Filtration sterilization device and process for sterile medicines

A technology for filtration, sterilization, and medicine, applied in filtration, filtration separation, water supply devices, etc., can solve the problems of loss, increased production cost, easy to block filter elements, etc., to improve the level of sterility assurance, reduce losses, and reduce risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

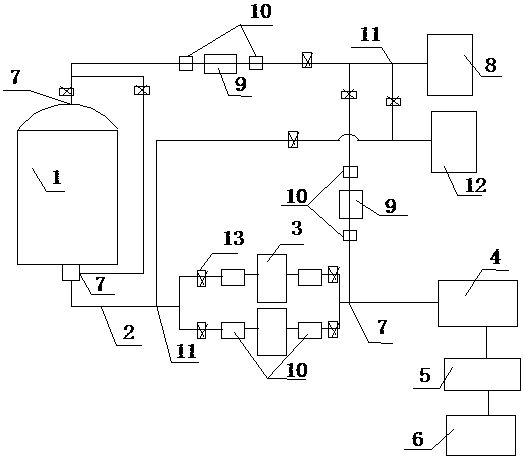

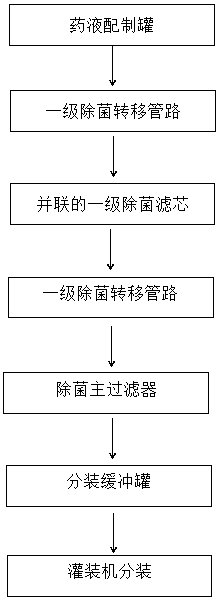

[0035] Such as figure 1 As shown, a sterile drug filtration and sterilization device includes a drug solution preparation tank 1. The discharge port of the drug solution preparation tank 1 is connected to a first-level sterilization filter 3 and a main filter through a sterilization transfer pipe 2 in turn 4 is connected, the discharge port of the main filter 4 is connected to the sub-packing buffer tank 5 and the filling machine 6 in turn through a pipeline, the first-stage sterilization filter is arranged in parallel, and the first-stage sterilization filter A compressed air inlet 7 is provided on the sterilization transfer pipeline behind the device, and the compressed air inlet is connected to a compressed air source 8 through the pipeline.

[0036] The upper end of the medicinal solution preparation tank 1 is provided with a compressed air inlet 7, which is connected to a compressed air source 8 through a pipe.

[0037] An air filter 9 is arranged on the pipeline between the c...

Embodiment 2

[0044] A sterile drug filtration and sterilization process is performed by using the device described in Example 1, and specifically includes the following steps:

[0045] (1) Preparation process for sterilization

[0046] 1) First, clean the device with water for injection;

[0047] 2) Check the membrane integrity of the primary filter, main filter and air filter before use;

[0048] 3) Carry out pure steam online sterilization on the air filter and the sterilization transfer pipeline after the primary sterilization filter. At this time, the sterilization transfer pipeline is connected to the main filter for the tooling generation connection;

[0049] 4) Clean the main filter, the sub-packing buffer tank, the filling machine and the connecting pipeline between the three. After cleaning, wrap the opening with a breathing bag and place it in a pulsating vacuum sterilization cabinet for humid and hot steam sterilization ;

[0050] 5) Disassemble the tooling where the sterilization transfe...

Embodiment 3

[0059] A sterile drug filtration and sterilization process is performed by using the device described in Example 1, and specifically includes the following steps:

[0060] 1. Prepare the two-stage sterilization filter, liquid medicine transfer pipeline, buffer tank and filling equipment before use.

[0061] 1.1 First, clean the filter housing, pipes and other appliances of the sterilization filter with water for injection, which should meet the cleaning requirements before use.

[0062] 1.2 Check the membrane integrity of the sterile filter element before use.

[0063] 1.3 Perform pure steam online sterilization on the compressed air sterilization filter and the pipeline after the primary sterilization filter. At this time, the end of the liquid medicine transfer pipeline is connected to the main filter for tooling connection.

[0064] 1.4 Clean the main filter, buffer tank, filling needle, and pipeline before use. After they are connected, wrap the opening with a breathing bag and pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com