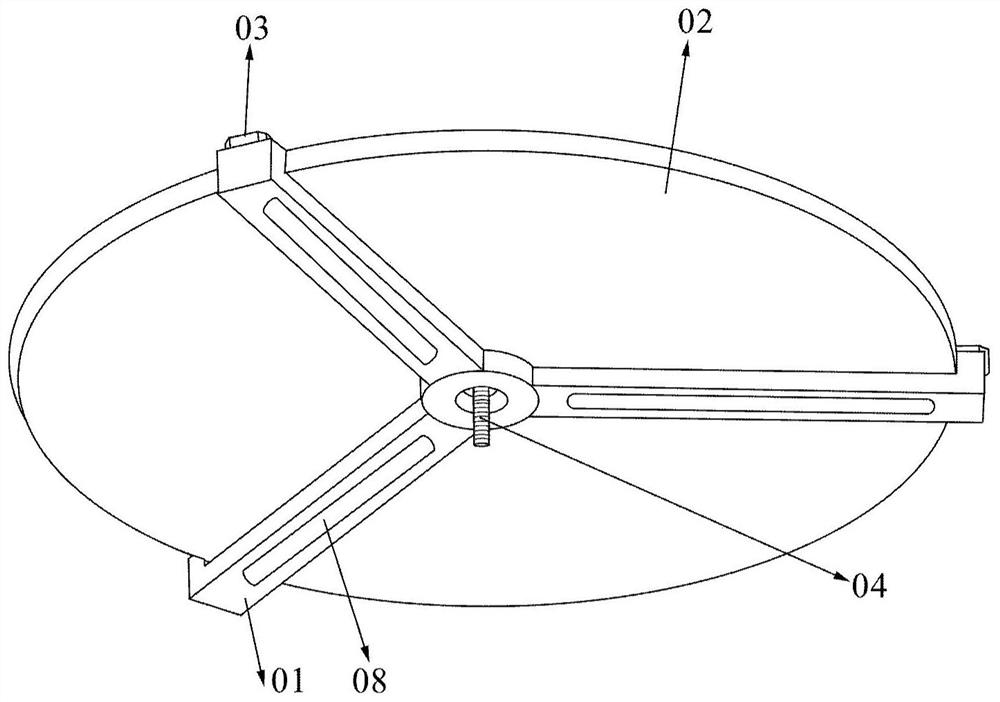

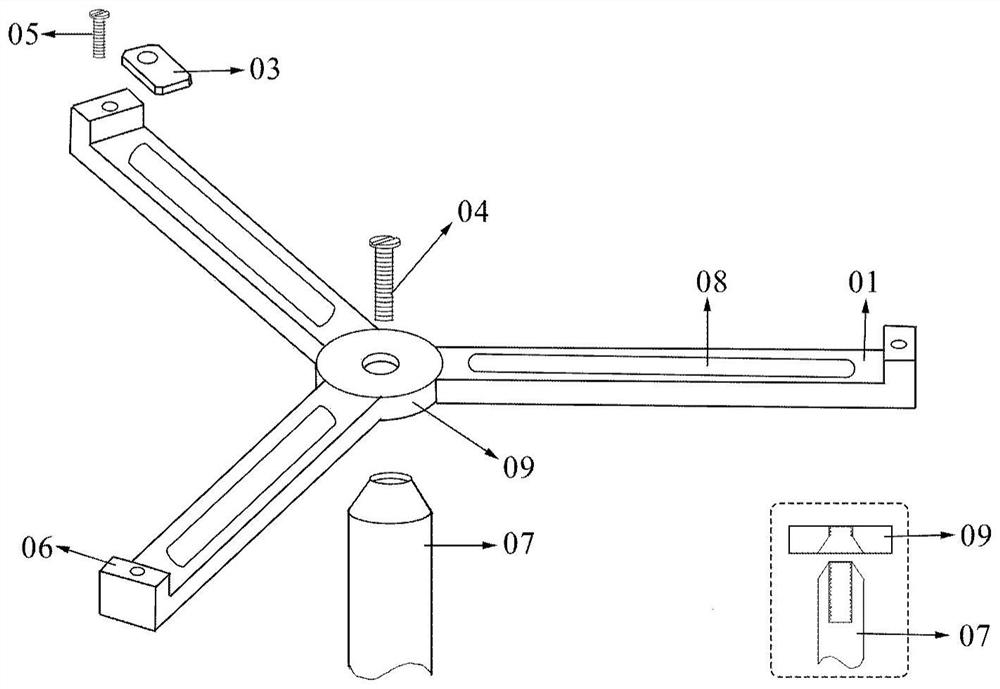

Rotary Tray Fixture

A technology of fixing device and rotating tray, applied in metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of tray tray shaking, substrate chip rupture, tray instability, etc., to reduce weight and achieve stability , the effect of reducing the radiation shielding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to improve the growth quality of thin film materials, it is necessary to improve the temperature uniformity of the tray and the uniform distribution of the gaseous source material on the surface of the tray. Generally, a motor is installed outside the reaction chamber, and the tray connected to the reaction chamber by the rotating shaft drives the tray to rotate at a low or high speed. Rotation brings problems such as airflow vortices, which will cause the tray to be affected by the airflow and become unstable. In the case of high-speed rotation, if the tray is not stable, it is easy to cause the tray to overturn, causing dangers such as rupture of the substrate and even damage to the reaction chamber.

[0032] As the heated body, the tray is currently heated by direct current radiation or alternating current induction. Radiation heating is divided into resistance wire heating and resistance sheet heating. Applying direct current to the resistance wire or resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com