Method and system for coolant temperature control in vehicle propulsion system

A propulsion system and coolant technology, applied in coolant flow control, liquid cooling, engine cooling, etc., can solve problems such as slow response to temperature changes, achieve accurate temperature control, reduce the risk of deviation from the target temperature, reduce Effect of Small Calibration Effort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

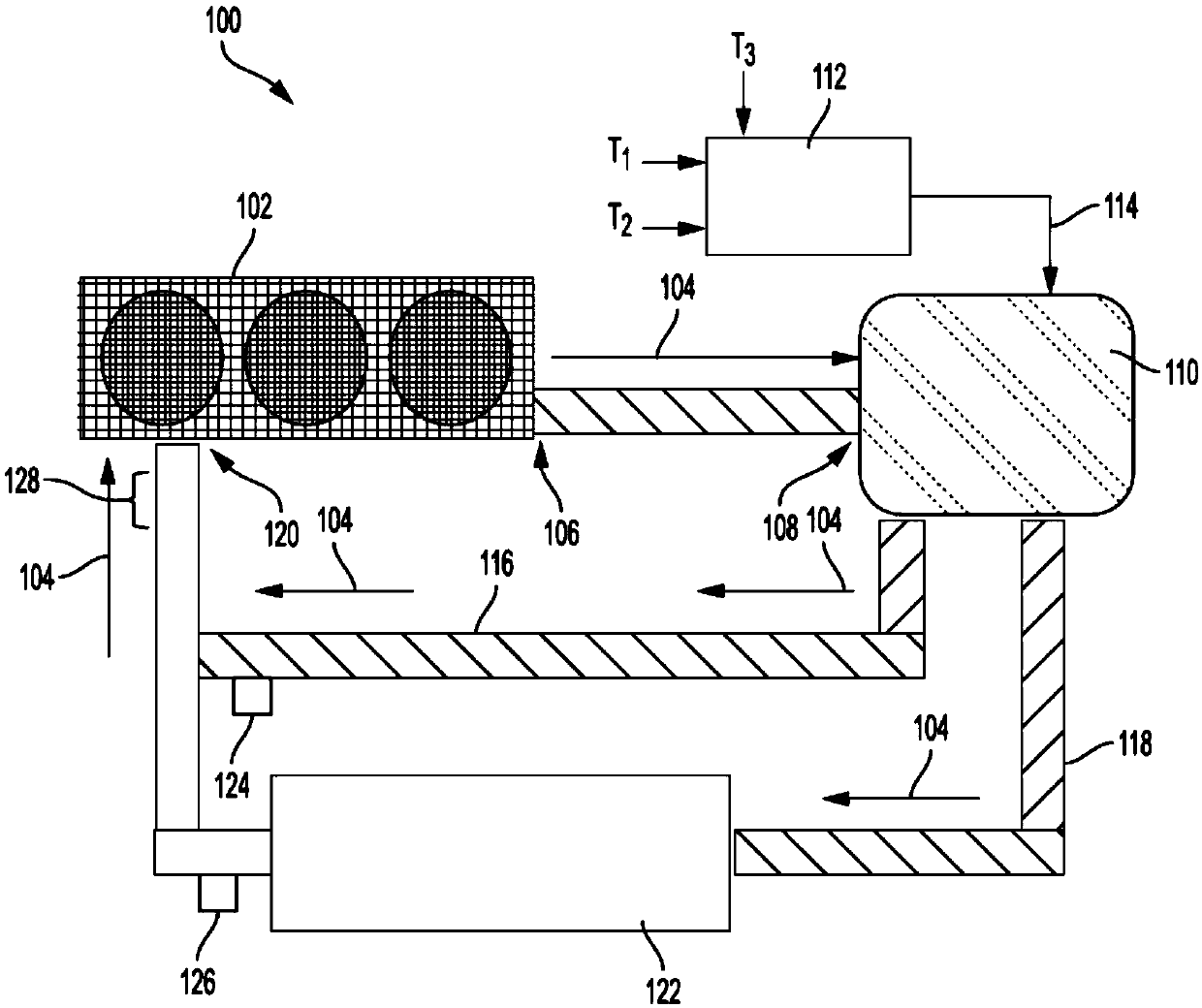

[0021] Thermal management of prime movers (such as, for example, engines, motors, battery packs, etc.) in vehicle propulsion systems can be critical for optimal performance, reliability, and durability. figure 1 A thermal management system 100 in a vehicle propulsion system is illustrated. The thermal management system includes a prime mover 102 that provides power to the vehicle propulsion system. For example, prime mover 102 may be an internal combustion engine, an electric motor, etc. (without limitation). Operation of prime mover 102 may require temperature management to optimize efficiency, economy, performance, and the like. The thermal management system 100 circulates coolant throughout the system 100 in a manner that enables the temperature of the engine to be managed, as generally indicated by arrows 104 . Coolant exits the engine 102 at a coolant outlet 106 and flows to an inlet 108 of a coolant control valve 110 . The coolant control valve 110 communicates with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com