Pre-lithiation device and method for lithium ion battery negative electrode pole piece with controllable pre-lithiation degree

A lithium-ion battery and negative pole piece technology, which is applied in battery electrodes, secondary batteries, secondary battery charging/discharging, etc., can solve the problems of low safety and uncontrollable degree, and achieve high safety and good uniformity , the effect of preventing short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

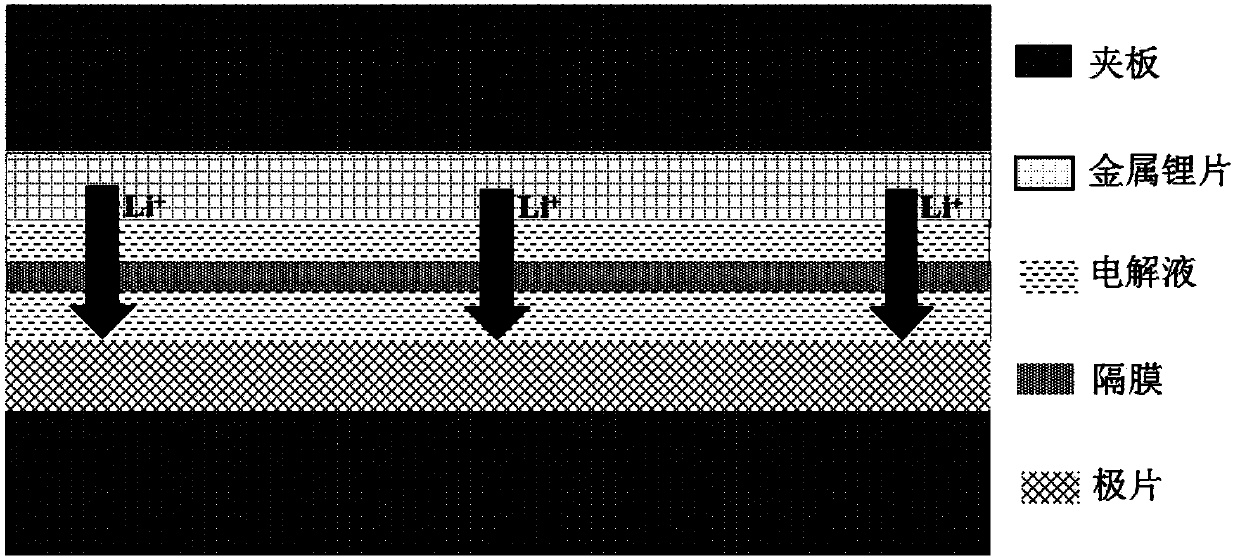

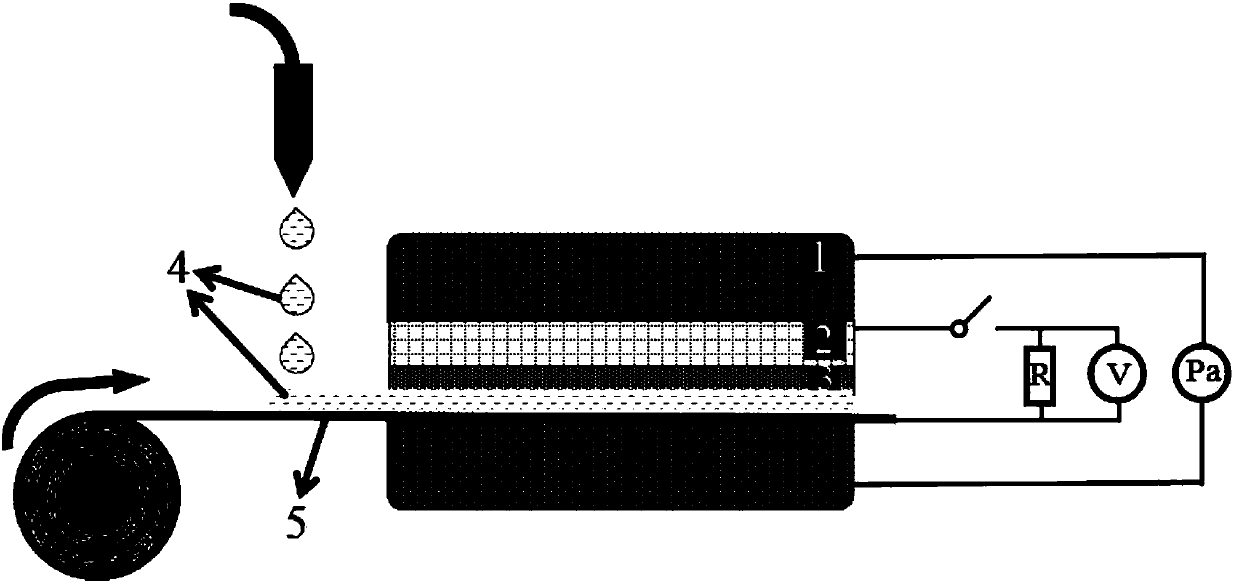

[0041] In a nitrogen atmosphere, place a piece of pure silicon pole piece on a clean splint, add 200 μl of electrolyte dropwise, place the diaphragm on the pole piece, and add 200 μl of electrolyte on it, and place the pole piece 1 mm wider than the pole piece on all sides. The lithium metal sheet is placed on the diaphragm, and another clean splint is placed on the lithium metal sheet. Lead two wires from the pole piece and metal lithium piece respectively, form a closed circuit with a resistor and a switch with a resistance value of 300Ω, and connect a voltmeter to monitor the voltage between the two pole pieces. Turn on the switch, remove the pole piece after pre-lithiation for 5 hours to complete the pre-lithiation operation, so that the pre-lithiation amount in pure silicon is 30% of the total capacity of the negative pole piece.

Embodiment 2

[0043] In an argon atmosphere, place a pure SiO pole piece on a clean splint, add 200 μl of electrolyte dropwise, place the diaphragm on the pole piece, and drop 200 μl of electrolyte on it, making the surrounding area 3mm wider than the pole piece. The metal lithium sheet is placed on the diaphragm, and another clean splint is placed on the metal lithium sheet. Lead two wires from the pole piece and metal lithium piece respectively, form a closed circuit with a resistor and a switch with a resistance value of 100Ω, and connect a voltmeter to monitor the voltage between the two pole pieces. Turn on the switch, remove the pole piece after pre-lithiation for 2 hours to complete the pre-lithiation operation, so that the pre-lithiation amount in pure SiO is 45% of the total capacity of the negative pole piece.

Embodiment 3

[0045] Place a piece of pure SiO on a clean plywood in an argon atmosphere 2 For the pole piece, add 200 μl of electrolyte dropwise, place the diaphragm on the pole piece, and add 200 μl of electrolyte dropwise on it, place a lithium metal sheet with a width of 2 mm on all sides than the pole piece on the diaphragm, and place another clean splint on the pole piece. on the lithium metal sheet. Lead two wires from the pole piece and the lithium metal piece respectively, form a closed circuit with a resistor and a switch with a resistance value of 1000Ω, and connect a voltmeter to monitor the voltage between the two pole pieces. Turn on the switch, remove the pole piece after pre-lithiation for 24 hours to complete the pre-lithiation operation, so that pure SiO 2 The amount of pre-lithiation is 70% of the total capacity of the negative electrode sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com