Manufacturing method of non-uniform crankle box girder rotary ladder

A manufacturing method and technology of box girders, which are applied in the field of manufacturing uneven curved and twisted box girder rotary ladders, can solve the problems of long construction period, complicated manufacturing process, high control precision requirements, etc., and achieve good forming effect and high dimensional accuracy , Improve the effect of production accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

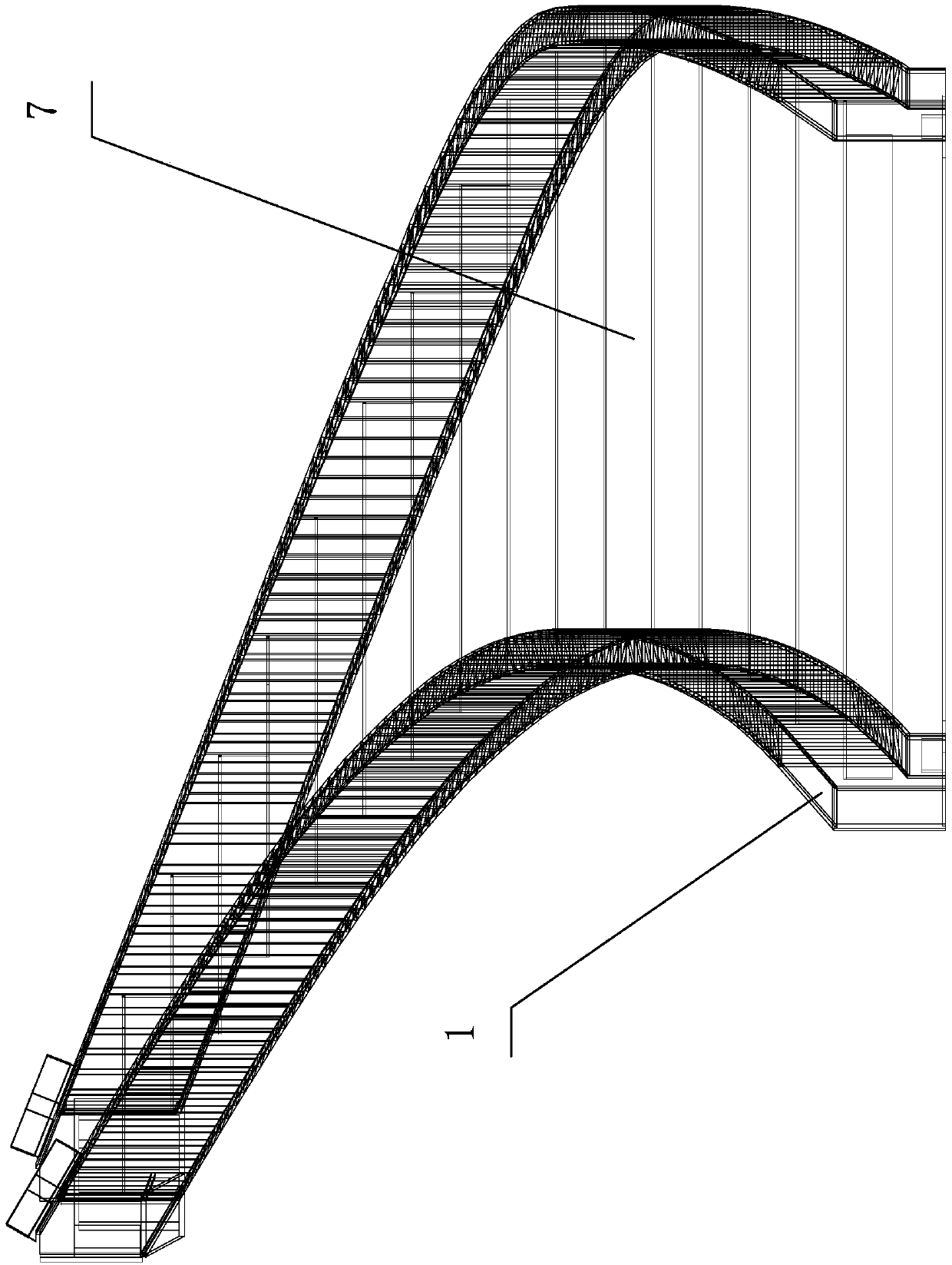

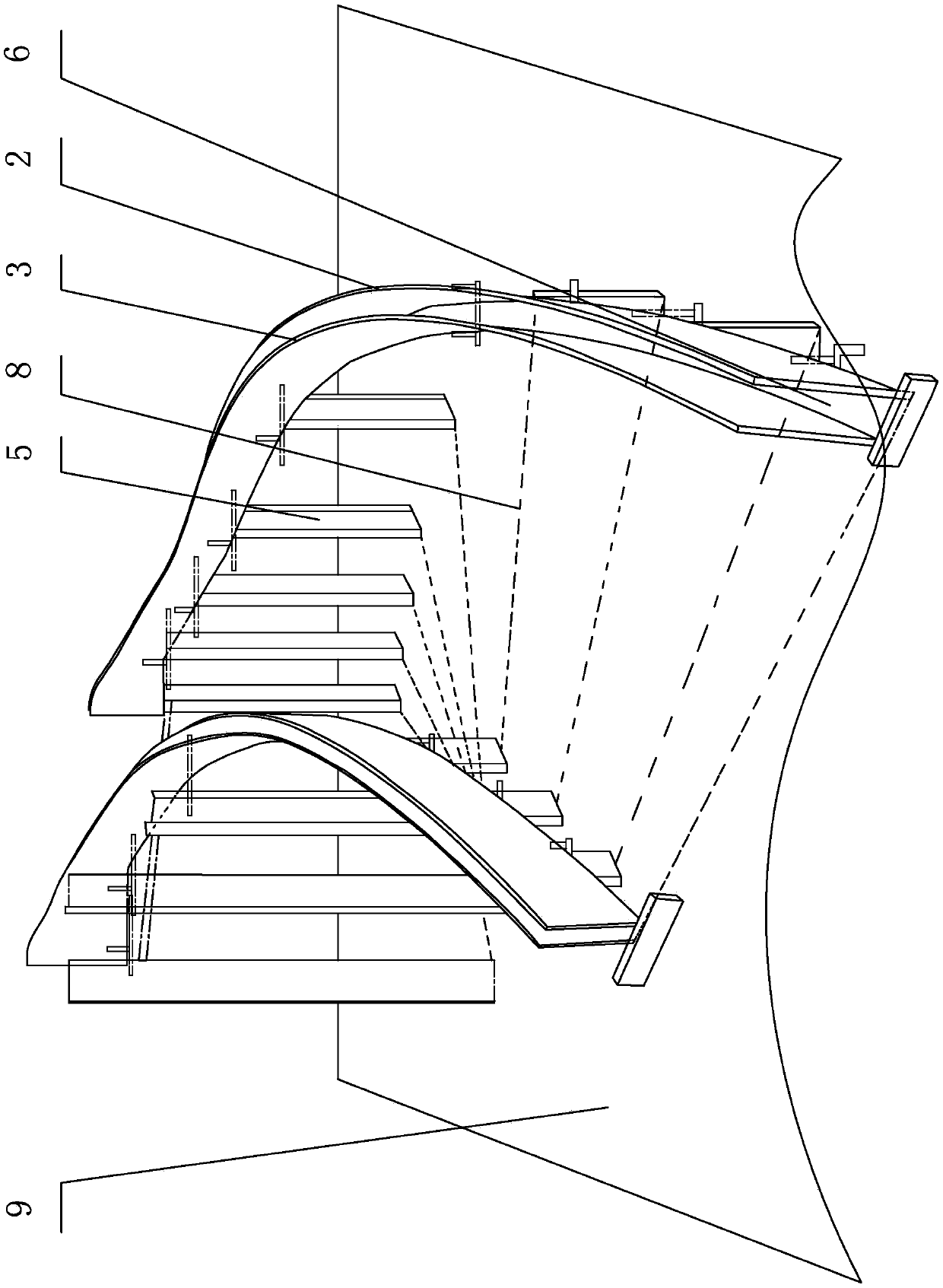

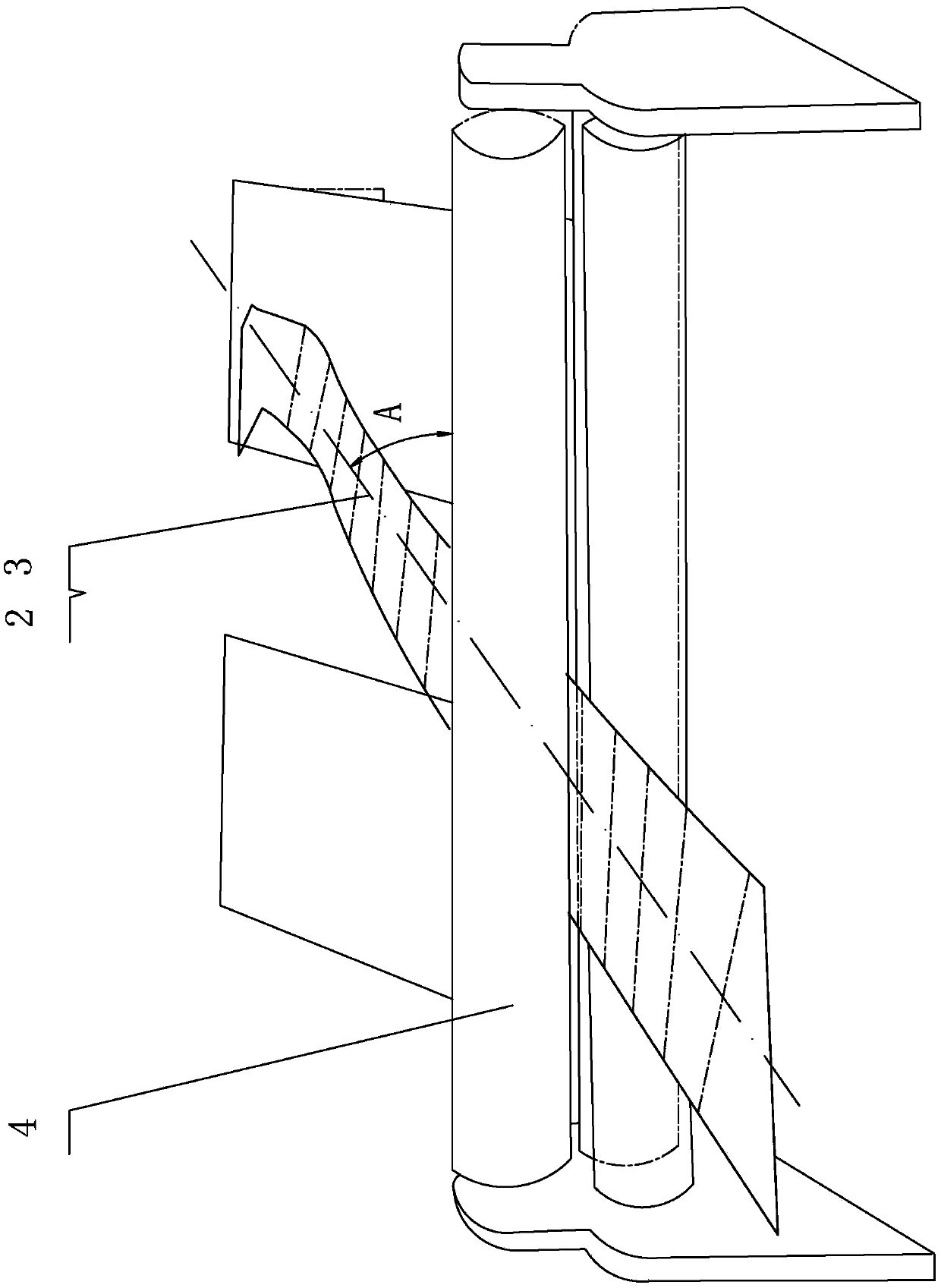

[0025] The present invention relates to the manufacture method of the uneven bending and torsion box girder rotating ladder, the structure of the uneven bending and twisting box girder rotating ladder is as follows figure 1 As shown, its structure includes left and right twisted box beams 1 that rotate upwards and multi-stage stair steps 7 arranged between the left and right twisted box beams 1. Each twisted box beam 1 includes upper and lower The top plate and bottom plate 6 and the inner and outer webs 3 and flange plates 2, all levels of stair steps 7 are boards that are folded into approximately 90°.

[0026] The manufacturing method of the uneven bending and torsion box girder revolving ladder of the present invention, its parts processing and on-site construction scheme are as follows:

[0027] 1. According to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com