A material fall buffer device

A buffer device and drop technology, which is applied in the direction of conveyor objects, transportation and packaging, springs/shock absorbers, etc., can solve problems such as damaged and dropped materials, and achieve the effects of alleviating impact, reducing maintenance costs, and reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

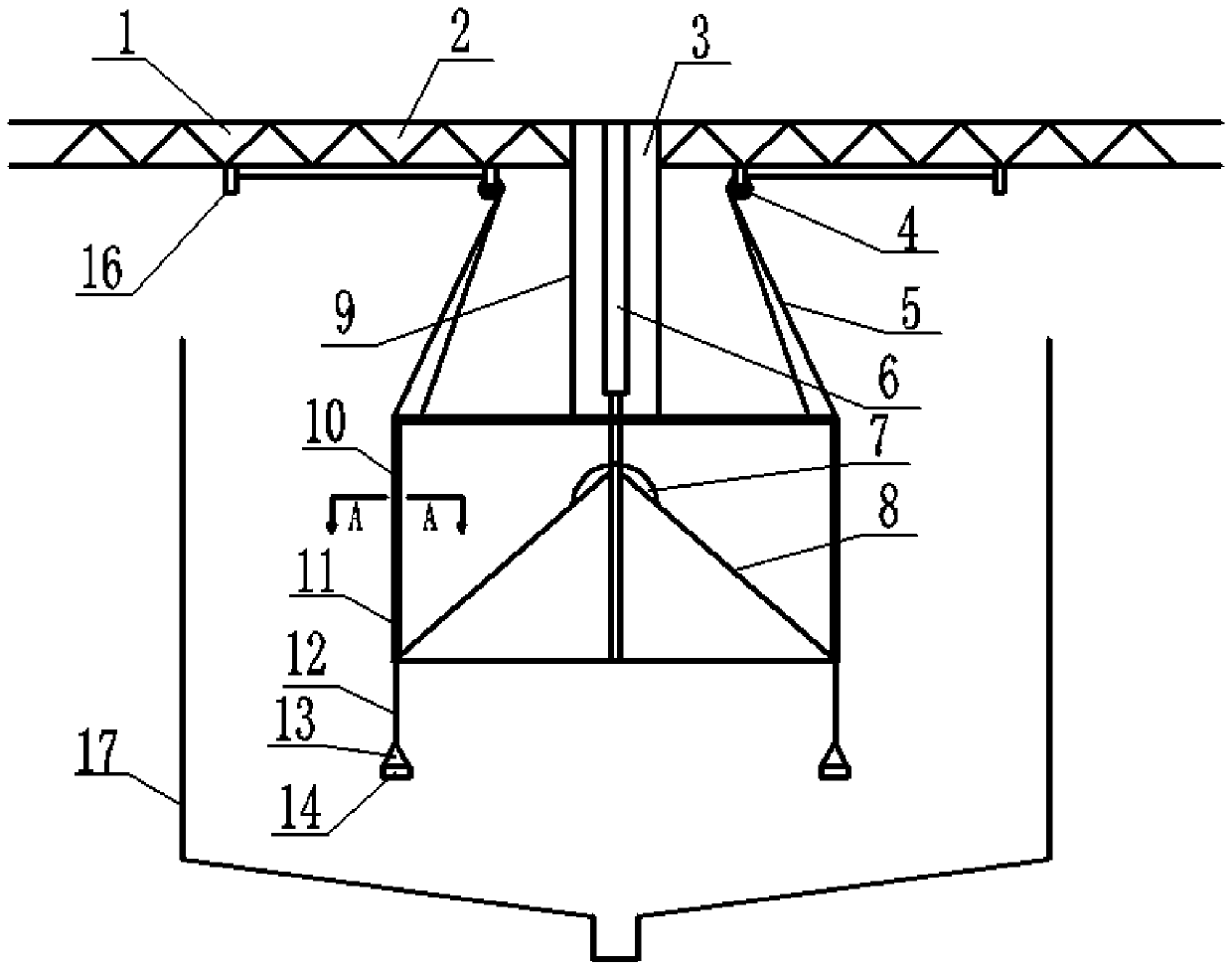

[0027] Such as Figure 1-3 As shown, the present invention provides a material fall buffer device, including: a transmission device and a lifting device, the transmission device includes a crane 1, a conveyor belt 2 is provided inside the crane 1, and gaps are provided at both ends of the crane 1, A baffle is provided at the notch, and a material guide groove 3 is provided at the baffle.

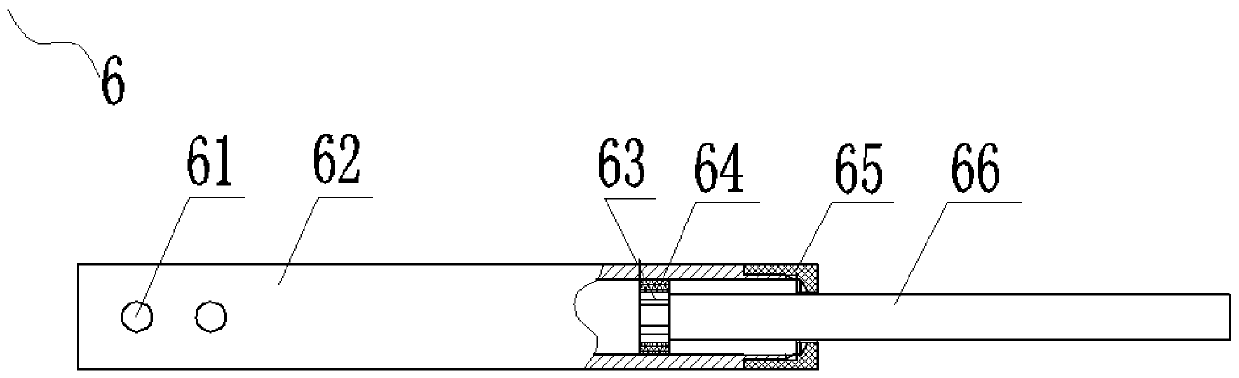

[0028] The lifting device comprises a damping device 6, a casing 10, a netway and a spring rope 5.

[0029] The network channel uses flexible network channel 9 to prevent the material from being damaged by the network channel during the falling process. The top of the flexible network channel 9 is connected to the crane 1 and is located directly below the material guide trough 3, which is used to realize the material directly passing through the material guide. The groove 3 falls into the channel of the flexible network channel 9, the bottom end of the flexible network channel 9 is connecte...

Embodiment 2

[0034] In order to achieve stable and safe lifting of the box body 10 under the traction of the spring rope 5 , the material fall buffer device provided by the present invention is provided with two spring ropes 5 on both sides of the box body 10 .

Embodiment 3

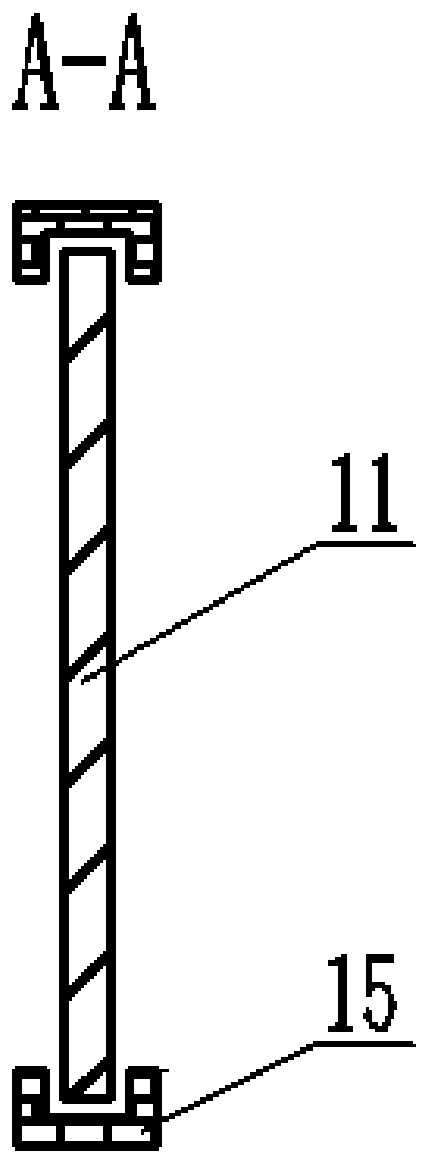

[0036] In order to realize the sliding of the box door 11 through the deformation of the rubber pad 14 due to pressure, two legs 12 are provided at the bottom of each box door 11 .

[0037] working principle

[0038] Materials such as potatoes and apples are transported to the gaps at both ends of the crane 1 through the conveyor belt 2 fixed inside the crane 1, and are blocked by the baffle, falling from the gap to the material guide trough 3, and through the material guide trough 3 to the Inside the flexible network channel 9, the material falls along the flexible network channel 9, falls on the buffer pad 7 fixed on the top of the inclined chute 8, and is cushioned, and the material slides into the box body 10 along the inclined chute 8 without damage. With the accumulation of materials, the box body 10 will become heavier and heavier, and the box body 10 will gradually move downward. , the rubber pad 14 will be deformed to generate an upward thrust, the rubber pad 14 push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com