Oil-reduced extruded pastry

A technology of cakes and extrudates, which is applied in food science, food preservation, food ingredients as taste improvers, etc. It can solve the problems of product quality deterioration and achieve the effects of easy hardening, oil absorption capacity, and flavor enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

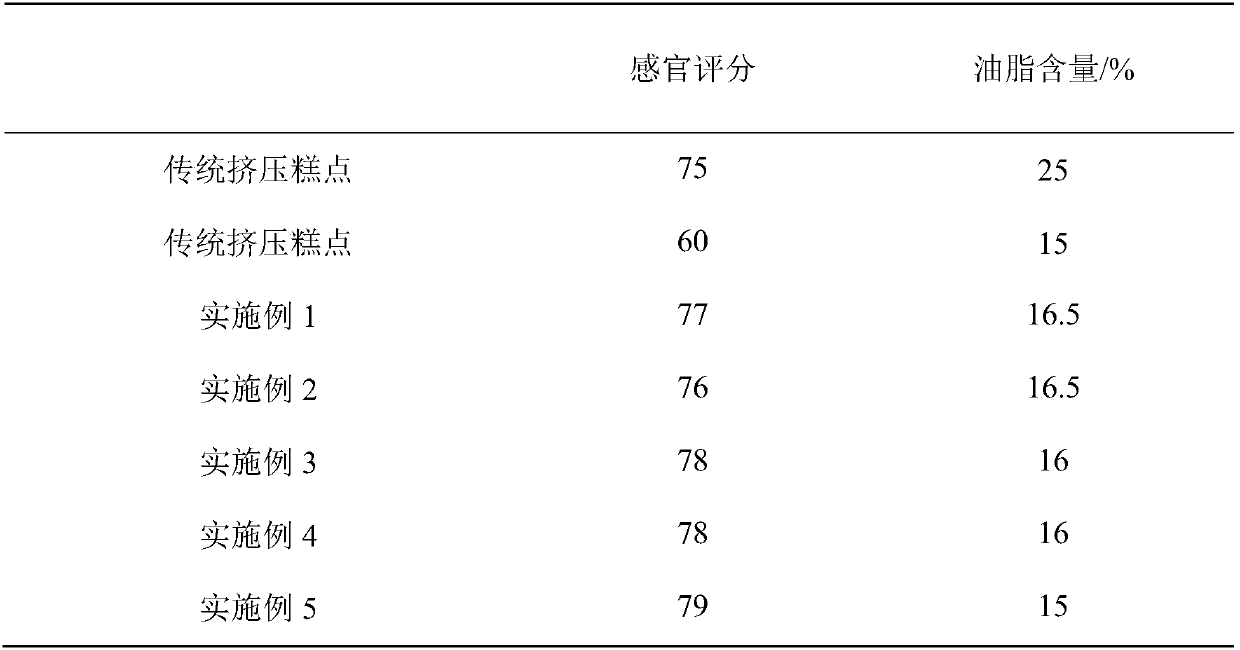

Examples

Embodiment 1

[0027] The present embodiment provides a reduced-oil extruded pastry and a preparation method thereof. In parts by weight, the dosage of the chromium component is: 400 parts of wheat flour, 100 parts of Moringa leaf powder, 30 parts of table salt, 20 parts of fructose syrup, 0.5 parts of glycerin, 30 parts of water.

[0028] The preparation method is:

[0029] S1: Take fresh leaves of Moringa oleifera, wash them, and dry them with hot air at 50°C until the surface is dry and brittle;

[0030] S2: Put the dried leaves in S1 into a twin-screw extruder for crushing. Pass through a 80-mesh sieve and retain the undersize;

[0031] S3: Add the sieved material in S2 to wheat flour with similar quality, mix thoroughly and then add to the remaining wheat flour;

[0032] S4: Add brine to the mixed powder in S3, knead into flour flocculation, extrude and mature through a single-screw extrusion extruder to obtain a semi-finished product.

[0033] S5: mixing the semi-finished extruded ...

Embodiment 2

[0036] The difference from Example 1 is that the dosage of each component is: 600 parts of wheat flour, 60 parts of Moringa leaf powder, 50 parts of table salt, 40 parts of fructose syrup, and 2.5 parts of monoglyceride.

[0037] The ingredients used include 51 parts by weight of rapeseed oil and 51 parts by weight of Moringa seed oil.

Embodiment 3

[0039] The difference from Example 1 is that the dosage of each component is: 450 parts of wheat flour, 90 parts of Moringa leaf powder, 35 parts of table salt, 25 parts of fructose syrup, and 1.0 part of monoglyceride.

[0040] The ingredients used include 38 parts by weight of rapeseed oil and 38 parts by weight of moringa seed oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com