Test device for simulating horizontal earthquake action of node in framework beam column

A technology for simulating a frame and a test device, applied in the field of civil engineering, to achieve the effect of enhancing the ability to bear force and resisting deformation, increasing the overall stiffness, and having a large coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

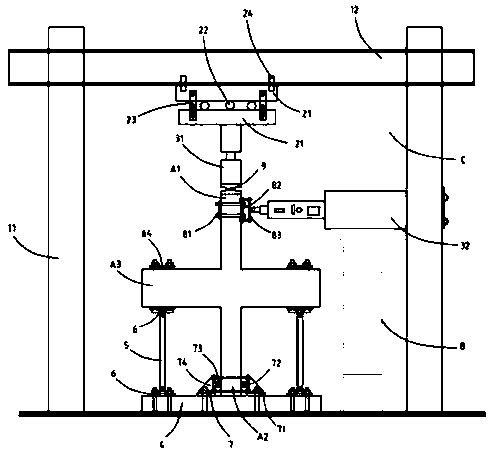

[0035] Such as figure 1 As shown, there is provided a test device for simulating the horizontal seismic action of the nodes in the frame beam and column, including a reaction rigid frame fixed to the ground. The reaction rigid frame is formed by two vertical support frames 11 and a horizontal support frame 12 The frame structure is stabilized, the beam-column node test piece is located in the reaction frame, and a jack 31 is connected to the horizontal support frame 12 through a connecting structure. The axial compression loading device in this embodiment is the jack 31, and the jack 31 and the beam-column node test piece The top of the column is hinged by the hinged support 9 and pressure can be applied to the top A1 of the beam-column node specimen (when the beam-column node specimen is initially pressed, the pressure is applied in the direction of the column axis); It includes an electro-hydraulic servo actuator 32 that can apply horizontal force to the side of the column end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com