High-wear-resistant and high-gloss coating for automobile interior trims and preparation method thereof

A high wear-resistant technology for automotive interiors, applied in the field of high wear-resistant high-gloss coatings for automotive interiors and its preparation, and single-layer high-gloss solvent-based coatings, which can solve the problems of environmental protection, energy saving, emission reduction, increased energy consumption and Discharge of harmful substances and other issues, to achieve the effect of high gloss, high wear resistance, high mirror gloss and blackness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In Example 1, the effect of the amount of acrylic resin A and acrylic resin B on the performance of the coating was investigated, wherein the items that are usually tested by those skilled in the art, namely appearance, adhesion and bending test, were selected for evaluation.

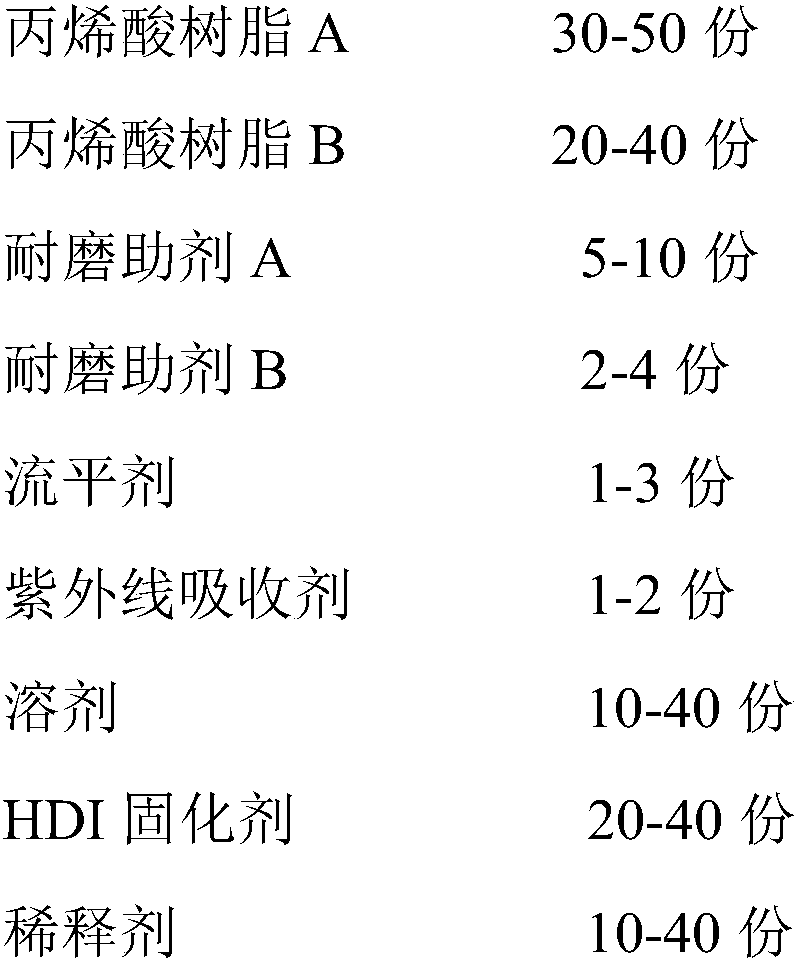

[0031] A kind of high wear-resistant high-gloss coating for automobile interior decoration of present embodiment 1 is made by the raw material that comprises following parts by weight: 5 parts of wear-resistant additive A (NANOBYK-3650 of BYK company), wear-resistant additive B (Japan Gifu company ZF-24F) 2 parts, leveling agent (BYK306) 2 parts, UV absorber (Tinuvin400) 1 part, solvent (butyl acetate: trimethylbenzene: ethyl lactate = 3:3:2) 30 parts, diluted Agent (butyl acetate: trimethylbenzene: ethyl lactate = 3:3:2) 40 parts, wherein, acrylic resin A (DUROFTAL VPI 2803 / 78BAC of Solutia), acrylic resin B (Uracron CY472 of DSM E-57) and the amount of HDI curing agent (Bayer N3390) are shown i...

Embodiment 2

[0040] This embodiment 2 investigated the impact of the amount of wear-resistant additive A and wear-resistant additive B on the performance of the coating. Among them, the popular PV3975-2010 commonly used by those skilled in the art was selected to detect the abrasion resistance of the coating, and the gloss retention The rate is the evaluation index.

[0041] A kind of high wear-resisting high-gloss paint for automotive interior of present embodiment 2 comprises the raw material of following weight portion, acrylic resin A (DUROFTAL VPI 2803 / 78BAC of Solutia Company) 40 parts, acrylic resin B (DSM Company's) ( Make up 100 parts of the mixed solution obtained in step (1), 30 parts of HDI (N3390) curing agent, 40 parts of diluent (butyl acetate: trimethylbenzene: ethyl lactate = 3:3:2), among which, wear-resistant The amount of additive A (NANOBYK-3650 from BYK Company) and wear-resistant additive B (ZF-24F from Gifu, Japan) is shown in Table 2. The first group only added we...

Embodiment 3

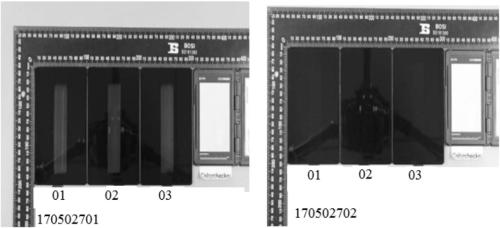

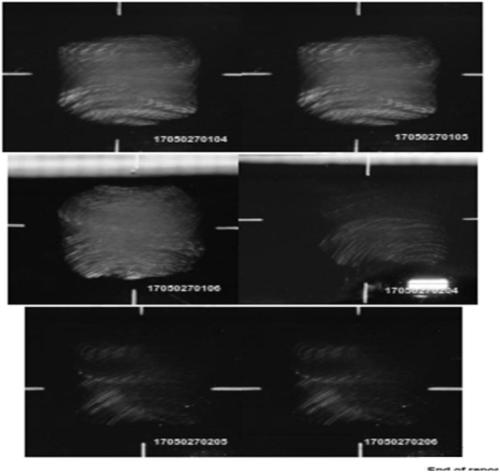

[0047] Example 3 is divided into two groups, and this is used as an experimental group, and three parallel experiments are set for each group; in addition, a control group is also set, and three parallel experiments are also set for the control group. The experimental group is 17050270201-17050270206, and the control group is 17050270101-17050270106. Among them, 17050270101-03 and 17050270201-03 have been tested by Volkswagen PV3987-2016, and 17050270104-06 and 17050907-207-0204 have been tested by Volkswagen 0PV3.

[0048] The automotive interior paint of the control group is the product of Pater Chemical Industry (Shanghai) Co., Ltd. trade mark: P68934, and each raw material component and content, preparation method in the control group, the substrate sprayed and the spraying method are all the same.

[0049] Each raw material component and content, preparation method in the experimental group, the base material that is sprayed and spraying method are also all the same, see b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com