Processing method for cadmium adsorbent with use stability

A processing method and adsorbent technology, which are applied in the processing field of cadmium adsorbents, can solve problems such as limiting the use range of products and discounting adsorption capacity, and achieve the effects of broadening applicability, enhancing use capacity, and improving adsorption efficiency and effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A processing method using a stable cadmium adsorbent, comprising the steps of:

[0032] (1) Raw materials are weighed for backup:

[0033] First take the following raw materials according to the corresponding parts by weight for later use: 5 parts of chitosan, 30 parts of silica gel, 0.3 part of magnetic rare earth material, 5 parts of binder;

[0034] (2) Raw material processing:

[0035] a. Put the chitosan weighed in step (1) into dilute hydrochloric acid with a total mass of 75 times, and keep stirring to obtain a chitosan solution for subsequent use after 25 minutes;

[0036] b. Put the silica gel weighed in step (1) into an incubator for heat preservation and activation treatment, and take out the activated silica gel after 1 hour for use;

[0037] c. Put the magnetic rare earth material weighed in step (1) into a ball mill for ball milling, and ball mill it until the particle size is 10-30 μm, then take it out for later use;

[0038] (3) Blending processing: ...

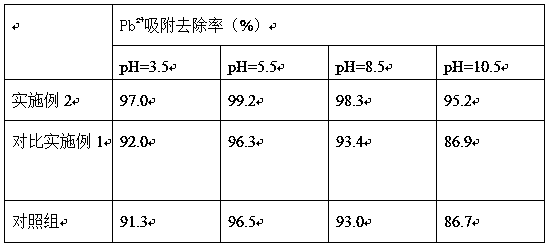

Embodiment 2

[0052] A processing method using a stable cadmium adsorbent, comprising the steps of:

[0053] (1) Raw materials are weighed for backup:

[0054] First take the following raw materials according to the corresponding parts by weight for later use: 6 parts of chitosan, 40 parts of silica gel, 0.5 part of magnetic rare earth material, 8 parts of binder;

[0055] (2) Raw material processing:

[0056] a. Put the chitosan weighed in step (1) into dilute hydrochloric acid whose total mass is 80 times, and keep stirring to obtain the chitosan solution for subsequent use after 27min;

[0057] b. Put the silica gel weighed in step (1) into an incubator for heat preservation and activation treatment, and take out the activated silica gel after 1.5 hours for use;

[0058] c. Put the magnetic rare earth material weighed in step (1) into a ball mill for ball milling, and ball mill it until the particle size is 10-30 μm, then take it out for later use;

[0059] (3) Blending processing:

[...

Embodiment 3

[0073] A processing method using a stable cadmium adsorbent, comprising the steps of:

[0074] (1) Raw materials are weighed for backup:

[0075] First take the following raw materials according to the corresponding parts by weight for later use: 7 parts of chitosan, 45 parts of silica gel, 0.8 part of magnetic rare earth material, 9 parts of binder;

[0076] (2) Raw material processing:

[0077] a. put the chitosan weighed in step (1) into dilute hydrochloric acid with a total mass of 85 times, and keep stirring to obtain a chitosan solution for subsequent use after 30 min;

[0078] b. Put the silica gel weighed in step (1) into an incubator for heat preservation and activation treatment, and take out the activated silica gel after 2 hours for use;

[0079] c. Put the magnetic rare earth material weighed in step (1) into a ball mill for ball milling, and ball mill it until the particle size is 10-30 μm, then take it out for later use;

[0080] (3) Blending processing:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com