Polyolefin film capable of sealing repeatedly, composite cover film and preparation method thereof

A polyolefin and film technology, applied in the field of packaging materials, can solve the problems that the cover film cannot be repeatedly sealed well, cannot be sealed relatively flat, and the efficiency of packaging production is affected, so as to achieve smooth hand feeling without frustration, good Effect of mechanical strength and mechanical properties, good barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

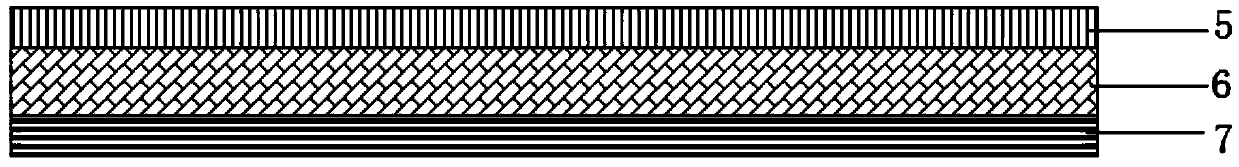

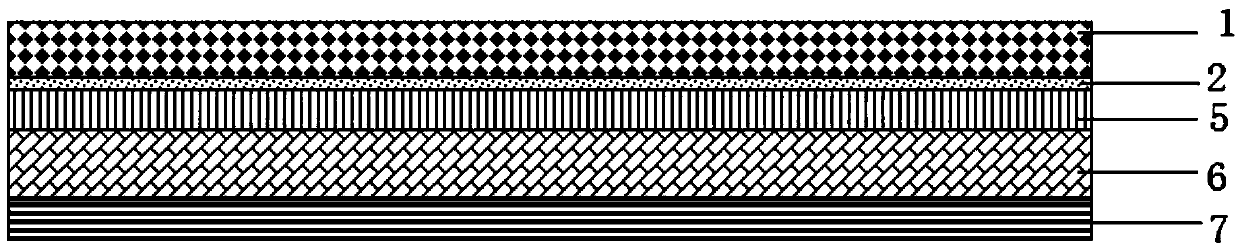

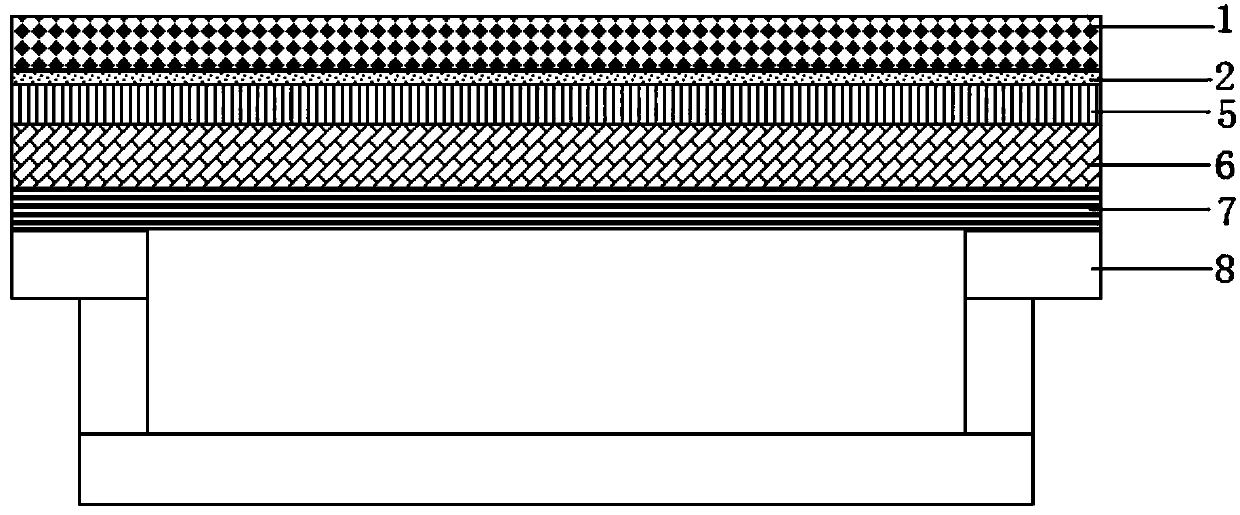

[0035] The invention provides a resealable polyolefin film, comprising:

[0036] The corona layer, the intermediate layer and the heat-sealing layer are stacked in sequence, wherein the thickness ratio of the corona layer, the intermediate layer and the heat-sealing layer is 1:(1-3):1.

[0037] In an embodiment of the present invention, the corona layer includes 100wt% polypropylene random copolymer or 40wt%-100wt% metallocene linear low-density polyethylene (mLLDPE) and 0wt%-60wt% low-density polyethylene (LDPE) The middle layer is 100wt% modified polyolefin-based polymer; the heat-sealing layer includes 0wt%-15wt% metallocene linear low-density polyethylene (mLLDPE) and 85wt%-100wt% low-density polyethylene (LDPE).

[0038] In an embodiment of the present invention, the polyolefin film is co-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com