Inverted pickup type special double-tool milling machine

An inverted, cutting tool technology, which is applied in the direction of milling machine equipment, milling machine equipment details, manufacturing tools, etc., can solve the problems of low processing efficiency and cumbersome operation, and achieve the effect of saving space, high integration and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

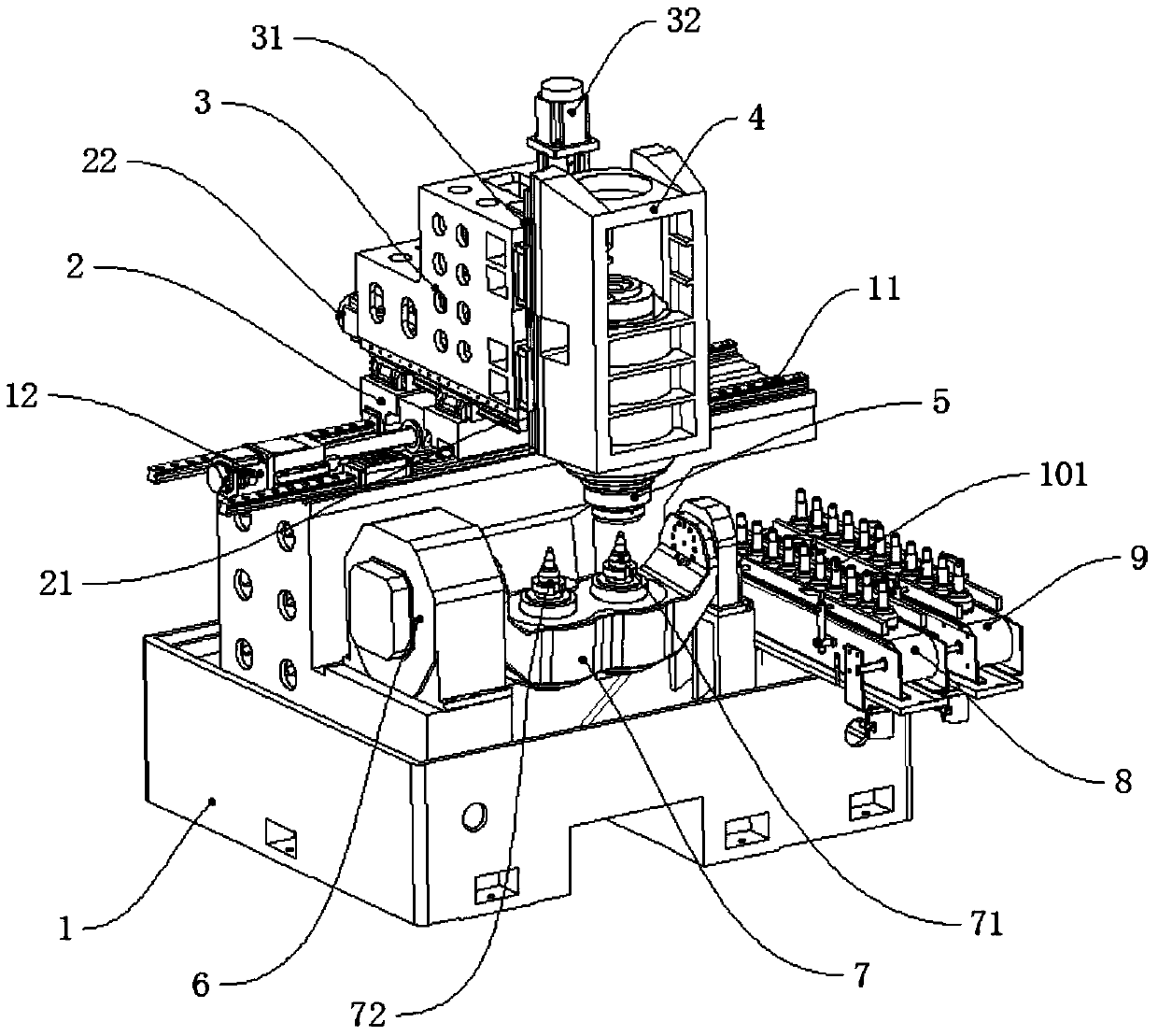

[0013] Such as figure 1 Shown: an inverted pick-up special double-tool milling machine, including a bed 1, a slide seat 2, a saddle 3, a slide table 4, a pick-up spindle 5, a rotary drive 6, a swing table 7, a feeding conveyor belt 8 and The blanking conveyor belt 9, the slide seat 2 is installed on the Z-axis linear guide rail 11 of the bed 1 and driven by the Z-axis motor 12 screw rod on the bed 1, and the slide saddle 3 is installed on the Y-axis of the slide seat 2 axis linear guide 21 and driven by the Y-axis motor 22 screw on the slide 2, the slide 4 is installed on the X-axis linear guide 31 of the saddle 3 and driven by the X-axis motor 32 screw on the saddle 3 Drive, the pick-up spindle 5 is installed on the sliding table 4, the pick-up spindle 5 adopts a high-speed torque type electric spindle, and a hydraulic clamp is installed at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com