Single-station semi-automatic dynamic balance adjusting device

An adjustment device and semi-automatic technology, applied in the mechanical field, can solve problems such as rotor imbalance, safety accidents, wear, etc., and achieve the effects of reducing eccentricity, improving accuracy, and avoiding positioning deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

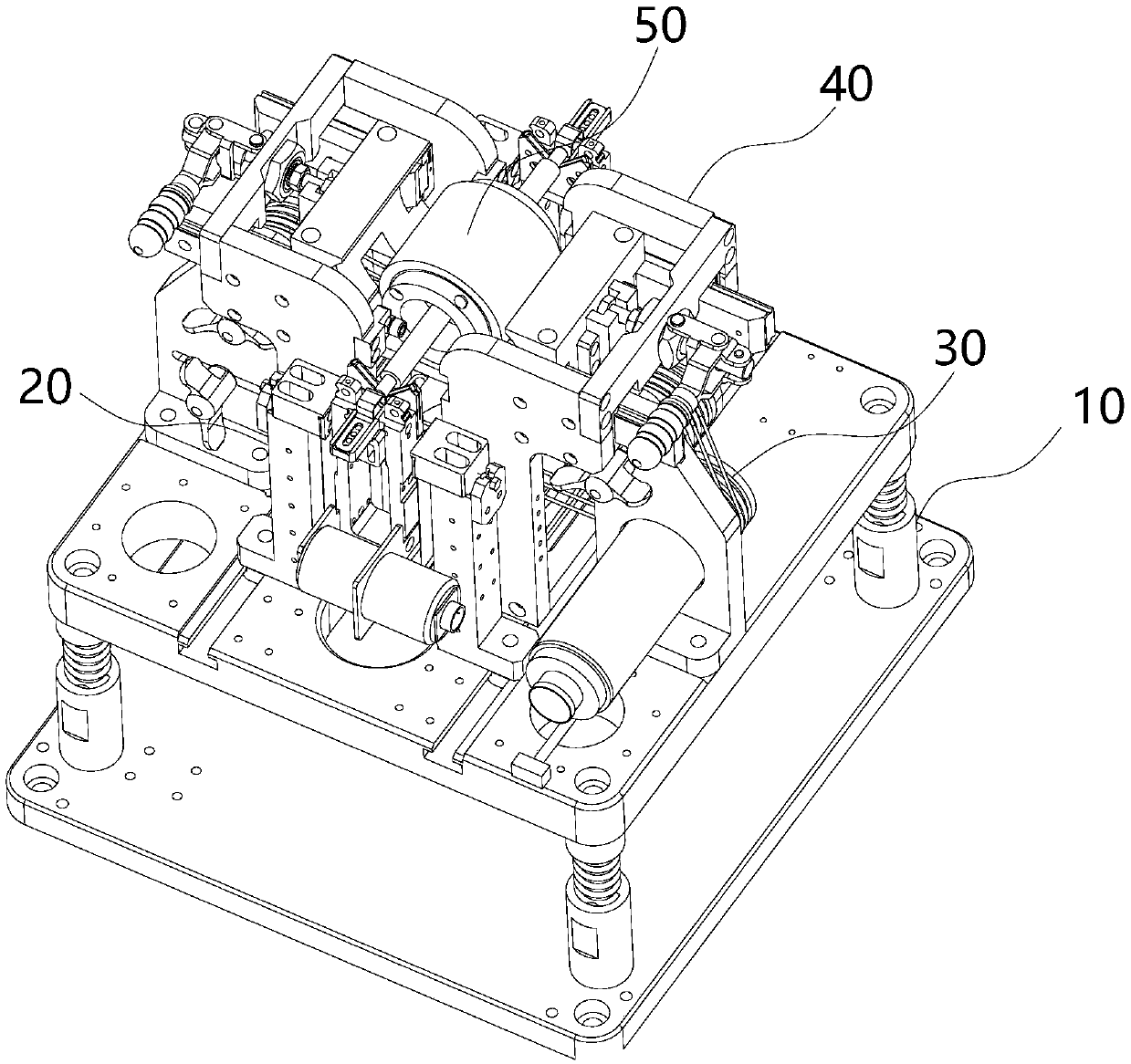

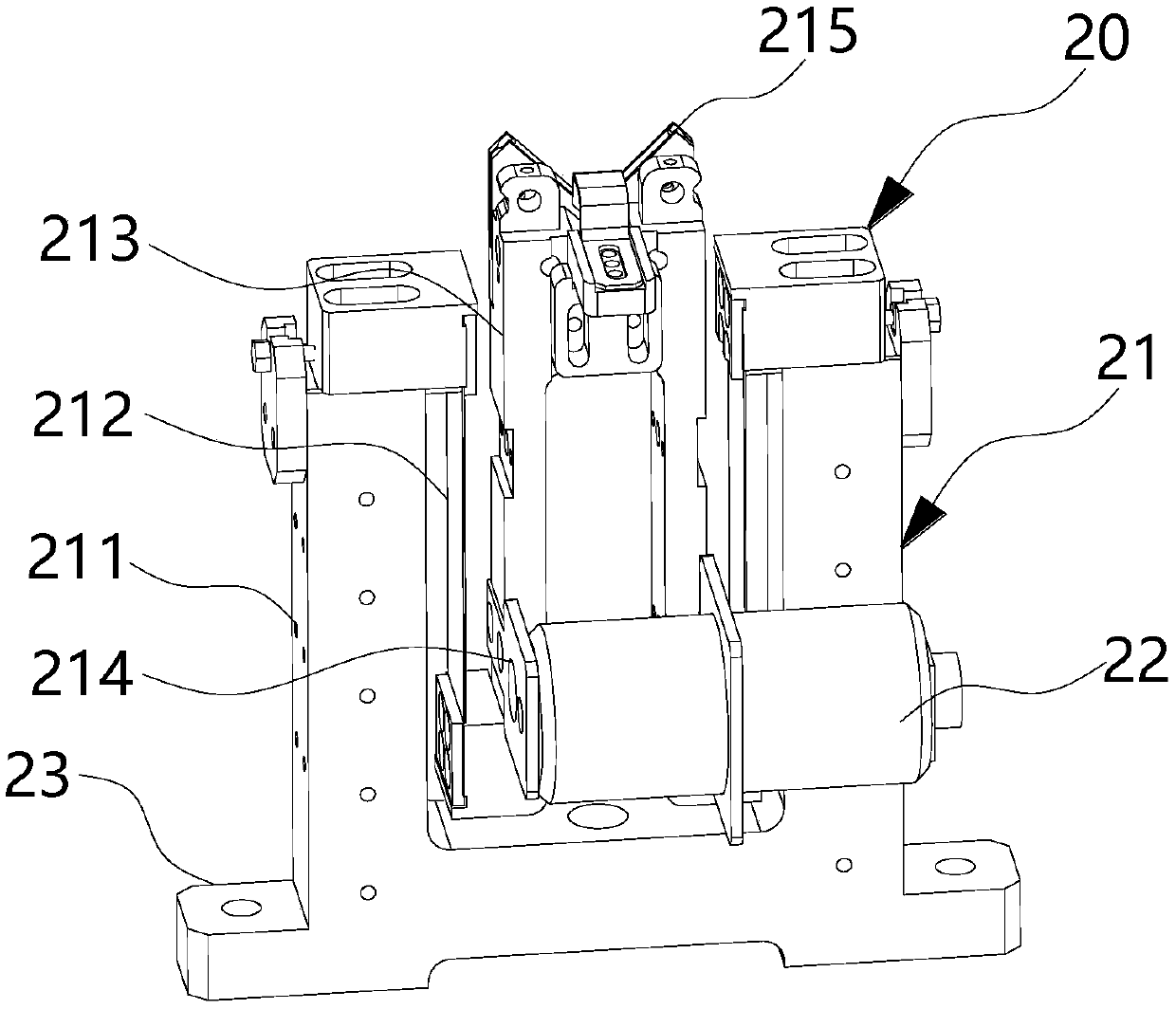

[0029] like Figure 1~6 As shown, one embodiment of the present invention discloses a single-station semi-automatic dynamic balance adjustment device, which generally includes: an elastic shock-absorbing seat 10 for eliminating external vibration interference, and an elastic shock-absorbing seat 10 installed on the elastic shock-absorbing seat 10 for supporting The supporting assembly 20 of the dynamically balanced rotor 50 to be tested, the driving assembly 30 for driving the rotor 50 to rotate, the rotor clamp 40 for clamping and fixing the rotor 50 for dynamic balance adjustment, and the control module for controlling the measurement process of the rotor 50 .

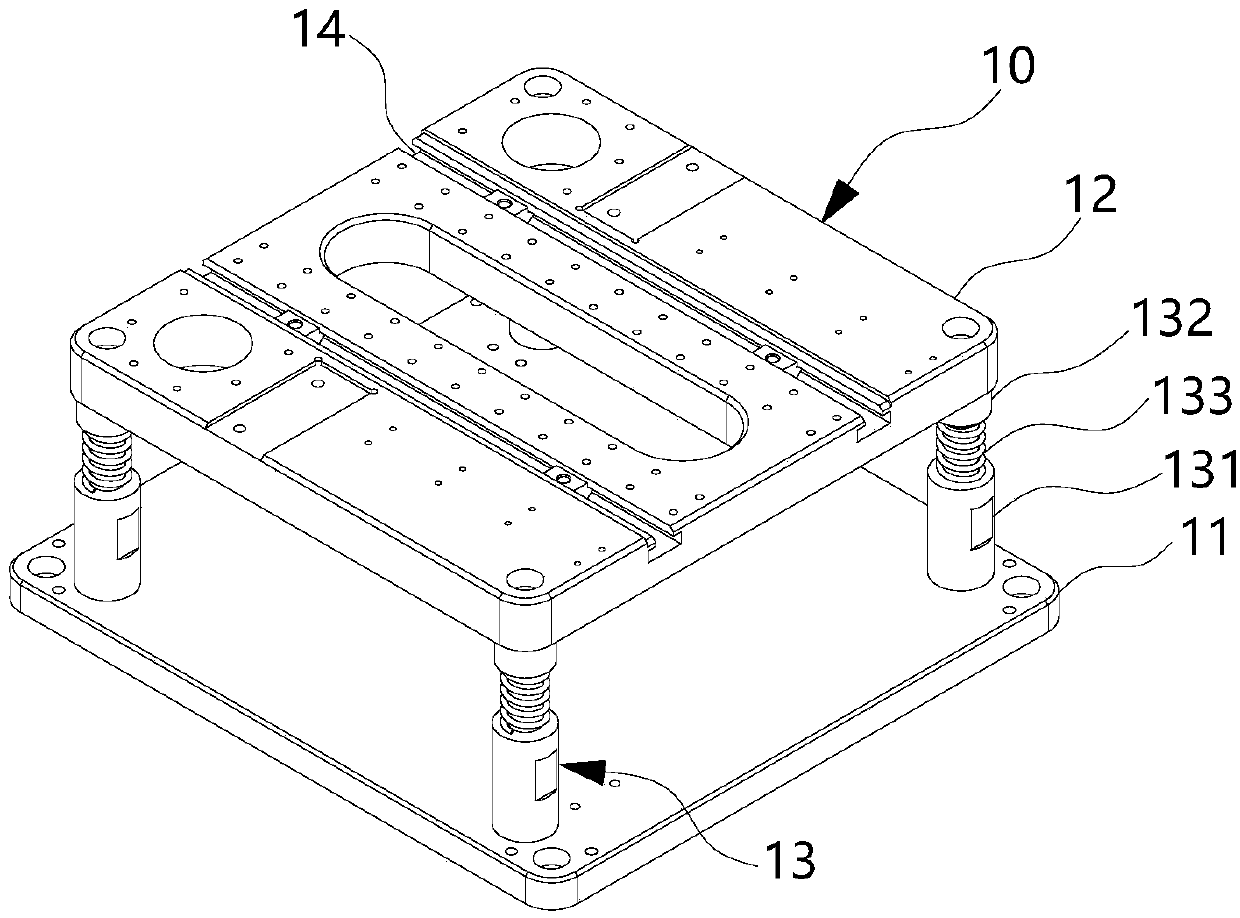

[0030] The elastic shock absorber 10 includes two fixed platforms 11 and 12 installed by superposing elastic parts 13. The fixed platforms 11 and 12 can reduce or eliminate the vibration of the ground through the elastic parts 13, so as to avoid transmission to the rotor 50 and affect the dynamic balance test effect. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com