Ore blending method for reducing consumption and discharge of iron ore sintering carbon

A technology of carbon and ore blending, applied in the field of iron ore powder sintering, can solve the problems of inability to effectively characterize the sintering performance of iron ore powder, achieve the effect of reducing consumption and emissions, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

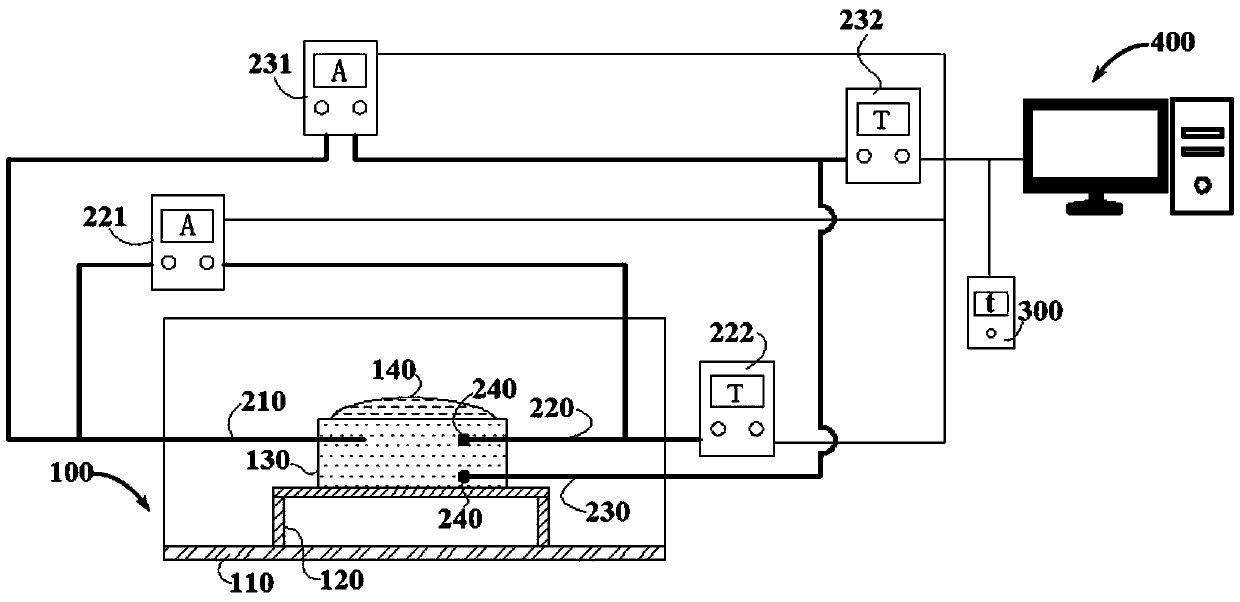

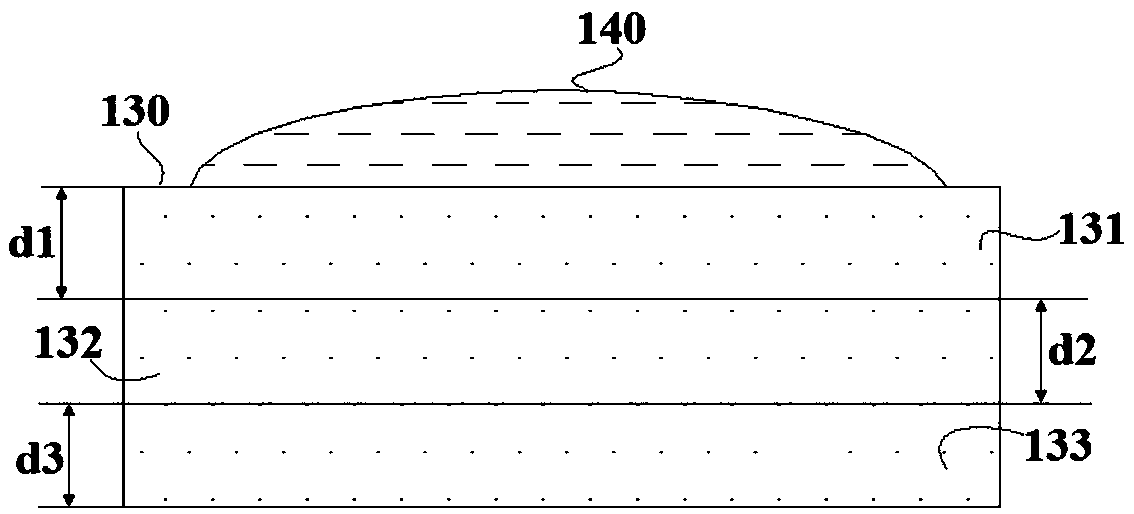

[0044] combine Figure 12 Shown, a kind of ore blending method of reducing iron ore sintering carbon consumption and emission of the present invention, at first controls the assimilation reaction characteristic number A of mixed ore h 50-80, and then according to Calculate the ratio r of iron ore fines i . Among them, A i is the characteristic number of assimilation reaction of a single iron ore powder; r i is the ratio of a single iron ore powder; m is the number of iron ore powders, m≥2. By controlling the assimilation reaction characteristic number A of mixed ore h 50-80, combined with the assimilation temperature and assimilation speed of iron ore powder to carry out ore blending, can reduce the carbon consumption and emission of iron ore sintering, and further realize energy saving and emission reduction in the sintering process. The specific steps of the ore blending method for reducing the carbon consumption and discharge of iron ore sintering of the present inve...

Embodiment 2

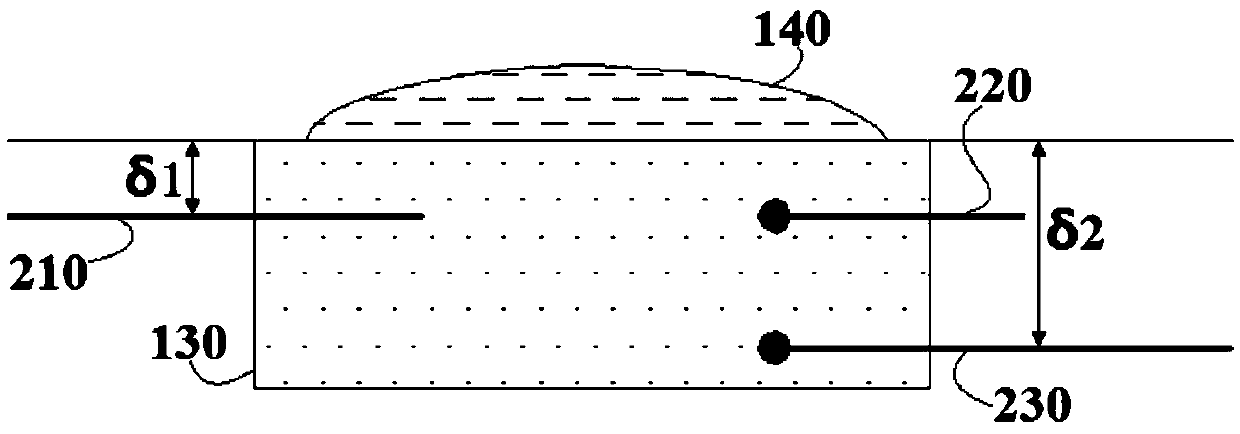

[0104] combine Figure 5-11 As shown, the content of this embodiment is basically the same as that of Embodiment 1. The difference is that the detection device of this embodiment also includes a reaction timer 310, and the reaction timer 310 is electrically connected to the control processing unit 400. The reaction timer 310 The reaction process is timed, so that the time taken for the iron ore powder sample 140 and the calcium oxide tablet 130 to react to the third electrode 230 can be known, and the assimilation can be obtained by calculating the ratio of the distance between the electrodes to the time used for the reaction. reaction speed. In the process of detecting the assimilation reaction in this implementation, when the temperature measurement part a222 detects that the temperature rises to 1150 ° C, the timer 300, the detection part a221 and the temperature measurement part a222 are turned on. At this time, the second detection unit is in the closed state, and the rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com