Remote operation model based on virtual machine structure and construction method thereof

A virtual machine and remote technology, which is applied to the remote operation and maintenance model based on virtual machine structure and its construction field, can solve the problems of wasting manpower and material resources, and unable to comprehensively analyze monitoring indicators at any time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 A remote operation and maintenance model based on virtual machine structure

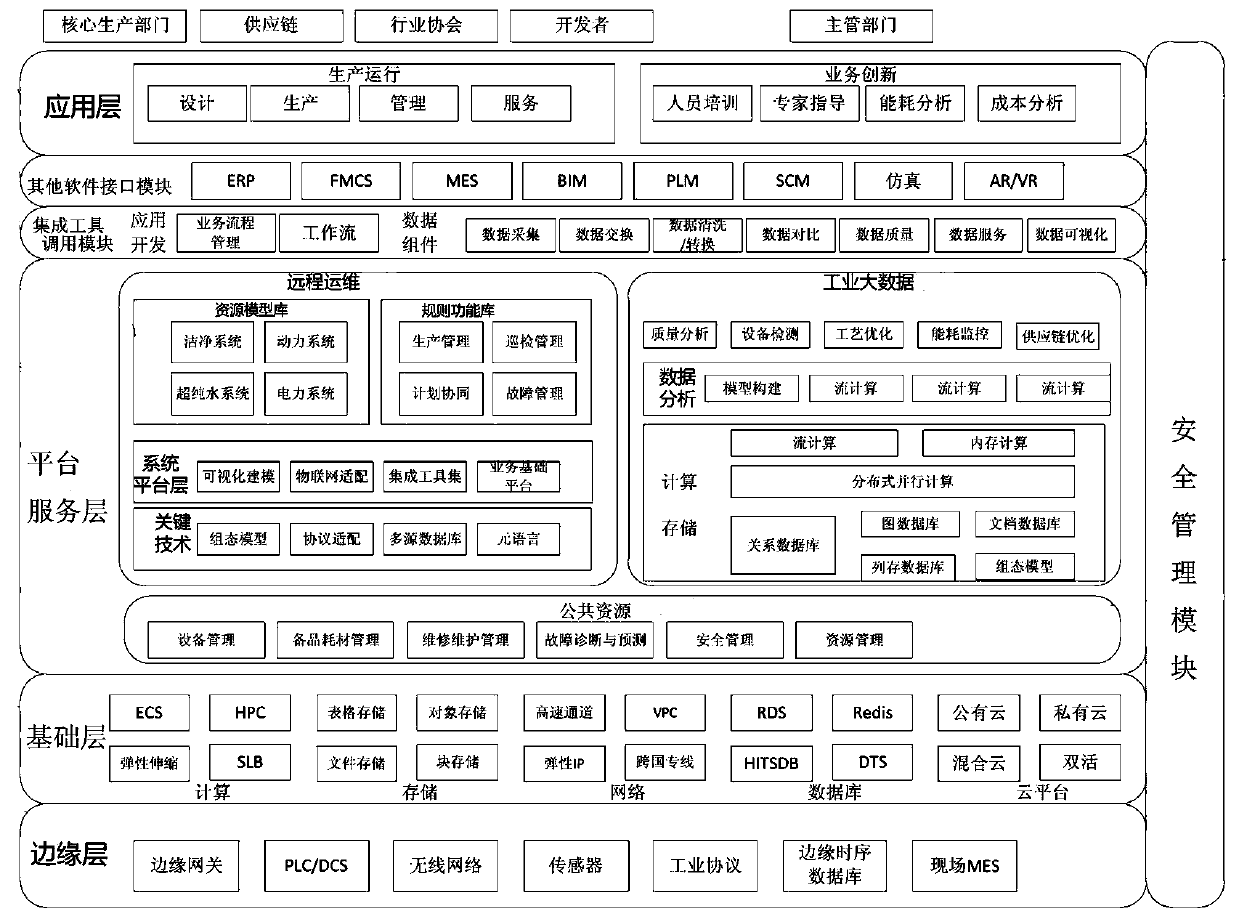

[0034] Such as figure 1 The illustrated embodiment includes an edge layer, a base layer, a platform service layer, an integration tool module, other software interface modules, and an application layer arranged sequentially from bottom to top. This embodiment also includes a security management module. in,

[0035] ① Edge layer

[0036] The edge layer includes edge gateway, programmable logic controller PLC / distributed control system DCS, wireless network, sensor, industrial protocol, edge timing database and on-site manufacturing enterprise production process execution system MES;

[0037] The edge layer is also the communication and perception layer. It is located at the bottom of the entire remote operation and maintenance model. It has functions such as data collection, communication, and remote control. It uses the industrial Internet that supports IPv4, IPv6 and other tec...

Embodiment 2

[0050] Embodiment 2 A construction method of a remote operation and maintenance model based on a virtual machine structure

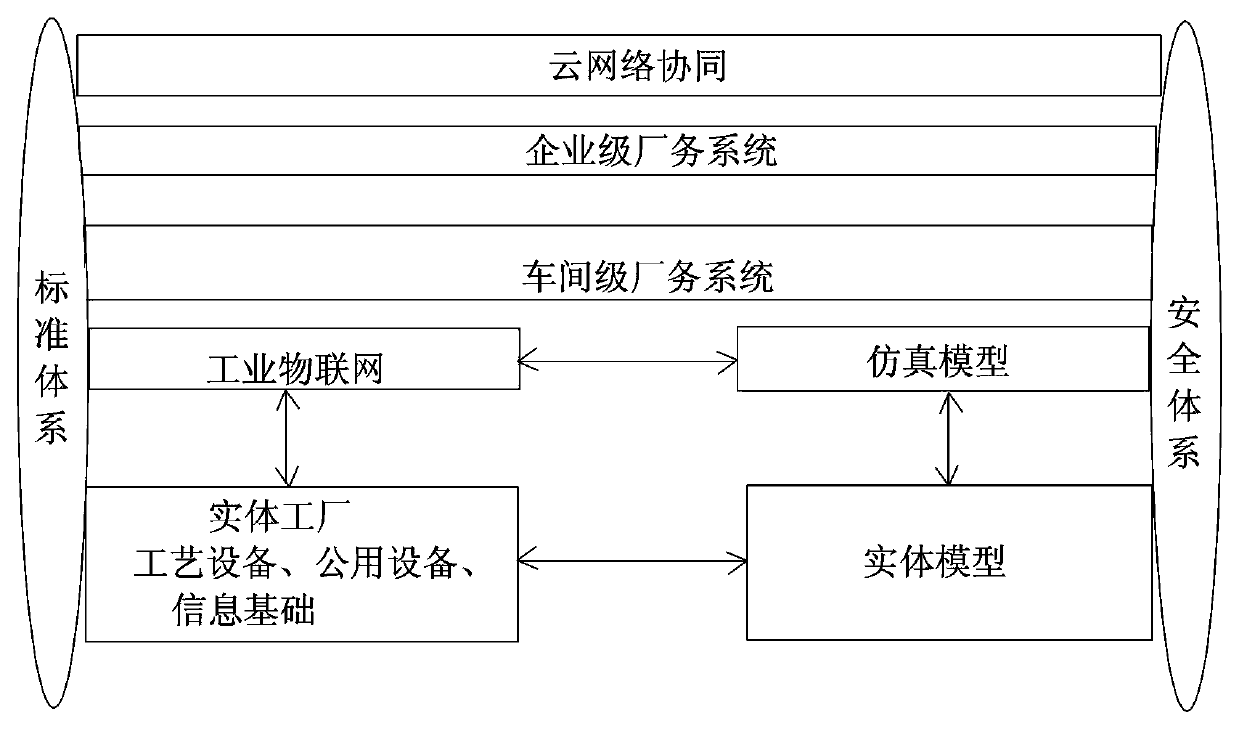

[0051] Such as figure 2 As shown, this embodiment includes the following processes:

[0052] 1. Establish physical model and simulation model

[0053] Virtualize the physical equipment and automation process of the factory, and map the process equipment, public equipment, information infrastructure, and the process control of the three into the physical model through the mapping relationship;

[0054] Make the equipment of the physical factory into the industrial Internet of Things, and map it to the simulation model in the form of digital twins;

[0055] The above two processes adopt a synchronization mechanism;

[0056] In the process of establishing the physical model, set up the sensor IoT of the physical factory to form the basis of the edge layer;

[0057] 2. Establish a production execution system at the workshop level and factory level, establ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com