Probiotic fresh milk and preparation method thereof

A technology of probiotics and probiotics powder, which is applied in the directions of milk preparations, bacteria and dairy products used in food preparation, can solve the problems of restricting the intake of probiotics, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

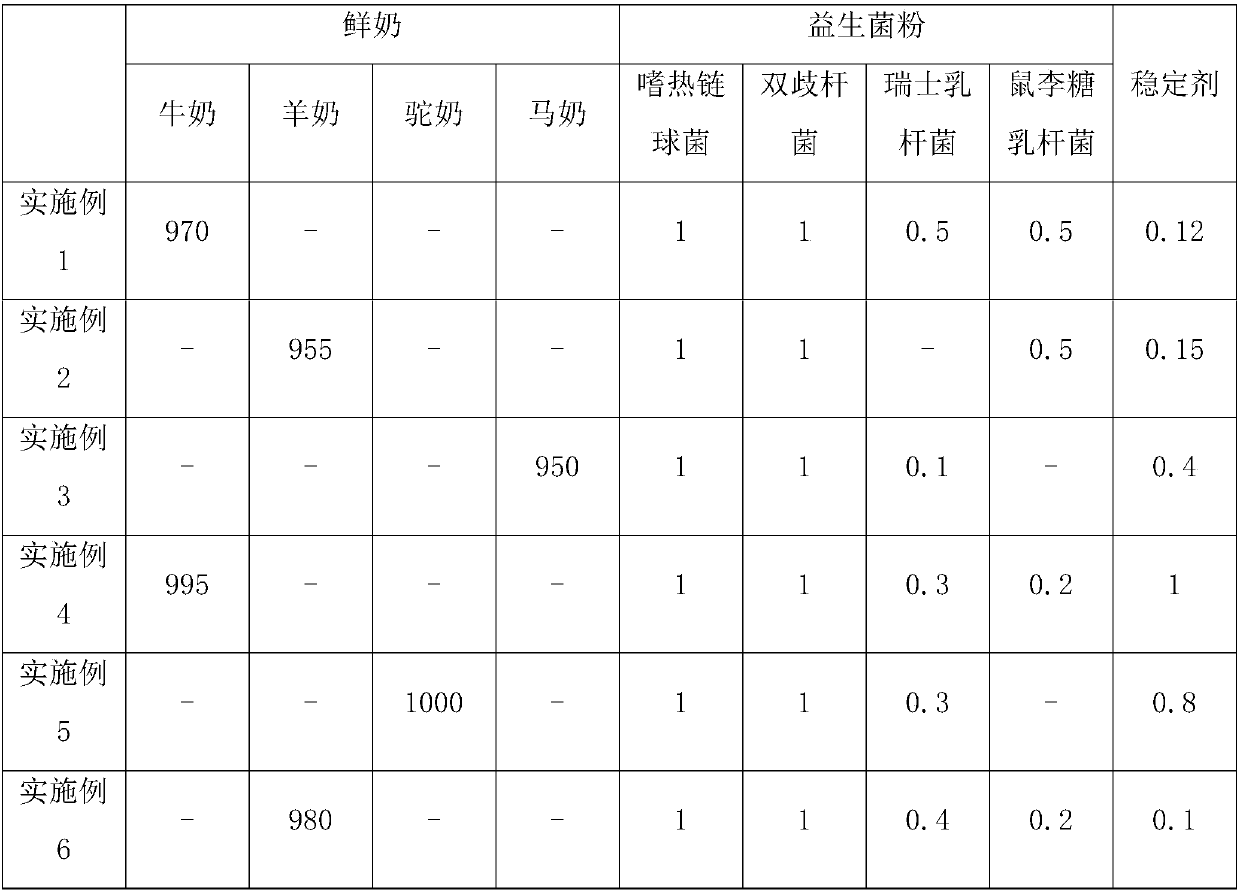

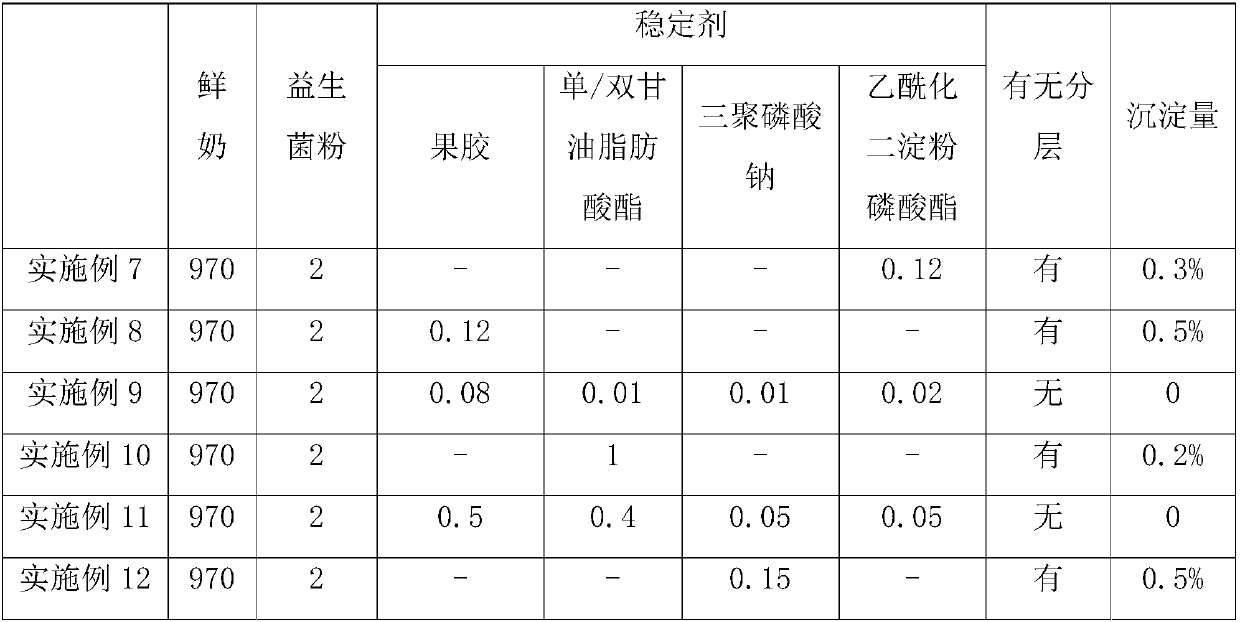

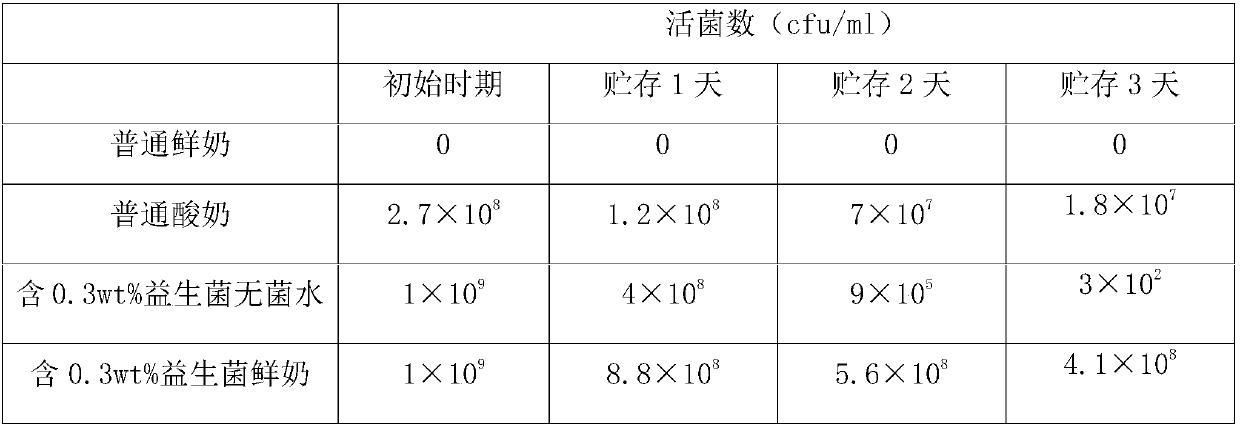

Examples

Embodiment 1

[0054] 1. Heat 500g of fresh milk through a plate heat exchanger to 55°C and pour it into the emulsification tank;

[0055] 2. Shear emulsify the stabilizer and the material in the previous step at 2000r / min for 5min;

[0056] 3. Cool the material in the previous step to 10°C, pump it to the batching tank, and add 450g of fresh milk to quantify it, and use a plate heat exchanger to cool the material in step S2;

[0057] 4. Homogenize the materials in the previous step by 19Mpa;

[0058] 5. The material in the previous step is sterilized at 85°C for 15 seconds, and cooled down to 10°C through the plate and put into the high-level tank;

[0059] 6. Set the number of viable bacteria to 10 11 The cfu / g probiotic powder is first dissolved in 20g fresh milk at 40°C, then added to the material in the previous step and stirred for 5 minutes;

[0060]7. Carry out aseptic filling of the materials in the previous step to obtain finished products, among which, aseptic filling is carrie...

Embodiment 2

[0063] 1. Heat 550g of fresh milk through a plate heat exchanger to 50°C and pour it into the emulsification tank;

[0064] 2. Shear and emulsify the stabilizer and the material in the previous step at 2200r / min for 10min;

[0065] 3. Cool the material in the previous step to 15°C, pump it to the batching tank, and add 365g of fresh milk to quantify it, and use a plate heat exchanger to cool the material in step S2;

[0066] 4. Homogenize the material in the previous step at 22Mpa;

[0067] 5. The material in the previous step is sterilized at 80°C for 10 seconds, and cooled down to 5°C by the plate and put into the high-level tank;

[0068] 6. Set the number of viable bacteria to 5×10 11 The cfu / g probiotic powder is first dissolved in 40g fresh milk at 40°C, then added to the previous step and stirred for 5 minutes;

[0069] 7. Carry out aseptic filling of the materials in the previous step to obtain finished products, among which, aseptic filling is carried out through t...

Embodiment 3

[0072] 1. Heat 500g of fresh milk through a plate heat exchanger to 52°C and pour it into the emulsification tank;

[0073] 2. Shear emulsify the stabilizer and the material in the previous step at 2400r / min for 8min;

[0074] 3. Cool the material in the previous step to 12°C, pump it to the batching tank, and add 420g of fresh milk quantitatively, wherein a plate heat exchanger is used to cool the material in step S2;

[0075] 4. Homogenize the material in the previous step by 20Mpa;

[0076] 5. The material in the previous step is sterilized at 85°C for 10 seconds, and cooled down to 8°C through the plate and put into the high-level tank;

[0077] 6. Set the number of viable bacteria to 8×10 11 The cfu / g probiotic powder is first dissolved in 30g fresh milk at 40°C, then added to the material in the previous step and stirred for 4 minutes;

[0078] 7. Carry out aseptic filling of the materials in the previous step to obtain finished products, among which, aseptic filling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com