Forsterite-corundum sagger for sintering lithium battery powder and preparation method thereof

A forsterite and corundum sagger technology is applied in the field of forsterite-corundum saggar for sintering lithium battery powder and its preparation, which can solve the problems of peeling of the saggar, sagging and deformation of the bottom of the saggar, contamination of lithium battery powder, and the like. To achieve the effect of simple and feasible preparation method, increasing softening temperature under load, and increasing MgO content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

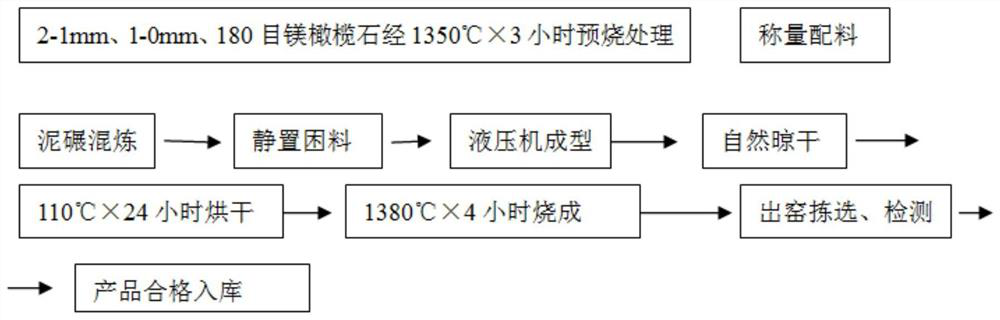

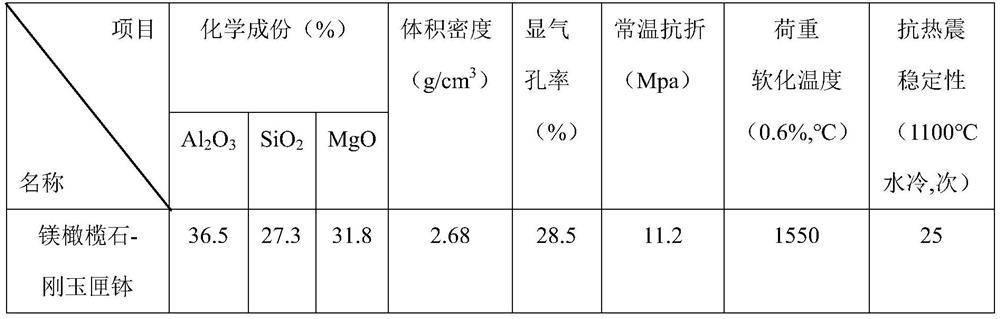

[0020] Weigh 35 parts of 2-1mm pre-burned forsterite, 10 parts of 1-0mm pre-burned forsterite, 15 parts of 180 mesh pre-burned forsterite, 6 parts of 325 mesh kaolin, 18 parts of 1-0mm sintered tabular alumina 16 parts of 1500-mesh activated alumina, plus 1 part of 100-mesh complexed magnesium-aluminum glue, plus 0.4 part of dextrin and 0.3 part of calcium lignosulfonate, put it into a mud mixer, and turn it at 15 rpm Speed, stirring for 25-30 minutes to fully mix the raw materials evenly, add 9 parts of water, stir and mix for 20 minutes to discharge the material, put it into the raw material barrel, and let it stand for 24 hours to trap the material. Use a hydraulic press to shape under a pressure of 350 tons; place the green body for 24 hours, and then enter the drying room for 110°C×24 hours to dry; then put the sagger into a high-temperature kiln and burn at 1380°C×4 hours. figure 1 , Among them, the pre-sintering method of forsterite is obtained by sintering it at a temp...

Embodiment 2

[0051] Weigh 30 parts of 2-1mm pre-burned forsterite, 8 parts of 1-0mm pre-burned forsterite, 12 parts of 160 mesh pre-burned forsterite, 8 parts of 300 mesh kaolin, 10 parts of 1-0mm sintered tabular alumina , 14 parts of 1600-mesh activated alumina, plus 2 parts of 80-mesh complexed magnesium-aluminum glue, plus 0.2 parts of dextrin and 0.1 part of calcium lignosulfonate, put it into the mud mixer, at a speed of 15 rpm , Stir for 25-30 minutes to fully disperse the raw materials, add 9 parts of water, stir and mix for 20 minutes to discharge the material, put it into the raw material barrel, and let it stand for 24 hours to trap the material. Use a hydraulic press to form under a pressure of 350 tons; place the green body for 24 hours, and then enter the drying room for drying at 100°C for 30 hours; then put the sagger into a high-temperature kiln and burn at 1200°C for 5 hours. The pre-sintering method is obtained by sintering it at 1300°C for 4 hours.

[0052] It can be s...

Embodiment 3

[0056] Weigh 33 parts of 2-1mm pre-burned forsterite, 9 parts of 1-0mm pre-burned forsterite, 13 parts of 160 mesh pre-burned forsterite, 4 parts of 350 mesh kaolin, 25 parts of 1-0mm sintered tabular alumina , 18 parts of 1500-mesh activated alumina, plus 2 parts of 120-mesh complexed magnesium-aluminum glue, plus 0.6 parts of dextrin and 0.5 parts of calcium lignosulfonate, put it into the mud mixer, at a speed of 15 rpm , Stir for 25-30 minutes to fully disperse the raw materials, add 9 parts of water, stir and mix for 20 minutes to discharge the material, put it into the raw material barrel, and let it stand for 24 hours to trap the material. Use a hydraulic press to form under a pressure of 350 tons; place the green body for 24 hours, and then enter the drying room for drying at 120°C for 20 hours; then put the sagger into a high-temperature kiln and burn at 1400°C for 3 hours. The pre-sintering method is obtained by sintering at 1400°C for 2 hours.

[0057] It can be se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com