Clothes processing equipment and control method thereof

A technology of clothes processing equipment and a control method, which is applied to the control device of washing machines, other washing machines, household clothes dryers, etc., which can solve problems such as fire hazards, non-integrated effects, general user experience, etc., and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1 provides a method for controlling laundry processing equipment. The laundry processing equipment includes at least one washing device and at least one drying device, the washing device includes a water heater for heating washing water, and the drying The device includes a drying heater for heating the air entering the drying device, wherein, when both the washing water heating program and the drying program need to be executed, the laundry treatment device controls the water heater and the drying heater not to work at the same time, Or adjust the power of the water heater and the drying heater so that both can work at the same time.

[0054] In the above solution, the user can issue different heating control commands at the same time or at any time, and the laundry processing equipment automatically controls and executes the control commands issued by the user to ensure that the laundry processing equipment can work safely within the rated power, preventing ...

Embodiment 2

[0081] The second embodiment provides a laundry treatment device adopting the control method in the first embodiment above, the laundry treatment device includes at least one washing device and at least one drying device, and the washing device includes a water heater for heating the washing water The drying device includes a drying heater for heating the air entering the drying device, the washing devices and drying devices are powered by the same power line, and the laundry processing equipment also includes The control board, the washing device and the drying device are all connected to the control board, and the control board controls the water heater and the drying heater to not work at the same time, or adjusts the water heater and the drying heater. Power enables both to work simultaneously.

[0082] In the above solution, the control board controls and coordinates the work of each heater, preventing the clothes processing equipment from running with superpower when mul...

Embodiment approach

[0090] The first implementation mode:

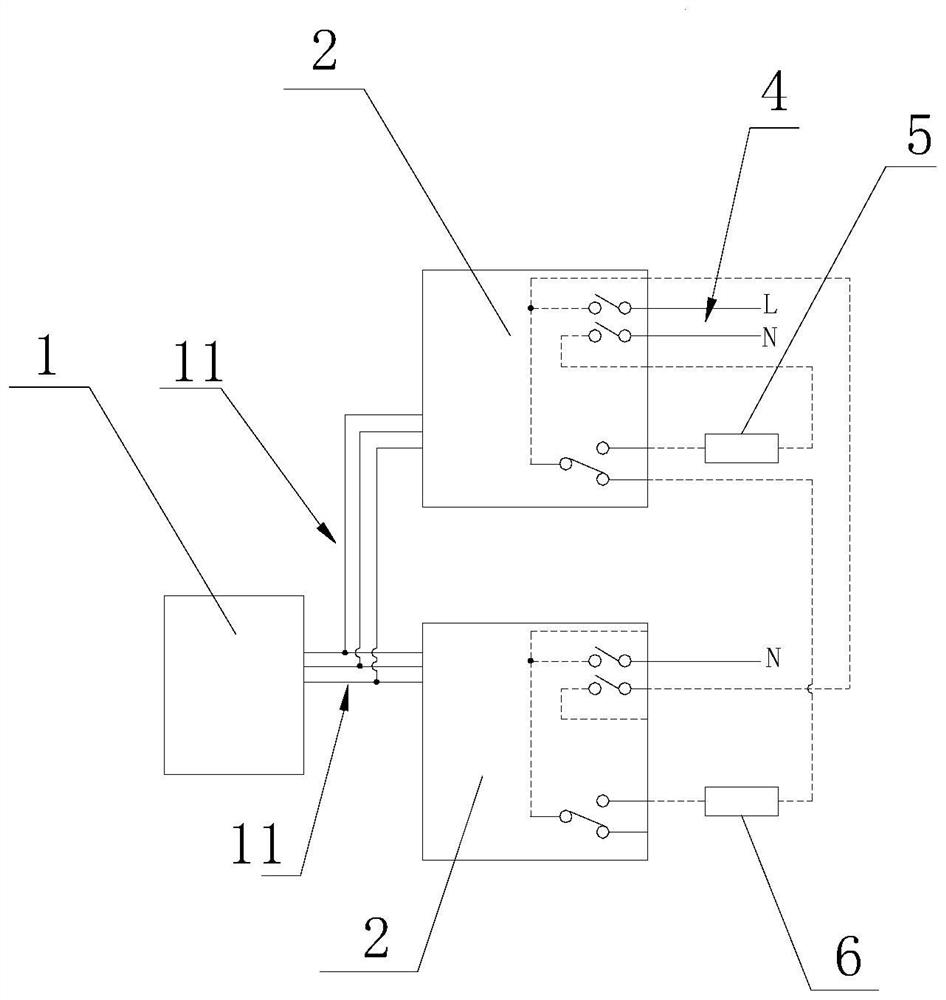

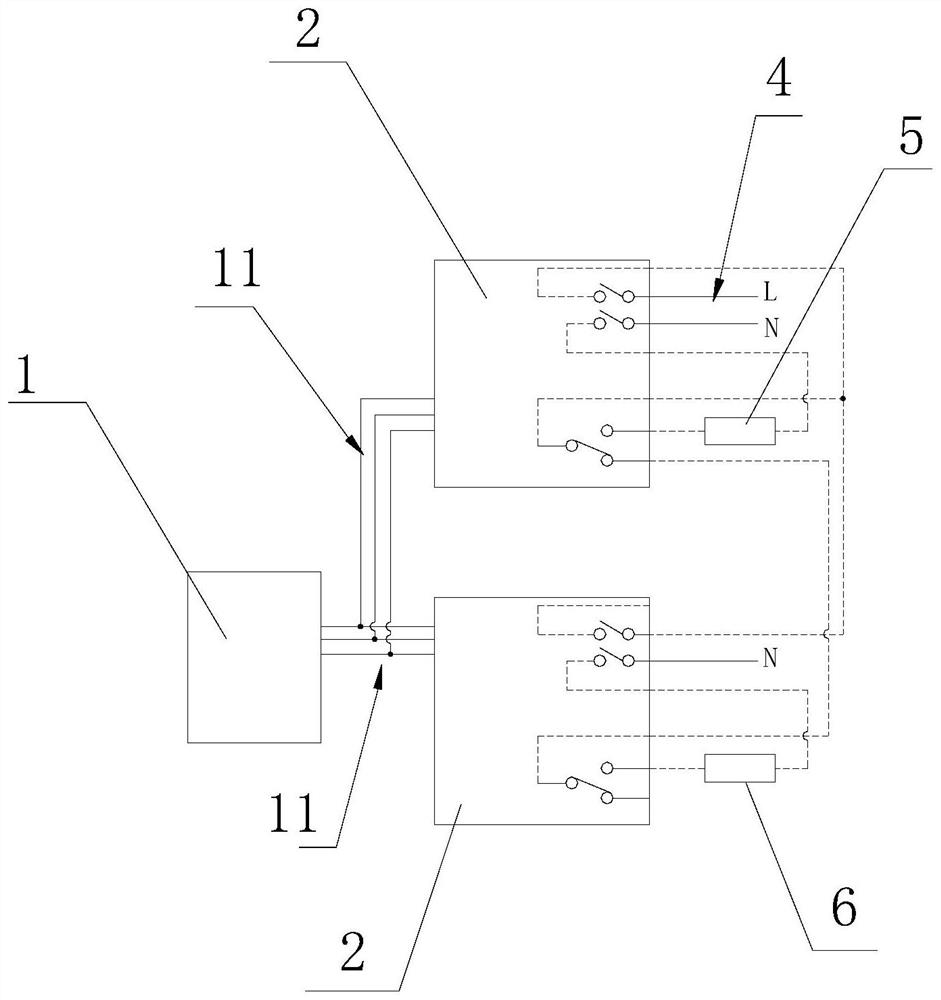

[0091] see figure 1 and figure 2 As shown, the laundry processing equipment includes a control board 1 and several power boards 2 (two power boards are illustrated in the figure), wherein the control board 1 and each power board 2 are electrically connected through a bus 11, wherein the washing device corresponds to The power board (the above is the first power board) is connected to the water heater, the power board corresponding to the drying device (the above is the second power board) is connected to the drying heater, one of the power boards is the main power board, and the clothes processing equipment Each washing device and drying device share a power line 4, and the power line 4 is connected to the main power board, and each power board 2 is respectively provided with at least one main relay.

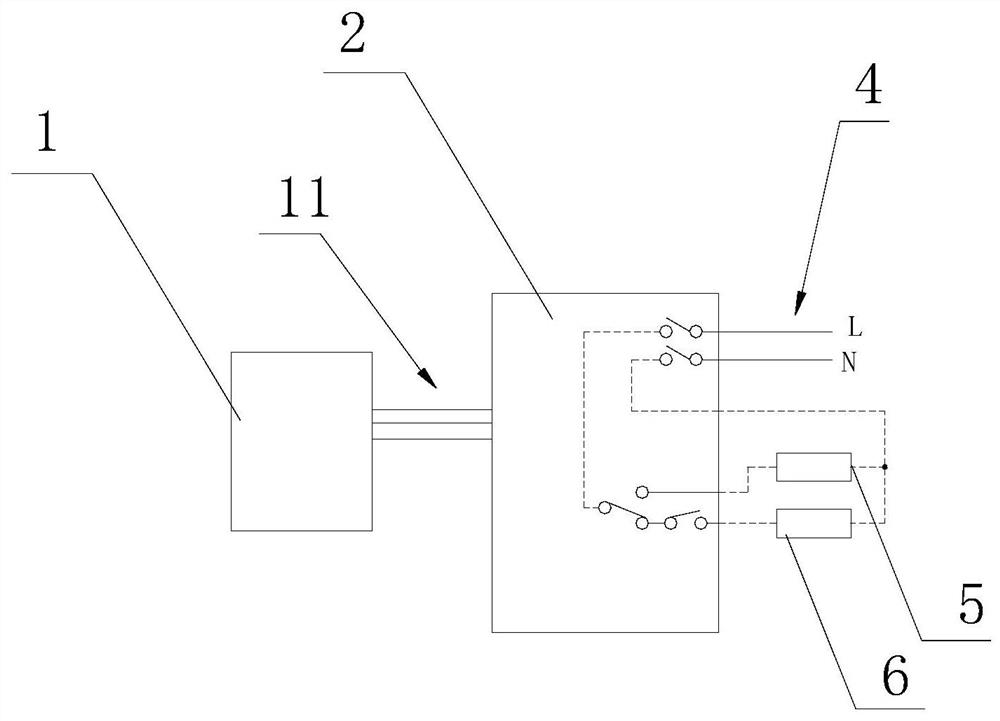

[0092] For another implementation, see image 3 and Figure 4 As shown, the laundry processing equipment includes a control board 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com