Train end blocking device for air tightness test

A plugging device and air-tightness technology, which is applied in the direction of fluid tightness testing, measuring devices, liquid-tightness measurement using liquid/vacuum degree, etc., can solve the problem of fragile structure of plastic plates, low efficiency, loose filling and leakage Gas and other problems, to achieve universal and good airtight performance, improve operating efficiency, good universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

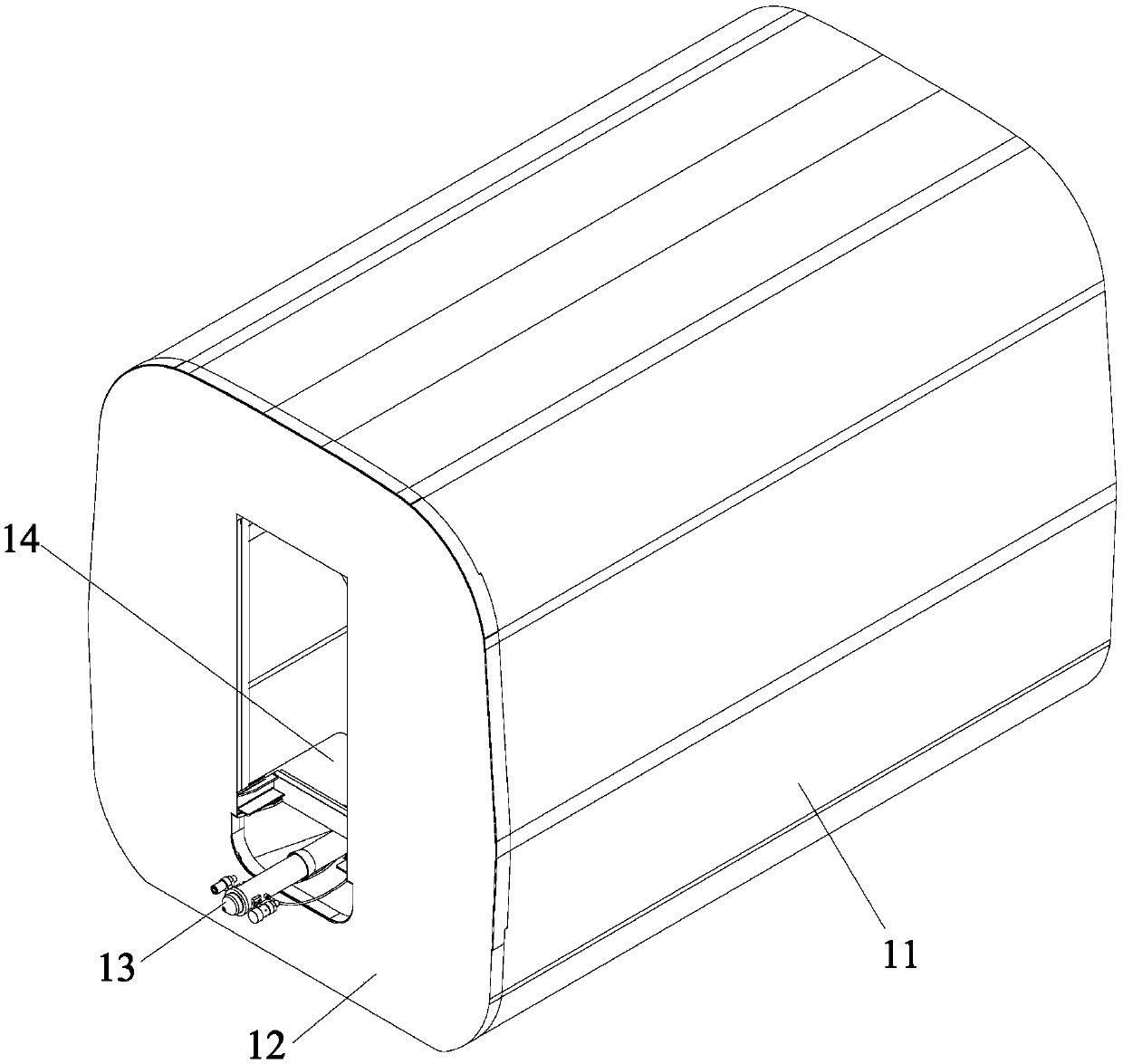

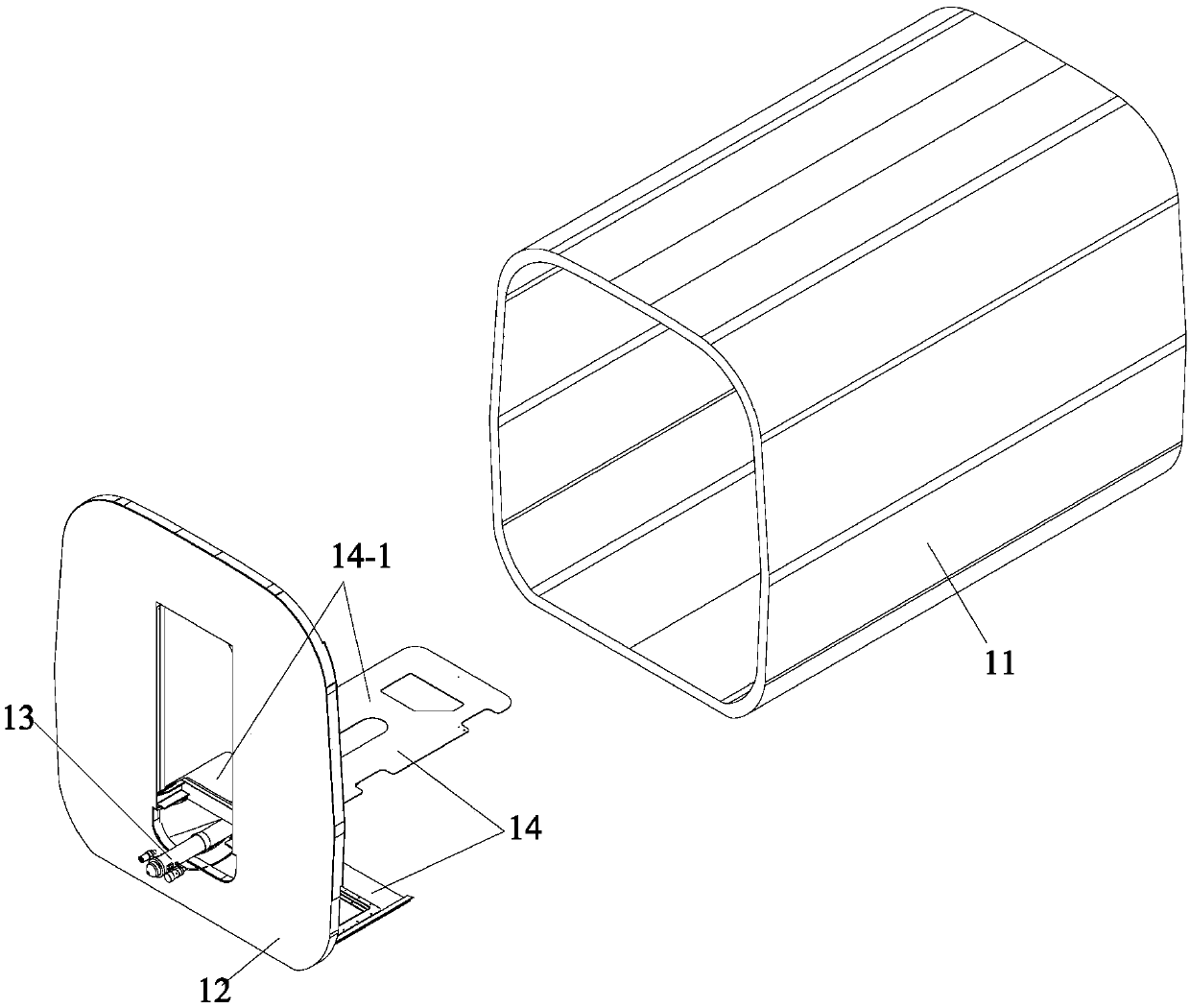

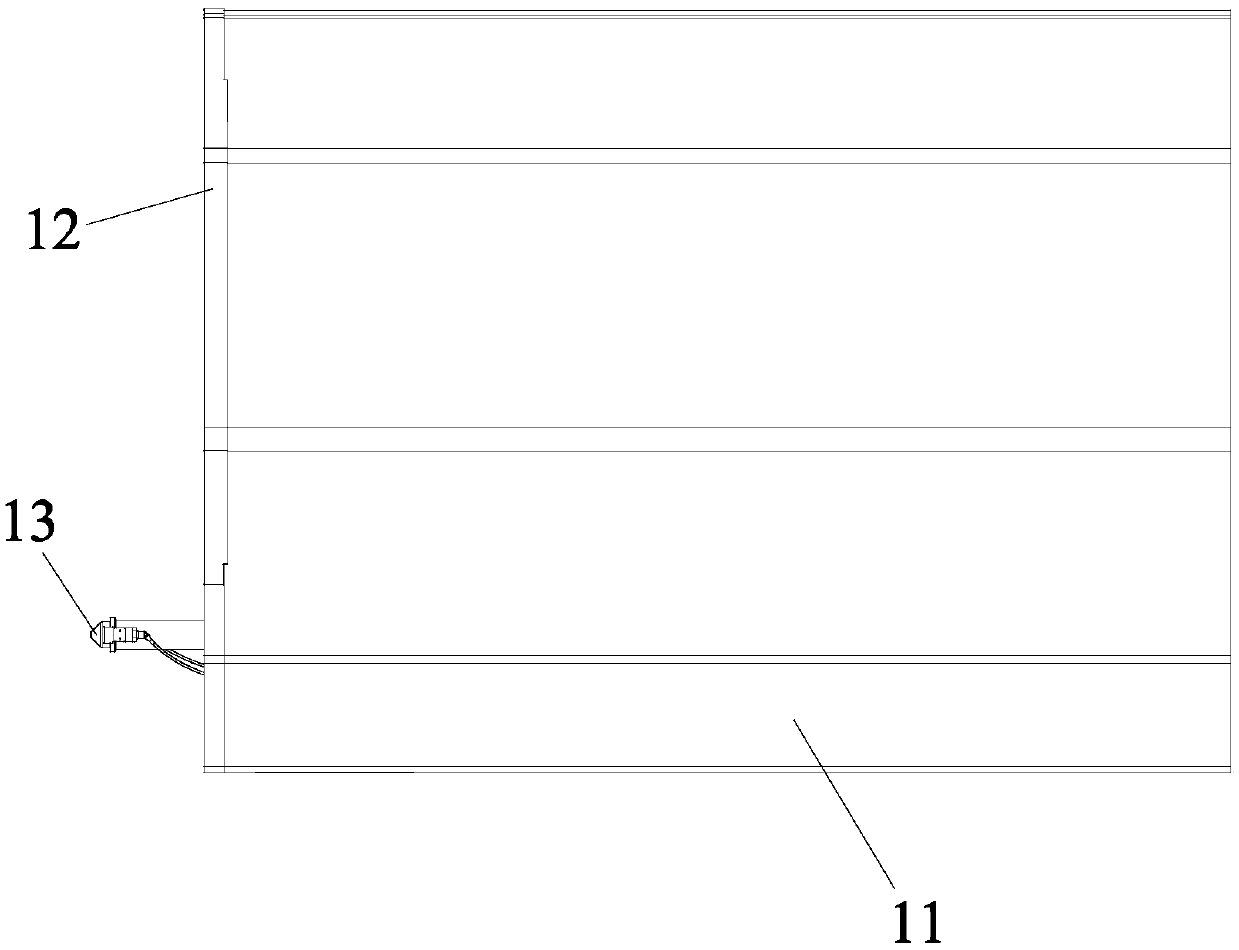

[0043] Such as Figure 7 to Figure 17 As shown, the train end sealing device for air tightness test of the present invention includes a mobile trolley 1, a support frame 2, a vertical adjustment frame 3, a cylinder 4, two limit bolts 5, and a horizontal and pitch adjustment mechanism 6 , Metal blocking plate 7, coupler blocking box 8, two positive and negative pressure cut-off valves 9 and electric control safety valve 10.

[0044] The bottom of the four corners of the mobile trolley 1 is fixedly connected with a track wheel 1-1 for traveling on the track, the bottom of the support frame 2 is fixed on the mobile trolley 1, and the inner sides of the upper two ends of the support frame 2 are respectively provided with a frame The guide rail 2-1 and the two limit bolts 5 are respectively fixedly connected to both sides of the upper part of the support frame 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com