Novel coal roadway rapid excavator

A roadheader and coal roadway technology, which is applied in the field of new coal roadway fast roadheaders, can solve the problems of low safety factor and low work efficiency, and achieve the effects of strong geological adaptability, high excavation efficiency, and improved working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

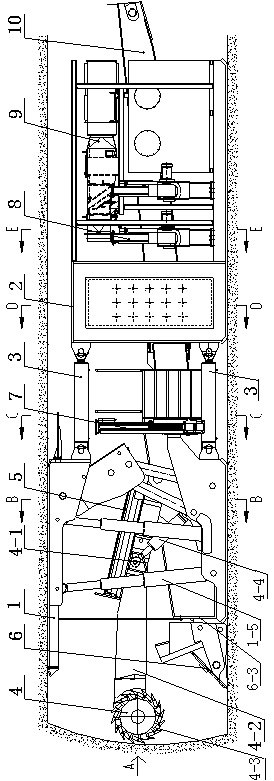

[0022] Example 1, such as figure 1 As shown in the figure, a new type of rapid tunneling machine for coal roadway includes an adjustable shield body 1 and a rear support shield 2. The adjustable shield body 1 is connected with the rear support shield 2 through four propulsion cylinders 3, and the four propulsion cylinders stretch to realize the whole Step change and direction adjustment of machine equipment. The adjustable shield body 1 is provided with a cutting device 4 and an advanced drilling machine 5. The cutting device 4 swings up and down through the power provided by the hydraulic system to realize excavation of a rectangular section. The advanced drilling rig 5 performs advanced geological exploration operations through hydraulic control. The lower part of the adjustable shield body 1 is provided with a shoveling device 6, which collects the coal or rock excavated by the cutting device. A top bolter system 7 is arranged between the adjustable shield body 1 and the ...

Embodiment 2

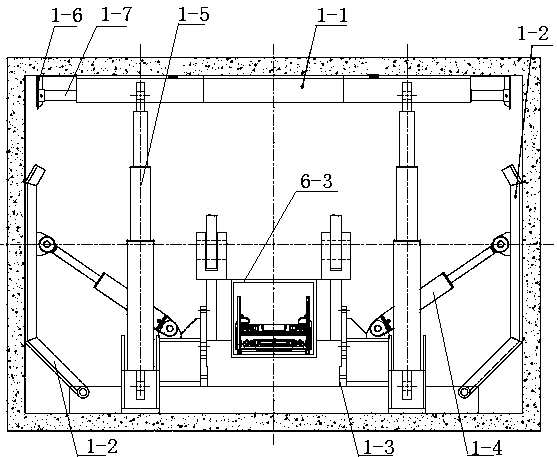

[0023] Example 2, such as Figure 2-6 As shown, a new coal roadway rapid tunneling machine, the adjustable shield body 1 includes a top shield 1-1, a side shield 1-2 and a bottom shield 1-3, and the side shield 1-2 is symmetrically arranged on On both sides of the bottom shield 1-3, the lower part of the side shield 1-2 is hinged to the bottom shield 1-3, and the inner wall of the side shield 1-2 is provided with a lateral oil cylinder 1-4, and the lateral oil cylinder 1- One end of 4 is connected to the side shield 1-2, and the other end is connected to the bottom shield 1-3. Through the expansion and contraction of the lateral oil cylinder, the side shield rotates around the hinge point to realize the tight support of the side shield to the roadway. protect. The inner wall of the top shield 1-1 is provided with a top-facing oil cylinder 1-5, one end of the top-facing oil cylinder 1-5 is connected with the top shield 1-1, and the other end of the top-facing oil cylinder 1-5 ...

Embodiment 3

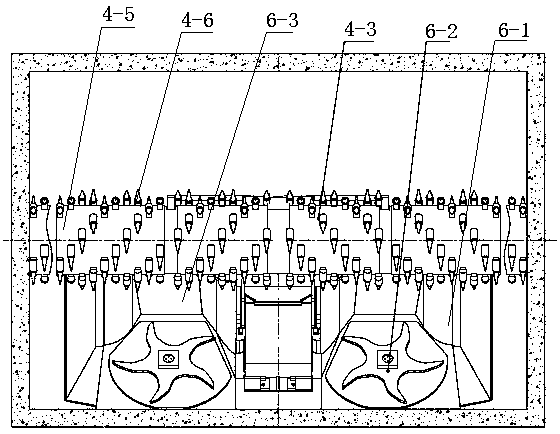

[0027] Embodiment 3, a new type of rapid roadheader for coal roadway, the scraper device 6 includes a bucket 6-1, and the lower surface of the bucket 6-1 is provided with a slag removing tooth plate 6-2, which is used to remove coal and soil sent to the bucket, the rear of the bucket 6-1 is provided with a slag delivery channel 6-3, the slag delivery channel 6-3 is connected with the slag conveying system 10, and the slag conveying system 10 adopts a scraper conveyor. For the transportation of coal soil or rock soil. Two groups of brace shoes 2-1 are arranged symmetrically inside the rear support shield 2, and the two groups of brace shoes 2-1 are connected through the brace cylinder 2-2, and the brace cylinder is set horizontally, and the brace shoes can realize left and right expansion and contraction through the control of the cylinder . The stretching out of the tensioning cylinder realizes that the strut shoe is tightened on the wall of the cave, which can provide the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com