FRP and reinforced plastic co-extruded door and window profile

A technology of reinforced plastics and door and window profiles, applied in the direction of window/door frame, wing leaf frame, etc., can solve the problems of high market price and inapplicability, and achieve the effect of improving deformation resistance, strength and heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

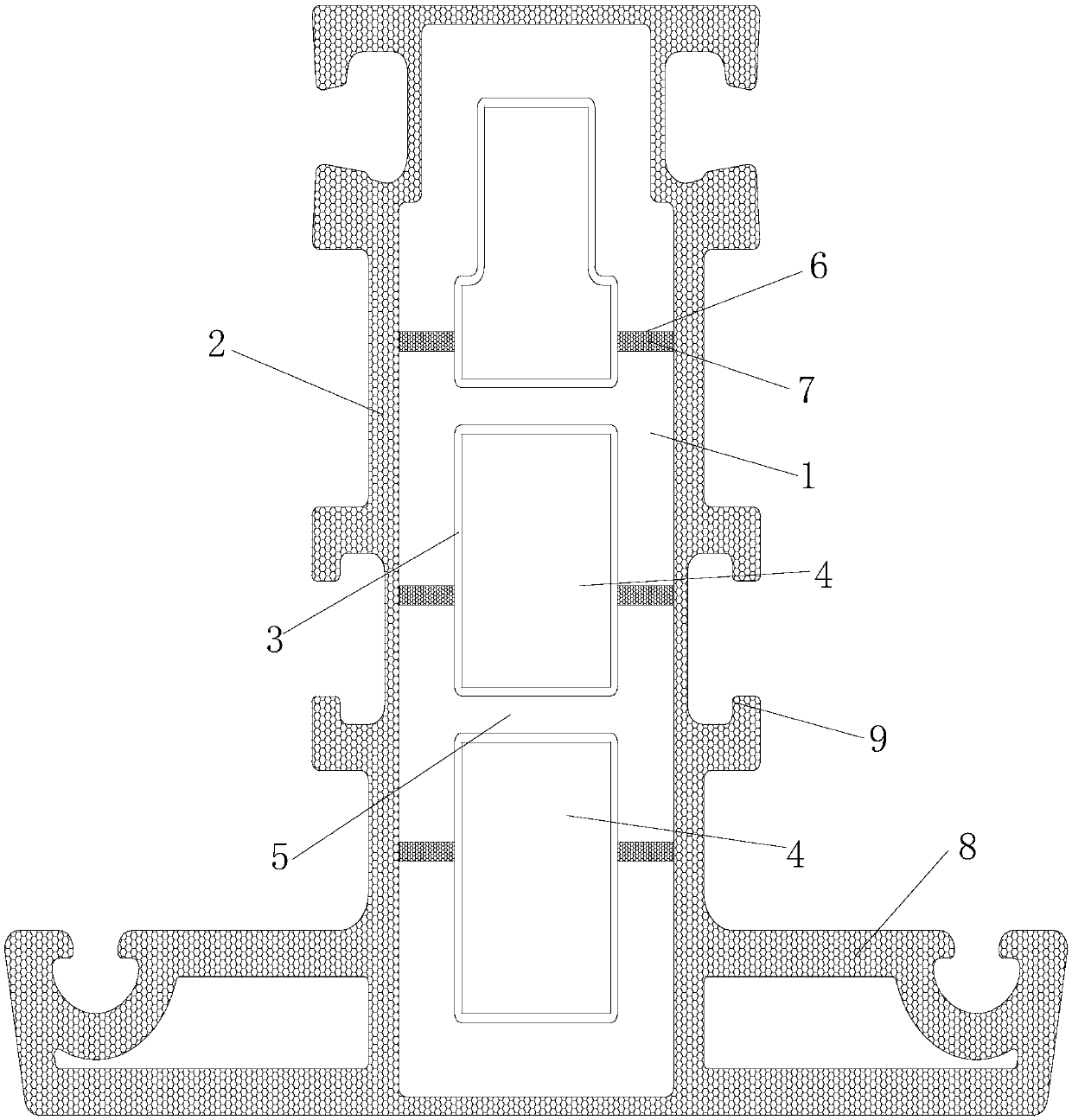

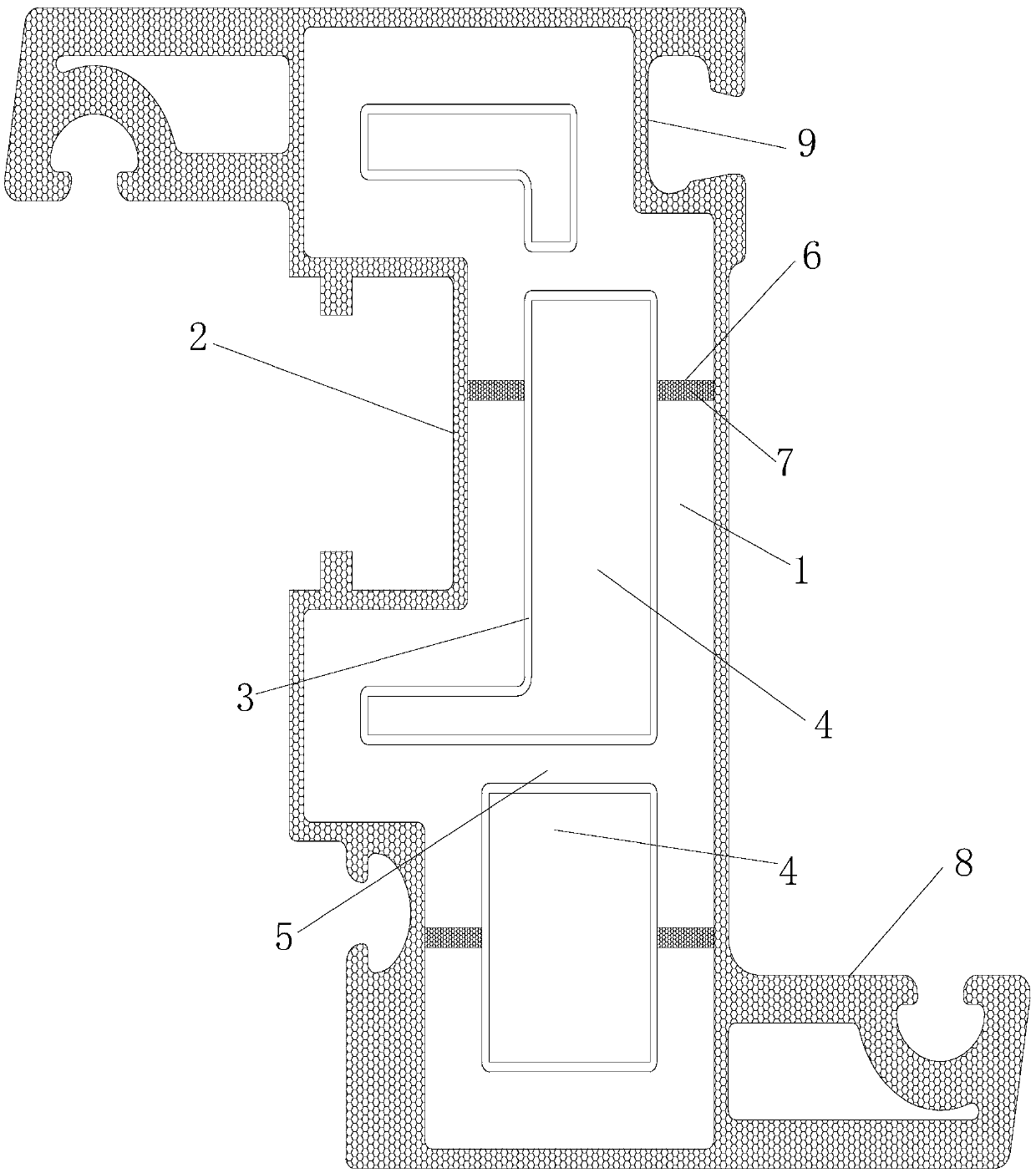

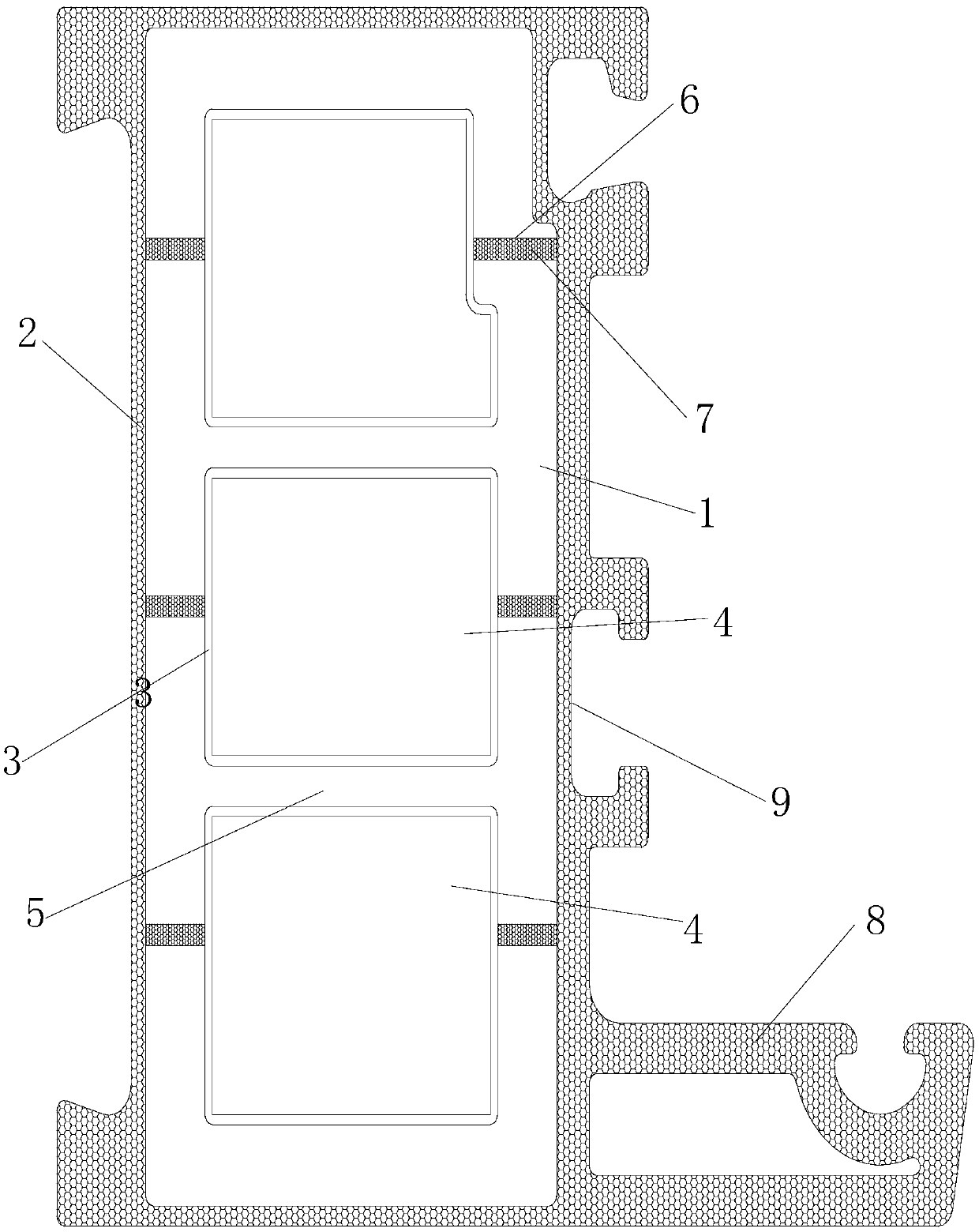

[0024] Such as Figure 1 to Figure 3 The shown FRP and reinforced plastic co-extruded door and window profiles include an inner liner made of FRP, the outer surface of the inner liner is wrapped with a surface layer made of hard plastic through co-extrusion, and the inner liner is provided with a void cavity, and reinforcing ribs are provided in the cavity; the walls of the cavity and the surfaces of the reinforcing ribs are provided with low-emissivity layers. Specifically, the wall thickness of the lining is 4mm. The number of the reinforcing ribs is two, and the two reinforcing ribs divide the cavity into three sub-cavities that may be equal or unequal in size, so as to further ensure the strength of the lining. Wherein, the thickness of the reinforcing rib is 2 mm.

[0025] The outer surface of the inner liner is covered with the hard plastic in the molten state to form a surface layer by means of co-extrusion. In the process of making the surface layer, the side wall o...

Embodiment 2

[0038] This FRP and reinforced plastic co-extruded door and window profile is the same as Example 1 except for the following technical features:

[0039] The low-emissivity layer is made of metal foil with emissivity less than 0.6. In this embodiment, the metal foil is made into a low-emissivity layer on the inner surface of the inner liner and the surface of the reinforcing rib by co-extrusion and attachment molding, so that the heat insulation performance of the entire door and window profile can be improved like the coating in Example 1. Metal foil can be gold foil or silver foil or aluminum foil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com