Steam internal-combustion engine

A technology of internal combustion engine and steam, applied in the direction of internal combustion piston engine, combustion engine, mechanical equipment, etc., can solve problems such as difficult to reassemble, lack, and fail to improve the actual efficiency of internal combustion engines, and achieve the effect of reducing consumption and emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific embodiments. It should be understood that the following examples are only used to illustrate the present invention but not to limit the scope of the present invention.

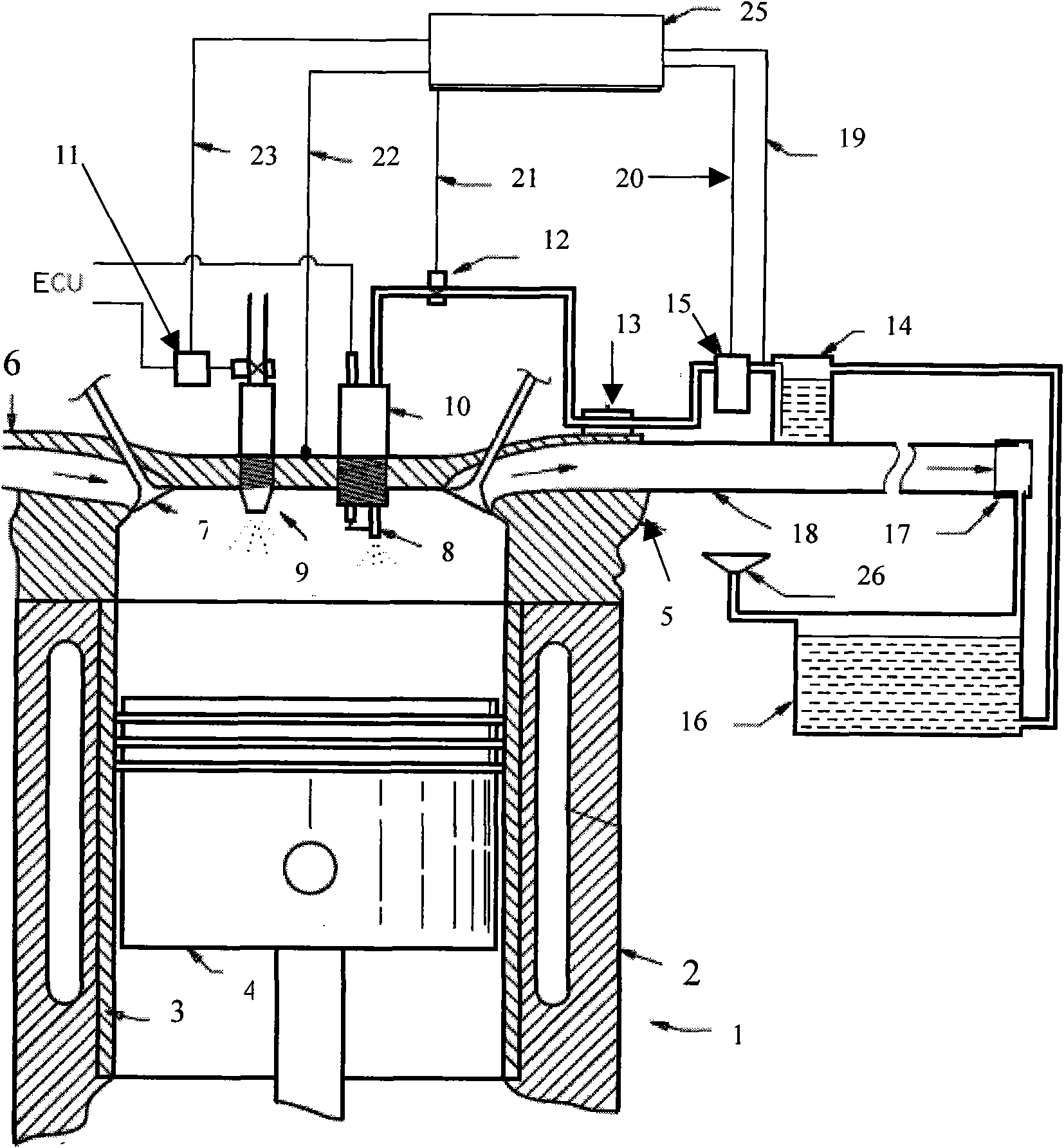

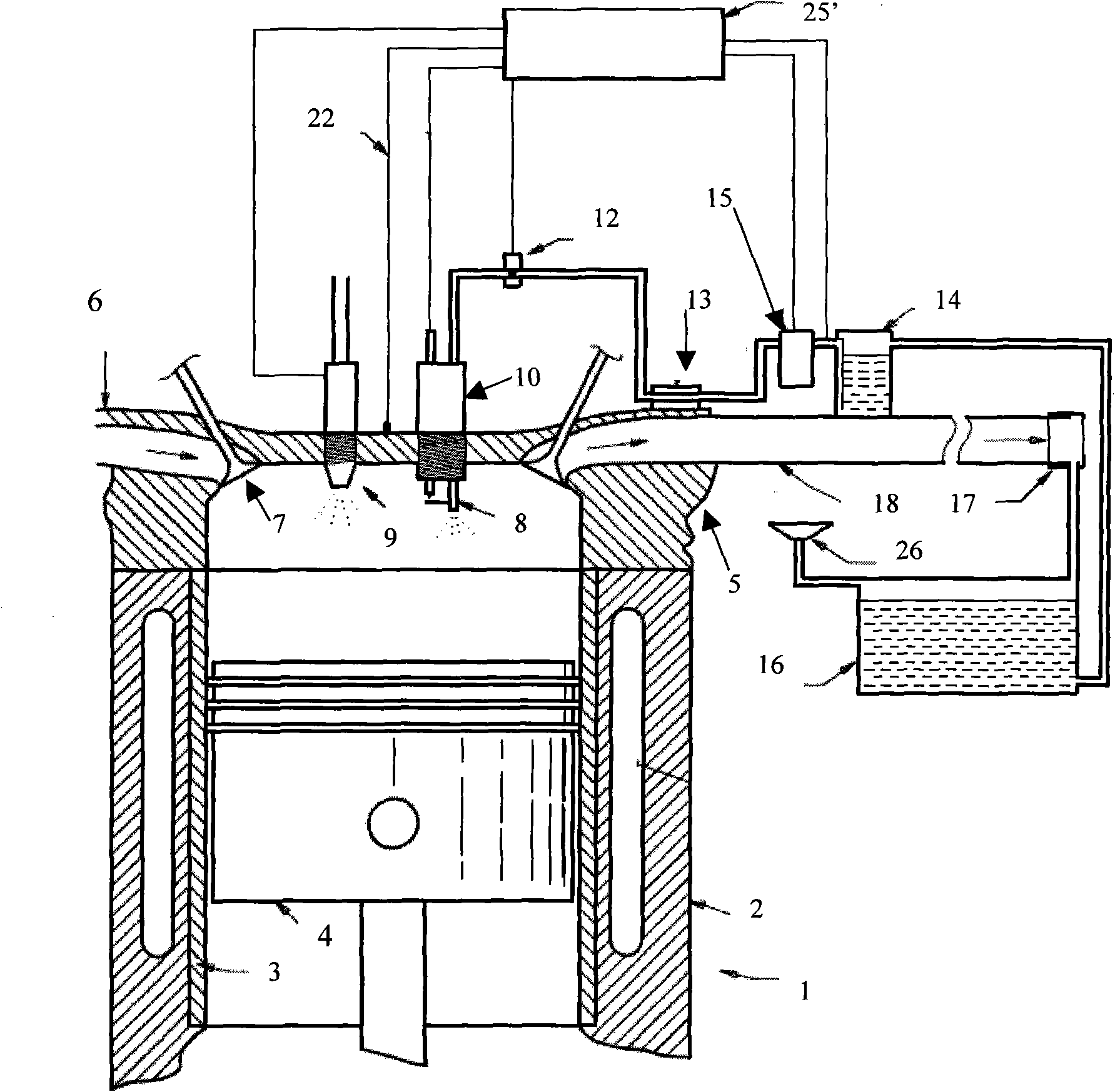

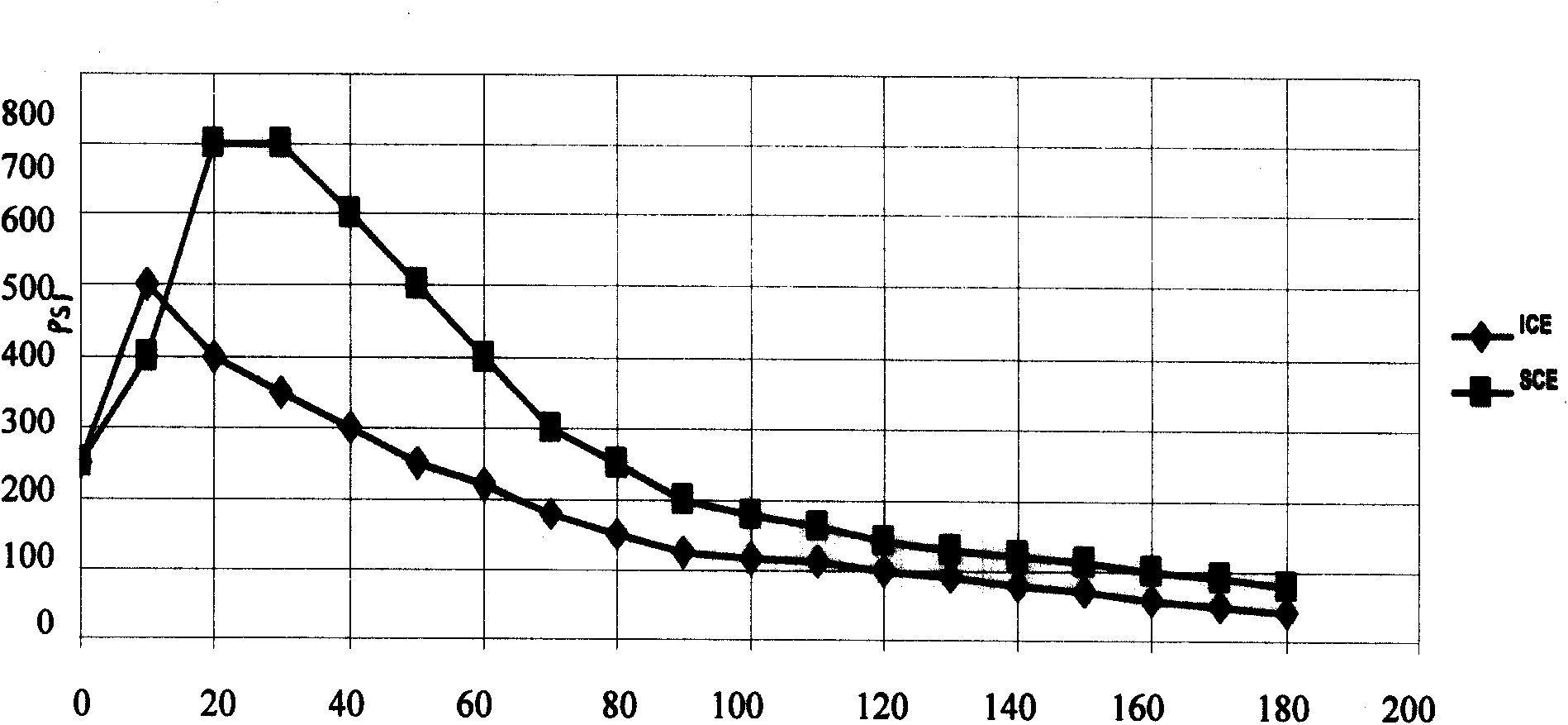

[0022] The steam internal combustion engine provided by this application is to inject preheated water into the combustion chamber, evaporate the water into a pressurized steam mass to generate mechanical work, improve the fuel efficiency of existing cars or new cars, and thus reuse waste heat—when The engine reaches a preset temperature limit, and during the ignition cycle of the air-fuel mixture, water is sprayed into the combustion chamber to burn with the air-fuel mixture to enhance the power stroke.

[0023] The steam internal combustion engine provided by the present invention can be used to refit the steam internal combustion engine of the existing common internal combustion engine, and can also be used for the stea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com