High-voltage pulse electric field treatment device for accelerating releasing of formaldehyde in artificial wood board

A technology of high-voltage pulsed electric field and high-voltage pulsed power supply, which is applied in wood treatment, electric wood treatment, wood treatment details, etc., can solve the problems of increasing manufacturing costs, not suitable for large-scale industrial applications, secondary pollution, etc., and achieve broad application prospects , low processing cost and short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

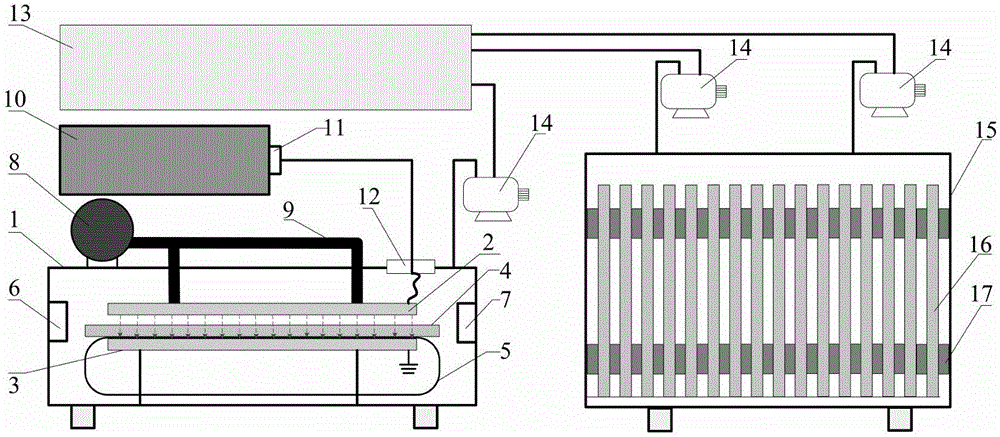

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0024] The present invention is a high-voltage pulse electric field processing device for accelerating the release of formaldehyde inside the artificial wood board, which adopts strong pulse electric field technology to accelerate the release of formaldehyde inside the artificial wood board, the pulse electric field strength is 10kV / cm to 100kV / cm, and the pulse width is 1 to 100 microns seconds, according to the different thicknesses of the plates, the output voltage of the high-voltage pulse power supply 10 can be adjusted to change the pulse electric field intensity between the high-voltage electrode 2 and the low-voltage electrode 3 .

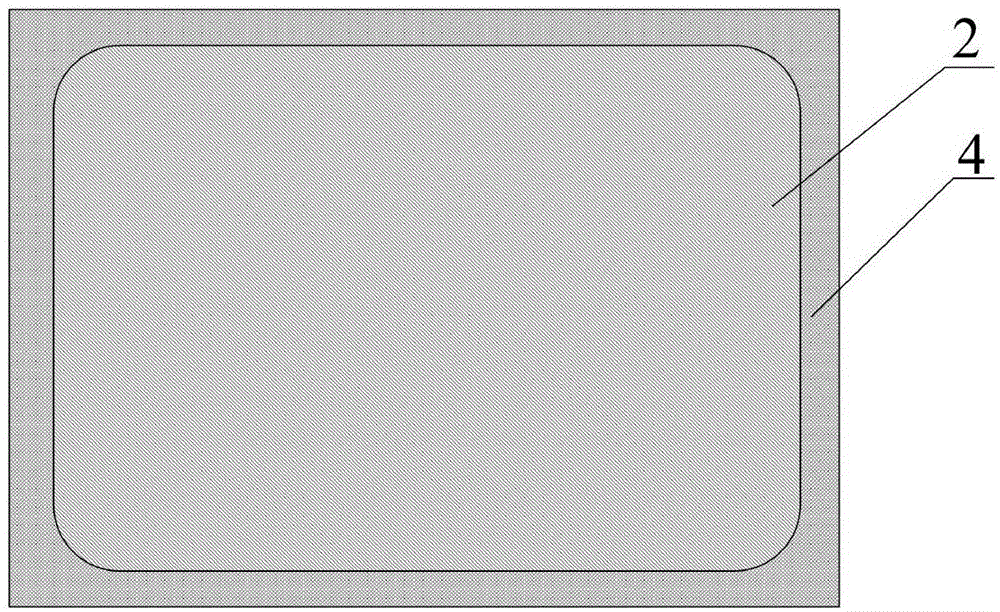

[0025] refer to figure 1 , the strong pulsed electric field treatment chamber 1 in this embodiment has a rectangular parallelepiped structure, and the strong pulsed electric field treatment chamber 1 of diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com