White carbon black compaction device

A compaction device and black compaction technology are applied in the directions of packaging, transportation and packaging, and the type of packaged items. It can solve the problems of increasing production costs, affecting the health of production personnel in the environment, and wasting white carbon black powder. It can alleviate vibration, Convenient packaging and avoiding damage to parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

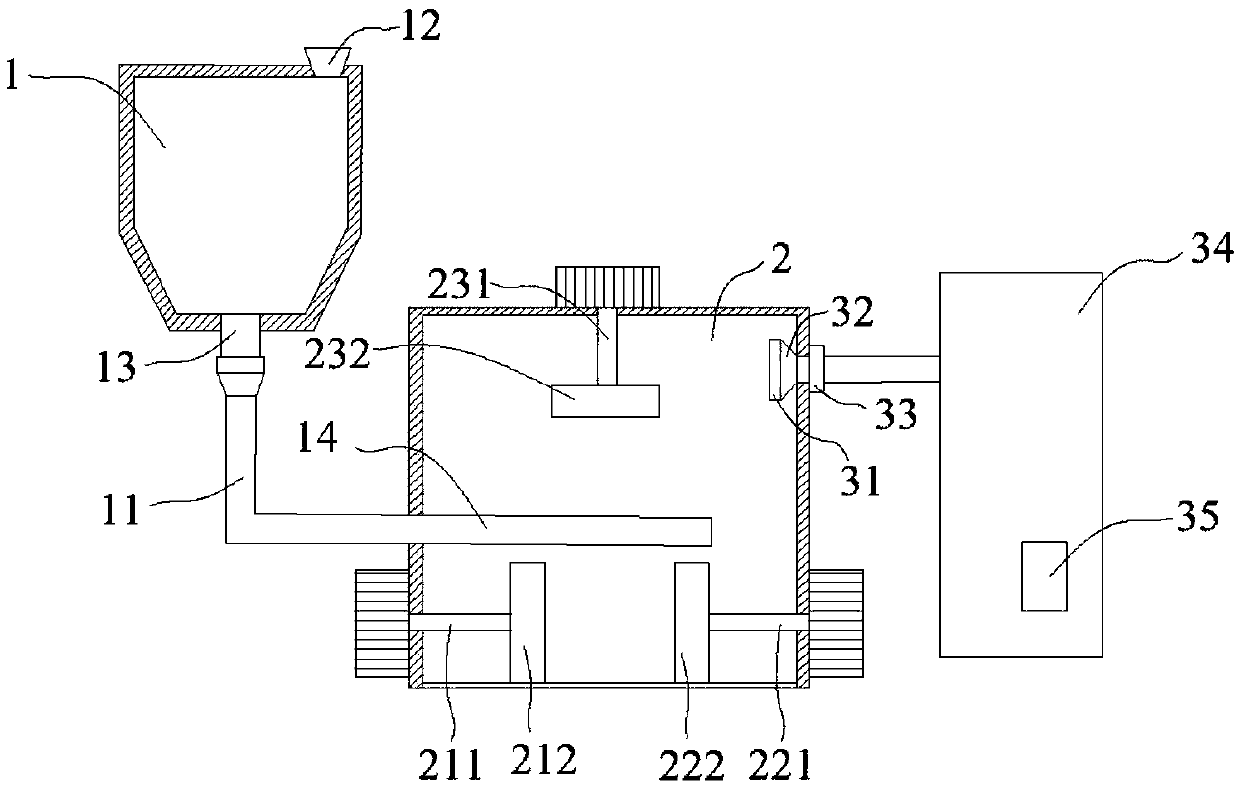

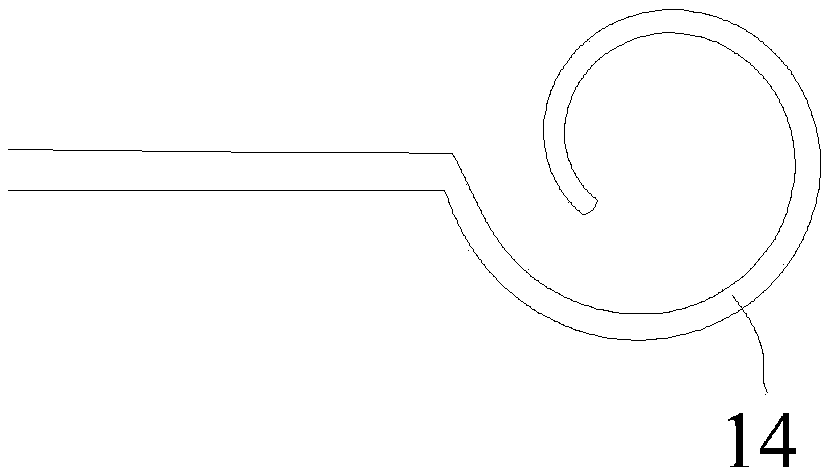

[0043] Such as figure 1 As shown, the silica compaction device includes a storage box 1, a compaction box 2, and a dust collection device 3. The storage box 1 communicates with the side wall of the compaction box 2 through the discharge pipe 11, and the compaction box 2 is connected to the dust collector. The collecting device 3 is connected; the top of the storage box 1 is provided with a material inlet 12, and the bottom is provided with a material outlet 13;

[0044] The compacting box 2 is a cube or a cuboid, and the first compacting device, the second compacting device and the third compacting device are arranged inside it, and the third compacting device is positioned at the top of the compacting case 2, and the first compacting device and The second compacting devices are respectively located on the side of the compacting box 2, and the first compacting device and the second compacting device are arranged symmetrically with respect to the third compacting device.

[00...

Embodiment 2

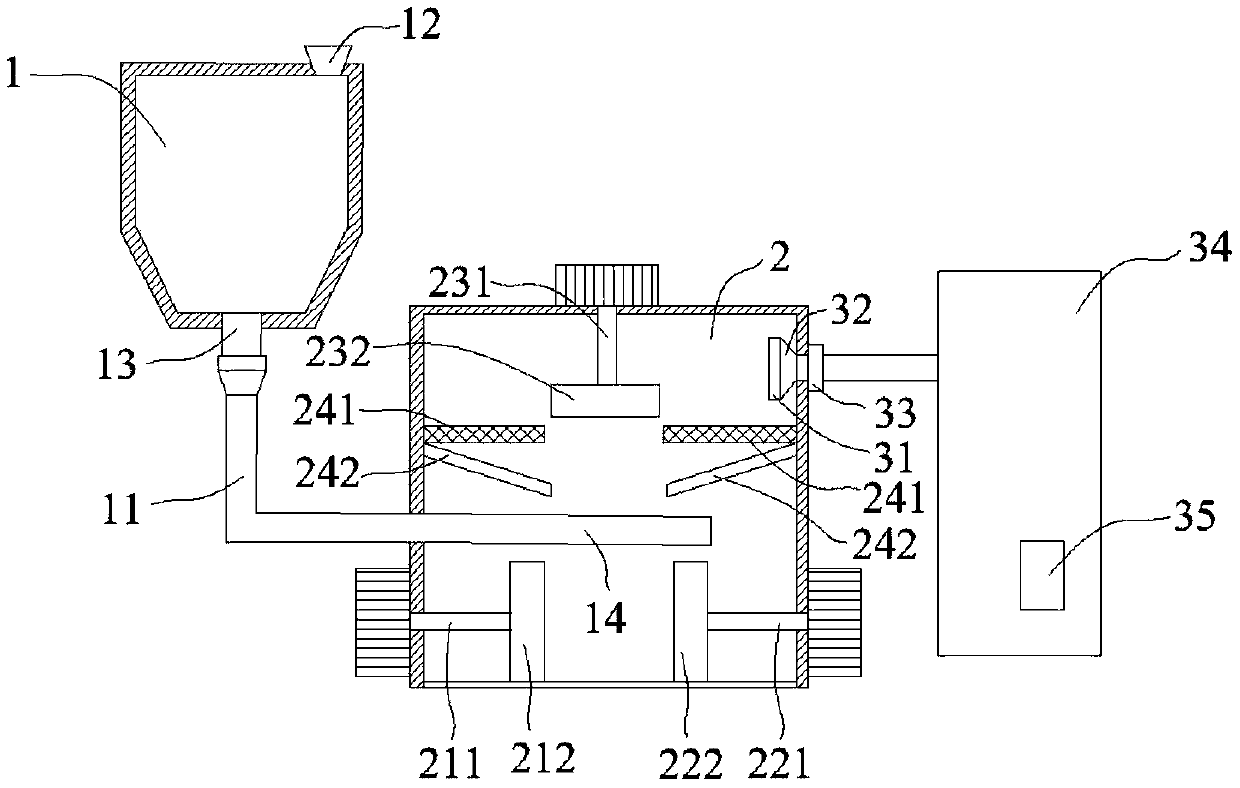

[0054] The difference between this embodiment and embodiment 1 is: as image 3 As shown, in the compaction box 2, a filter guide device is provided above the coil pipe 14, and the filter guide device includes a first filter screen 241 and a guide plate 242, the dust-proof screen 31 is located above the first filter screen 241, and the first filter screen 241 is arranged parallel to the bottom surface of the compaction box 2, the end of the first filter screen 241 is connected to the inner side wall of the compaction box 2, and the lower pressing plate 232 can pass through the first filter screen 241 to divide the first filter screen 241 into two, Make the first filter screen 241 symmetrically arranged with respect to the 3rd compacting device; The first filter screen 241 is connected, the guide plate 242 is arranged symmetrically with respect to the third compacting device, the lower pressing plate 232 can pass through the channel formed between the two guide plates 242, and t...

Embodiment 3

[0058] The difference between this embodiment and the above-mentioned embodiment is that: Figure 4 , Figure 5 and Figure 6 As shown, the side of the first side pressing plate 212 facing away from the first compression device is provided with a first baffle 213 perpendicular to the side, the first baffles 213 surround each other, and the side of the second side pressing plate 222 is away from the first compression device. A second baffle plate 223 perpendicular to the side is provided, and the second baffle plate 223 encloses each other. The first baffle plate 213 is provided with a plurality of first serrations 214, and the second baffle plate 223 is provided with a plurality of second serrations 224. The first sawtooth 214 on the first baffle 213 cooperates with the second serration 224 on the second baffle 223 ; the bottom of the lower pressing plate 232 is provided with a third baffle 233 perpendicular to the bottom.

[0059] The working principle of this embodiment: d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com