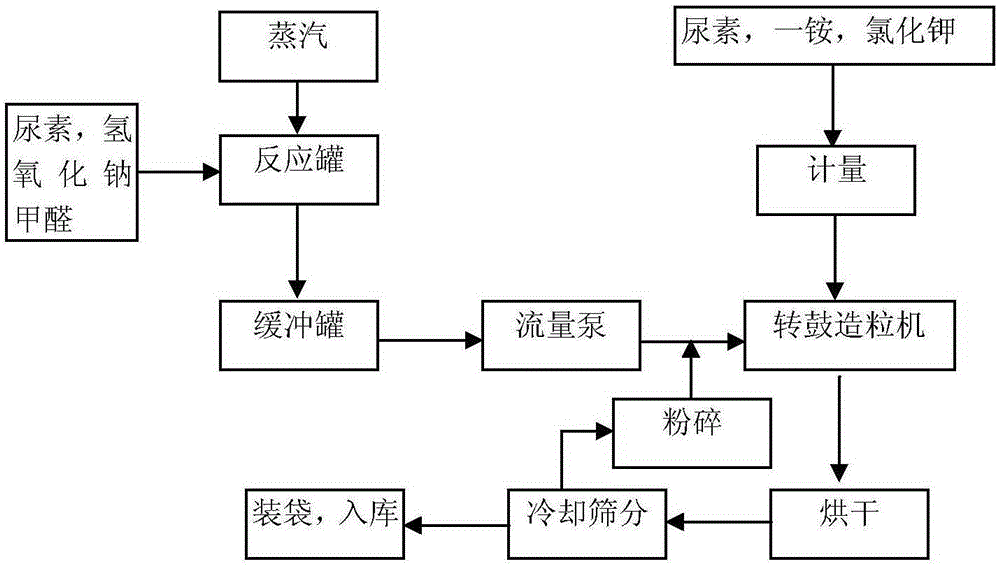

Device and method for improving urea formaldehyde compound fertilizer on amino acid compound fertilizer production line

A technology of urea-formaldehyde and compound fertilizer, which is applied in the direction of fertilization device, fertilizer mixture, sustainable manufacturing/processing, etc., can solve the problems that have not been developed, and achieve the effects of reducing the frequency of fertilization, saving energy, and high pelleting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

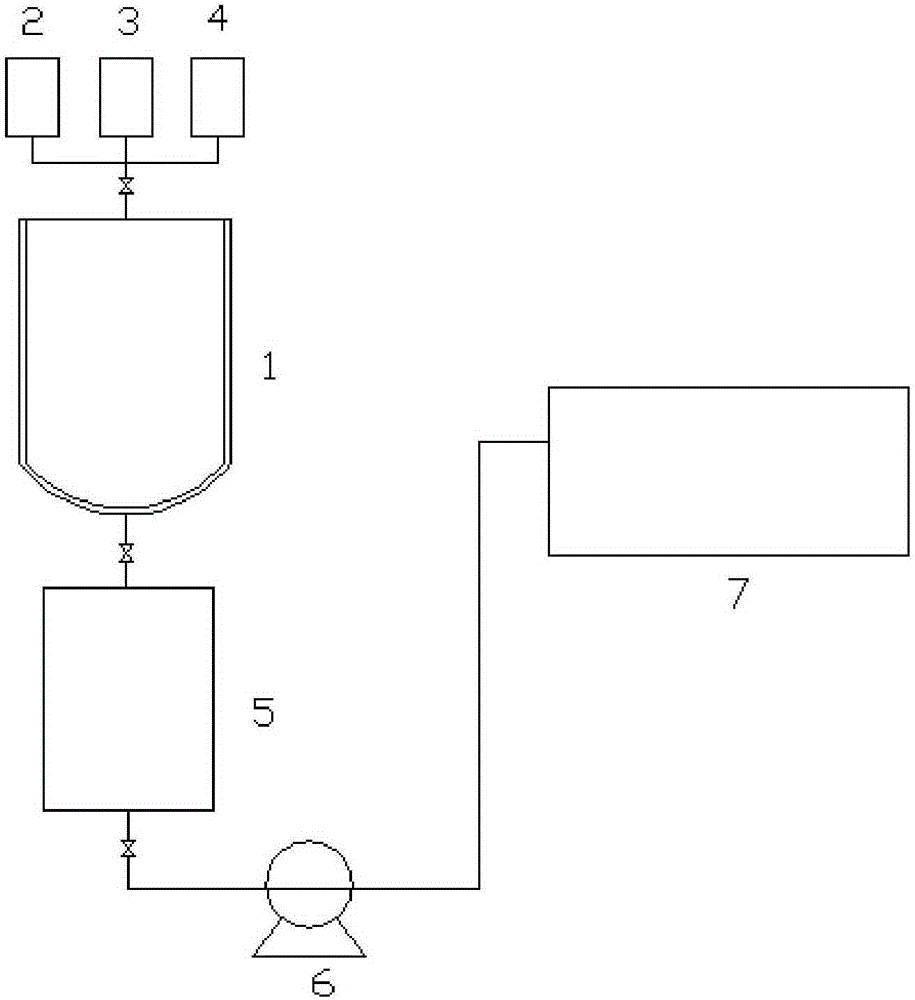

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the present invention. within the scope of protection.

[0031] The following methods are conventional methods unless otherwise specified.

[0032] The following percentages (%) are mass percentages unless otherwise specified.

[0033] 1. Raw materials

[0034] Urea (crushed before use), formaldehyde 37% aqueous solution, 20-40% potassium hydroxide solution, solid ammonium chloride or ammonium chloride saturated solution.

[0035] 2, the method for rapidly preparing urea-formaldehyde in strong acid medium

[0036] Specific steps: In a 5000L urea-formaldehyde reaction tank equipped with an electric stirrer,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com