Composite micro-texture guide rail and preparation method thereof

A technology of micro-texture and guide rail, which is applied in the direction of grinding slide plate, grinding frame, grinding bed, etc., can solve the problem of large gap of micro-porous texture, inability to fully exert the function of texture to collect wear debris, and insufficient lubrication Sufficient and other issues, to achieve low friction coefficient, reduce friction coefficient, improve the effect of bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

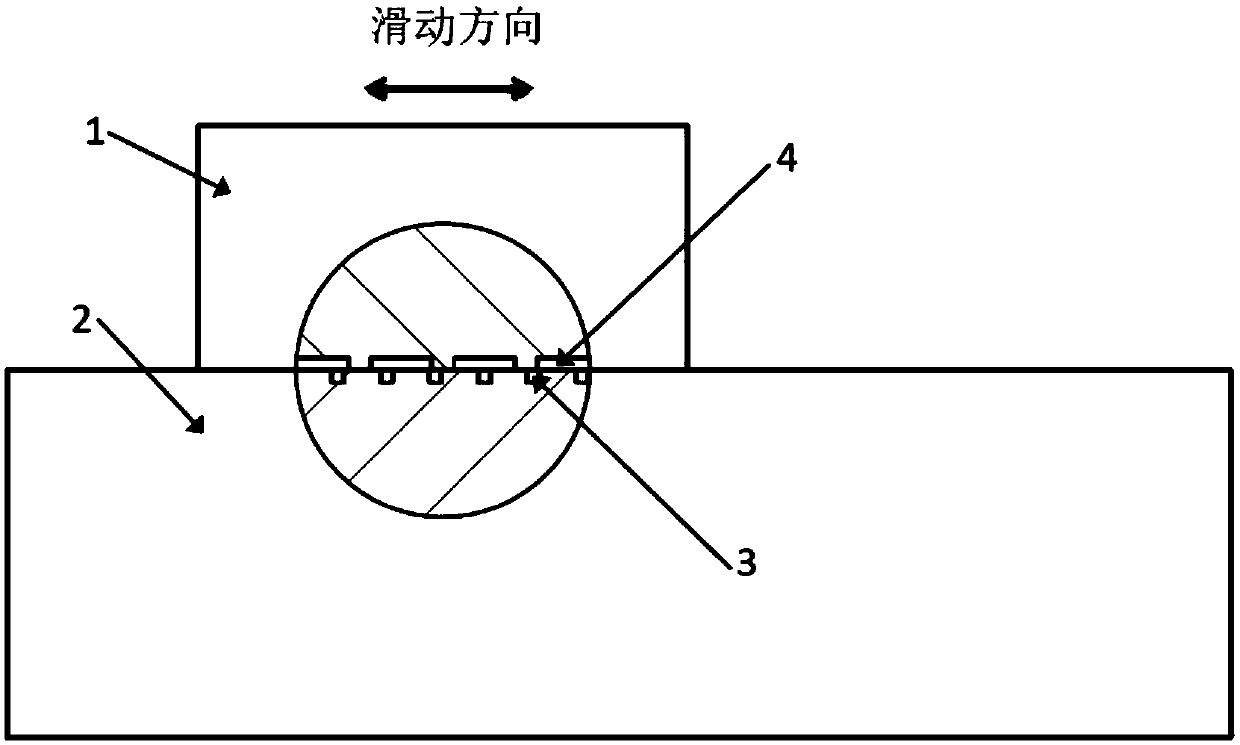

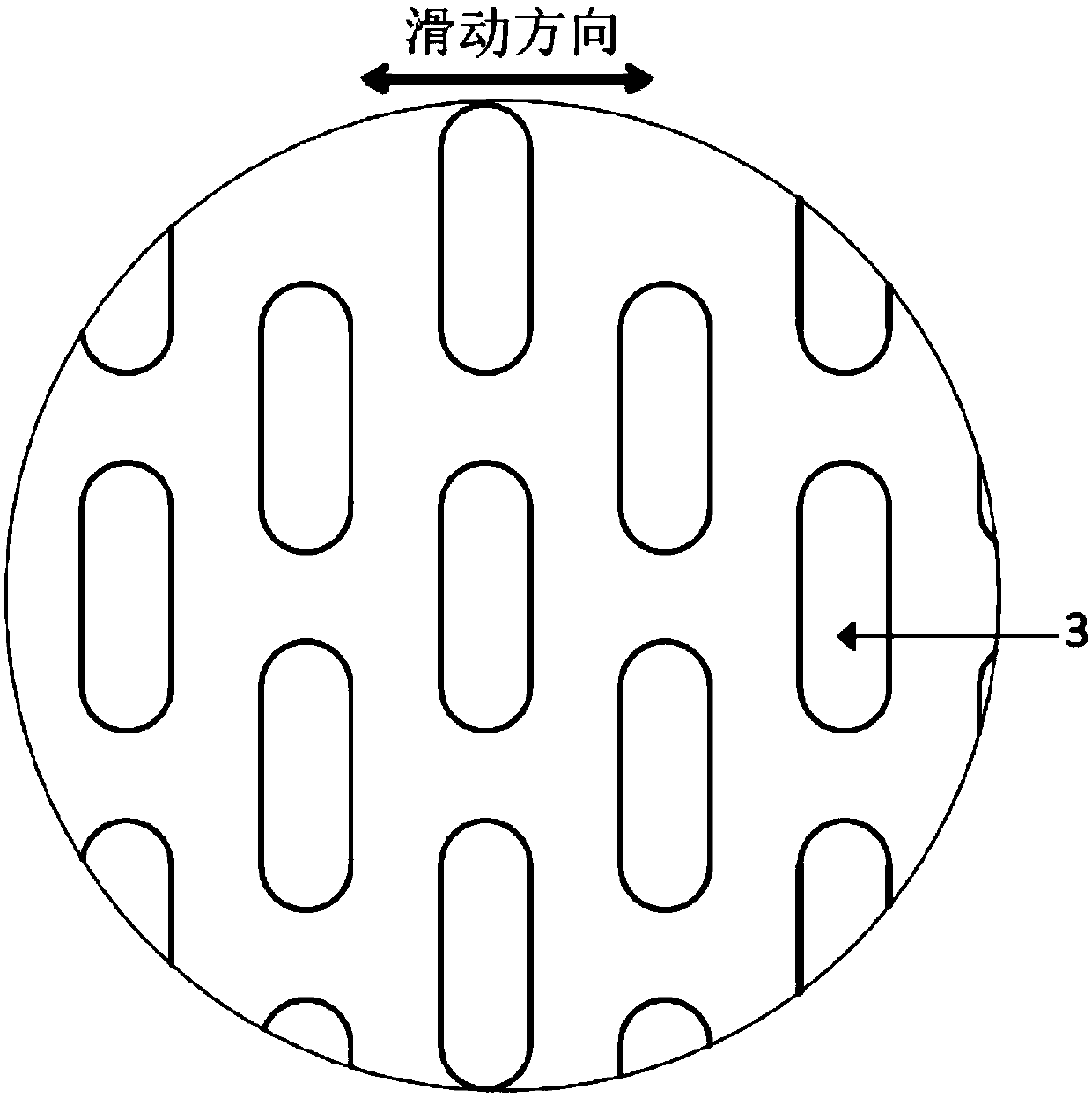

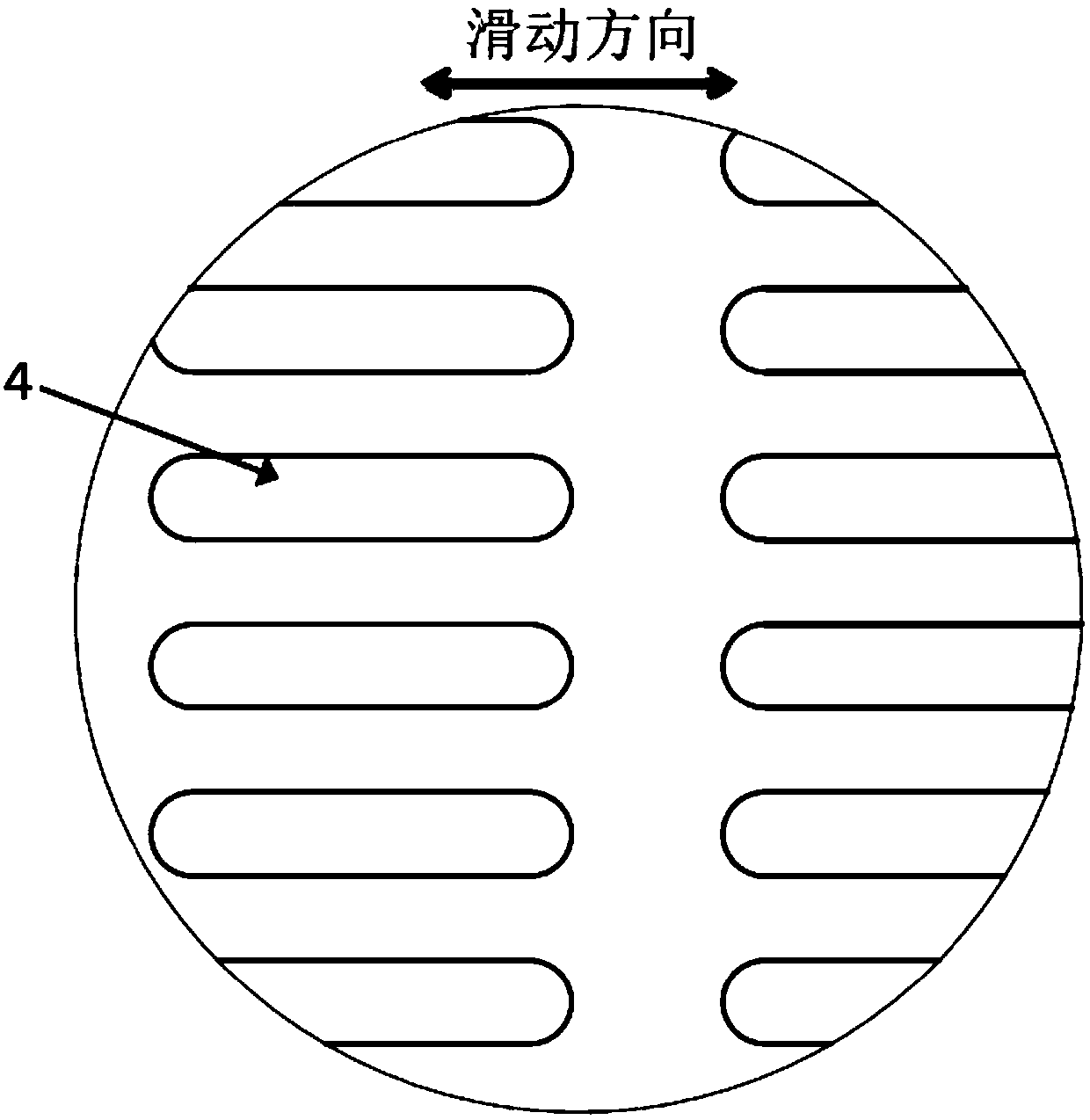

[0045]The material of the fixed guide rail 1 is HT300 gray cast iron, and the arithmetic average deviation of the surface roughness profile achieved after grinding is Ra≤0.4μm; the laser is used to process micron-scale textured grooves perpendicular to the sliding direction on the upper surface of the fixed guide rail 1, The micro-textured groove includes the first section, the second section and the third section. The first section and the third section are semicircular grooves, the second section is a rectangular groove, and the second section is located between the first section and the second section. between the segments, and the diameters of the semicircular grooves of the first and third segments coincide with the short sides of the rectangular grooves of the second segment. The width of the textured groove is 50 μm, the spacing in the groove width direction is 200 μm, the length is 1000 μm, the spacing in the longitudinal direction is 1000 μm, and the depth is 50 μm; T...

Embodiment 2

[0048] The material of the fixed guide rail 1 is high-frequency quenched 45 steel, and the arithmetic average deviation of the surface roughness profile achieved after grinding is Ra≤0.4μm. Lasers are used to process micron-scale texture grooves perpendicular to the sliding direction on the surface of the fixed guide rail 1. The micro-textured groove includes the first section, the second section and the third section, the first section and the third section are semicircular grooves, the second section is a rectangular groove, and the second section is located between the first section and the third section. Between the second section, the diameters of the semicircular grooves of the first section and the third section coincide with the short sides of the rectangular grooves of the second section. The width of the textured groove is 30 μm, the spacing in the groove width direction is 100 μm, the length is 200 μm, the spacing in the longitudinal direction is 100 μm, and the dept...

Embodiment 3

[0051] The material of the fixed guide rail 1 is HT300 gray cast iron, and the arithmetic average deviation of the surface roughness profile achieved after grinding is Ra≤0.4μm; the laser is used to process micron-scale textured grooves perpendicular to the sliding direction on the upper surface of the fixed guide rail 1, The micro-textured groove includes the first section, the second section and the third section. The first section and the third section are semicircular grooves, the second section is a rectangular groove, and the second section is located between the first section and the second section. between the segments, and the diameters of the semicircular grooves of the first and third segments coincide with the short sides of the rectangular grooves of the second segment. The width of the textured groove is 10 μm, the spacing in the groove width direction is 20 μm, the length is 200 μm, the spacing in the longitudinal direction is 100 μm, and the depth is 10 μm; The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com