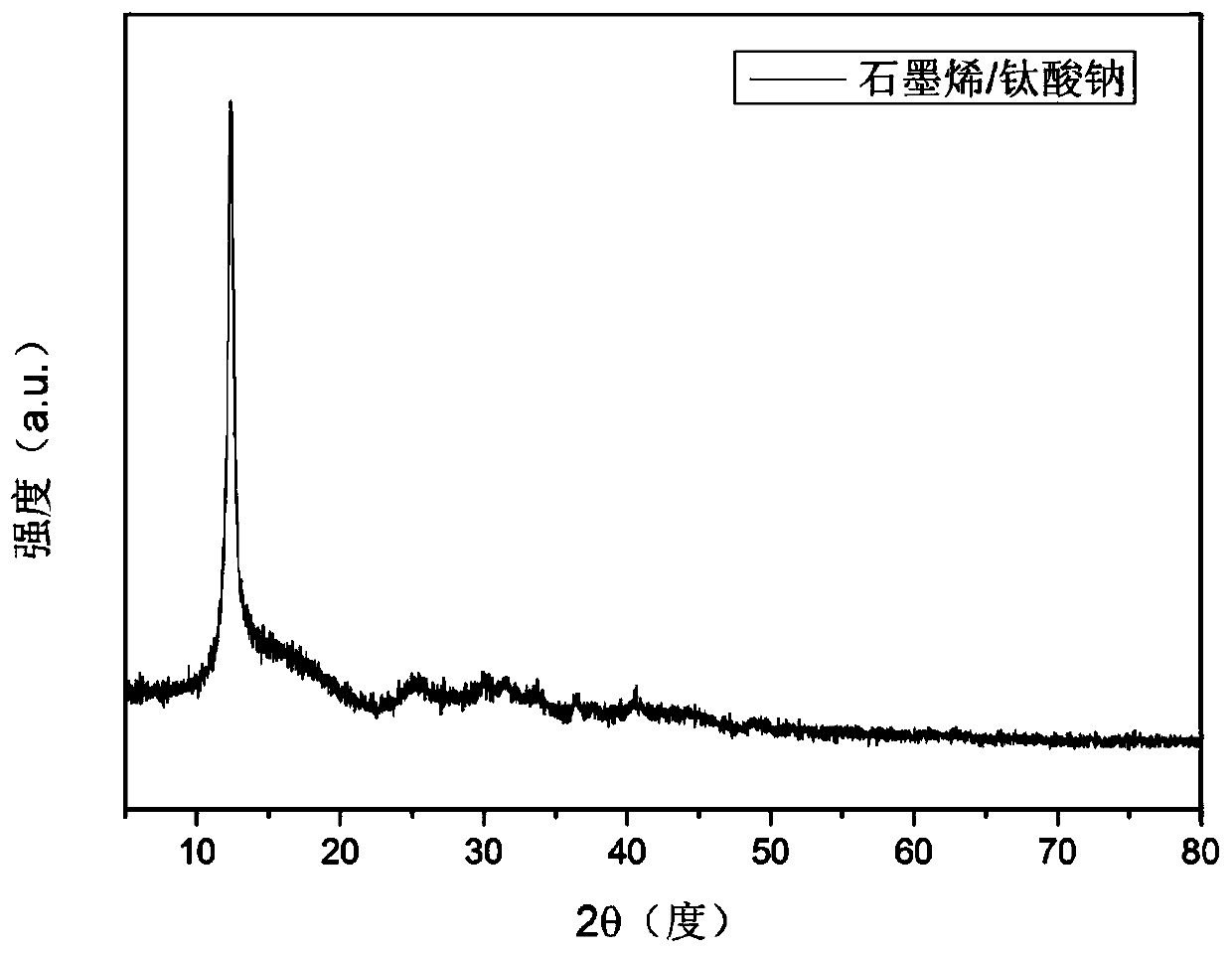

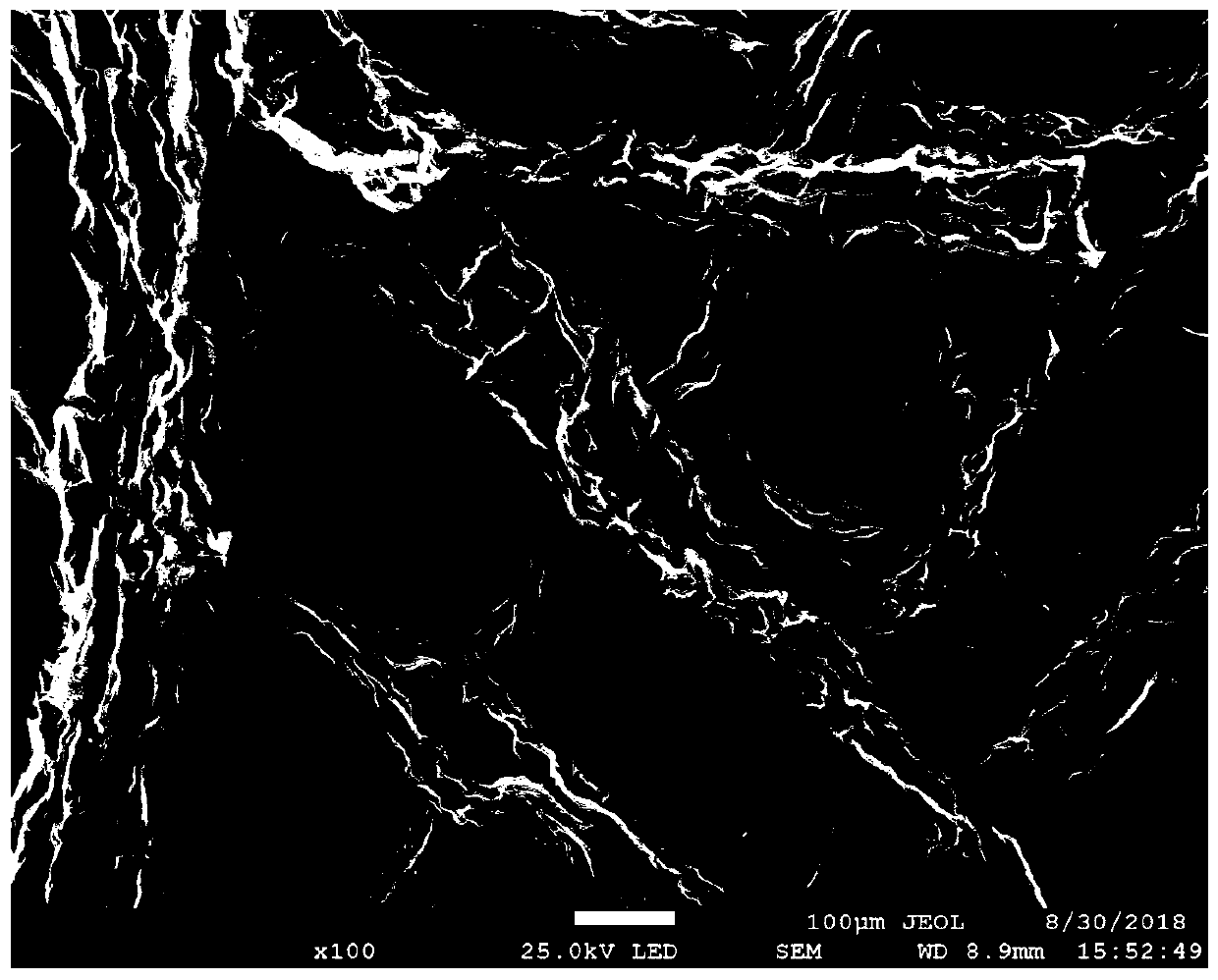

Preparation method of sodion energy storage graphene/sodium titanate non-woven fabric material

A technology of sodium titanate and graphene, which is applied in the field of sodium ion energy storage, can solve the problems of hysteresis in electrochemical reaction kinetics and poor mechanical stability of flexible negative electrode materials, and achieve high power/energy density output characteristics and enhanced mechanical properties , Improve the effect of reaction kinetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Step 1: Measure the graphene oxide aqueous solution of 1 / 4 volume of the centrifuge tube and place it in the centrifuge tube, then add 1 / 6 volume of N, N-dimethylformamide to the centrifuge tube, and place it in the In the centrifuge, the rotation speed is 8000rpm, and the centrifugation time is 20min. After centrifugation, the supernatant is drawn out, and the bottom graphene oxide is retained. The above steps were repeated three times to finally obtain a GO / DMF solution with a concentration of 5 mg / mL.

[0041] Step 2: Get 0.4g (containing 3.14mmol TiO 2 ) titanium dioxide, placed in 5 mL of aqueous sodium hydroxide solution with a concentration of 0.1 mol / L, mechanically stirred for 1 hour, then placed in a reaction kettle for hydrothermal heating at a holding temperature of 180°C for a holding time of 36 hours to obtain sodium titanate;

[0042] Step 3: washing the sodium titanate material obtained in the previous step with deionized water and ethanol successively,...

Embodiment 2

[0048] In this example, the steps of preparing the graphene / sodium titanate non-woven sodium ion storage material by wet spinning method are the same as those in Example 1, except that different masses of sodium titanate are added. Finally, graphene / sodium titanate non-woven sodium ion storage materials with different flexibility are obtained;

[0049] Step 1: Measure the graphene oxide aqueous solution of 1 / 4 volume of the centrifuge tube and place it in the centrifuge tube, then add 1 / 6 volume of N, N-dimethylformamide to the centrifuge tube, and place it in the In the centrifuge, the rotation speed is 8000rpm, and the centrifugation time is 20min. After centrifugation, the supernatant is drawn out, and the bottom graphene oxide is retained. The above steps were repeated three times to finally obtain a GO / DMF solution with a concentration of 5 mg / mL.

[0050] Step 2: Get 0.4g (containing 3.14mmol TiO 2 ) titanium dioxide, placed in 5 mL of aqueous sodium hydroxide solution...

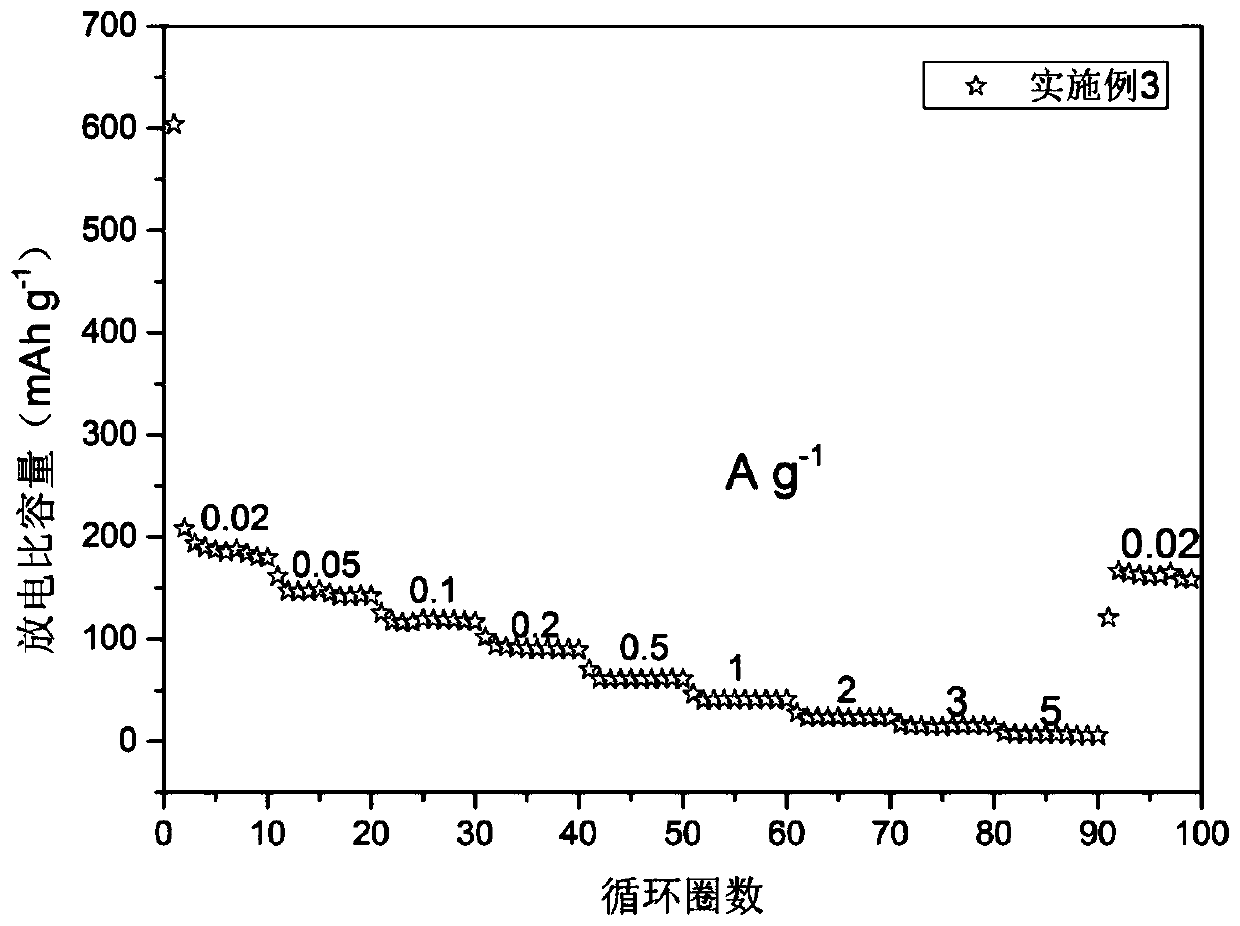

Embodiment 3

[0058] Step 1: Measure the graphene oxide aqueous solution of 1 / 4 volume of the centrifuge tube and place it in the centrifuge tube, then add 1 / 6 volume of N, N-dimethylformamide to the centrifuge tube, and place it in the In the centrifuge, the rotation speed is 8000rpm, and the centrifugation time is 20min. After centrifugation, the supernatant is drawn out, and the bottom graphene oxide is retained. The above steps were repeated three times to finally obtain a GO / DMF solution with a concentration of 5 mg / mL.

[0059] Step 2: Get 0.4g (containing 3.14mmol TiO 2 ) titanium dioxide, placed in 5 mL of aqueous sodium hydroxide solution with a concentration of 0.1 mol / L, mechanically stirred for 1 hour, then placed in a reaction kettle for hydrothermal heating at a holding temperature of 180°C for a holding time of 36 hours to obtain sodium titanate;

[0060] Step 3: washing the sodium titanate material obtained in the previous step with deionized water and ethanol successively,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com