Supercritical carbon dioxide cooling system and control method thereof

A carbon dioxide and cooling system technology, applied in the field of metal processing, can solve problems such as unreliable intelligence and pipeline blockage, and achieve the effect of reliable intelligence and avoiding blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

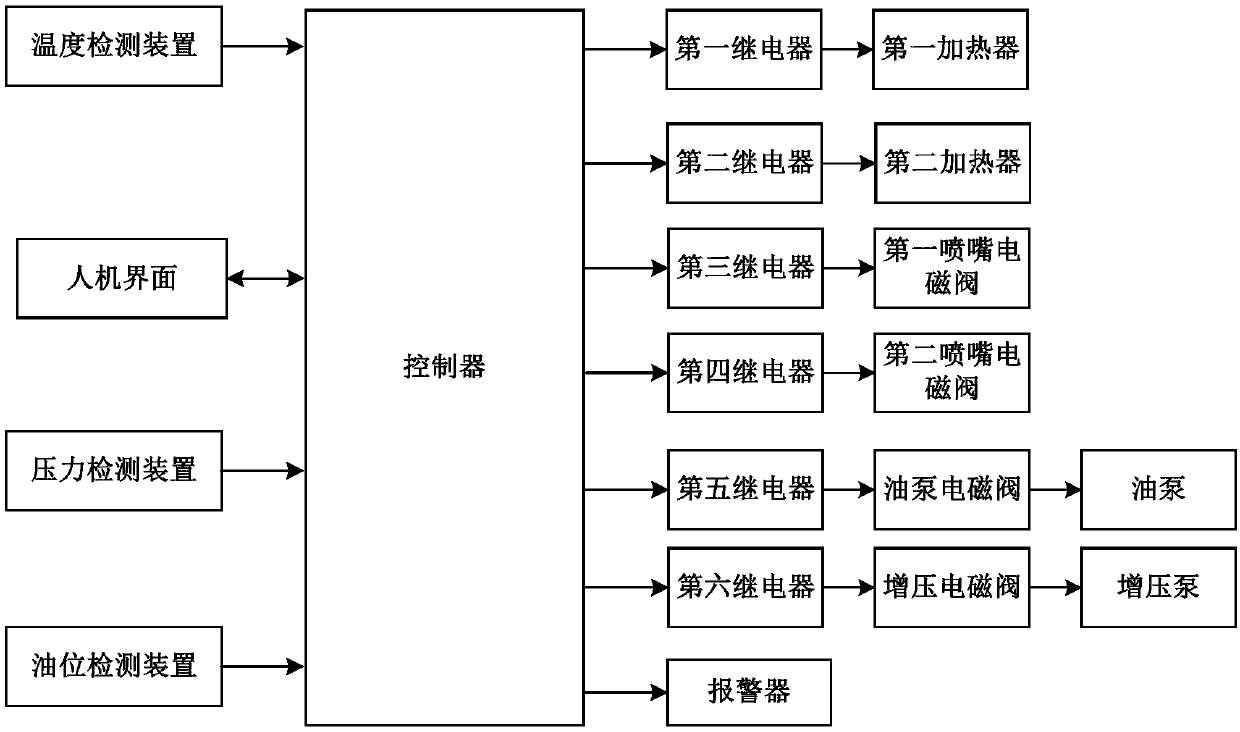

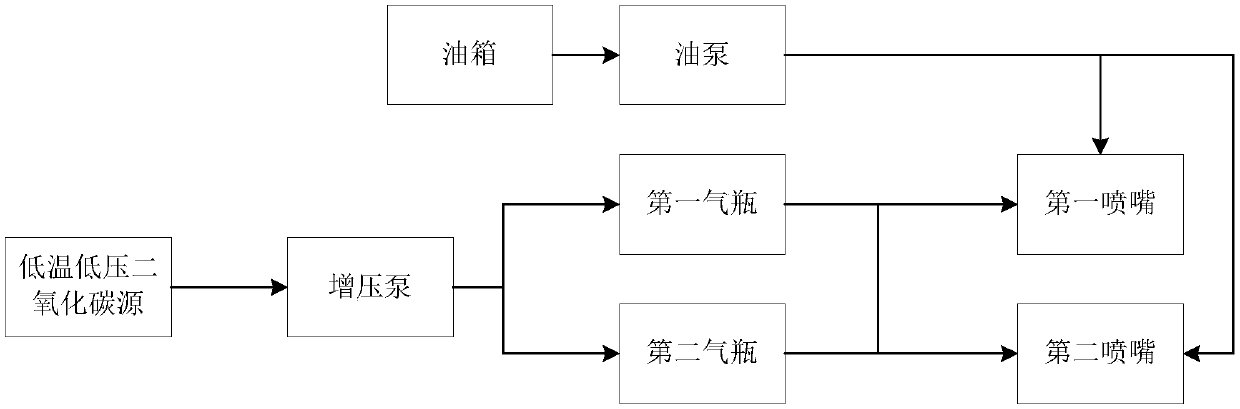

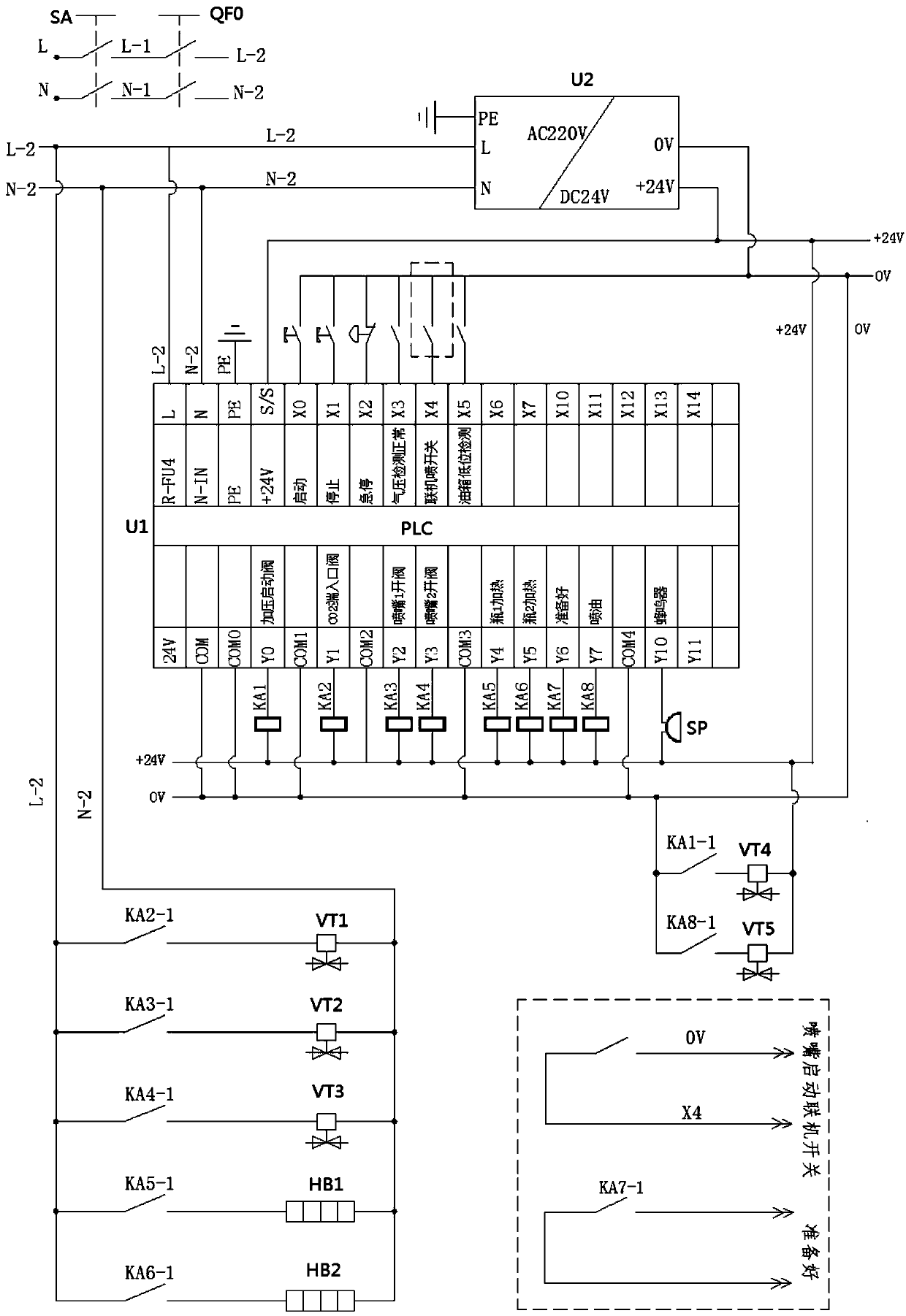

[0037] refer to figure 1 , a supercritical carbon dioxide cooling system comprising:

[0038] a temperature detection device for detecting the temperature of the carbon dioxide inlet, the first gas cylinder and the second gas cylinder;

[0039] a pressure detection device for detecting the pressure of the carbon dioxide inlet, the first gas cylinder and the second gas cylinder;

[0040] Oil level detection device, used to detect the amount of oil in the tank;

[0041] The controller is used to trigger a control signal according to the temperature detected by the temperature detection device, the pressure detected by the pressure detection device, and the oil quantity detected by the oil level detection device to realize automatic control. The control signal includes a boost control signal, a heating temperature rise control signal, oil output control signal and nozzle opening control signal;

[0042] An action execution structure, configured to execute corresponding actions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com