Five-axis hybrid machine tool for machining aviation structural parts

A technology for aerospace structural parts and machine tools, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc. It can solve the problems of few and insufficient configurations, and the advantages of aerospace structural parts have not been fully utilized, etc., to achieve good processing accuracy , high processing efficiency, and the effect of avoiding milling damage to the surface of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific structure and working process of the present invention will be further described below in conjunction with the accompanying drawings.

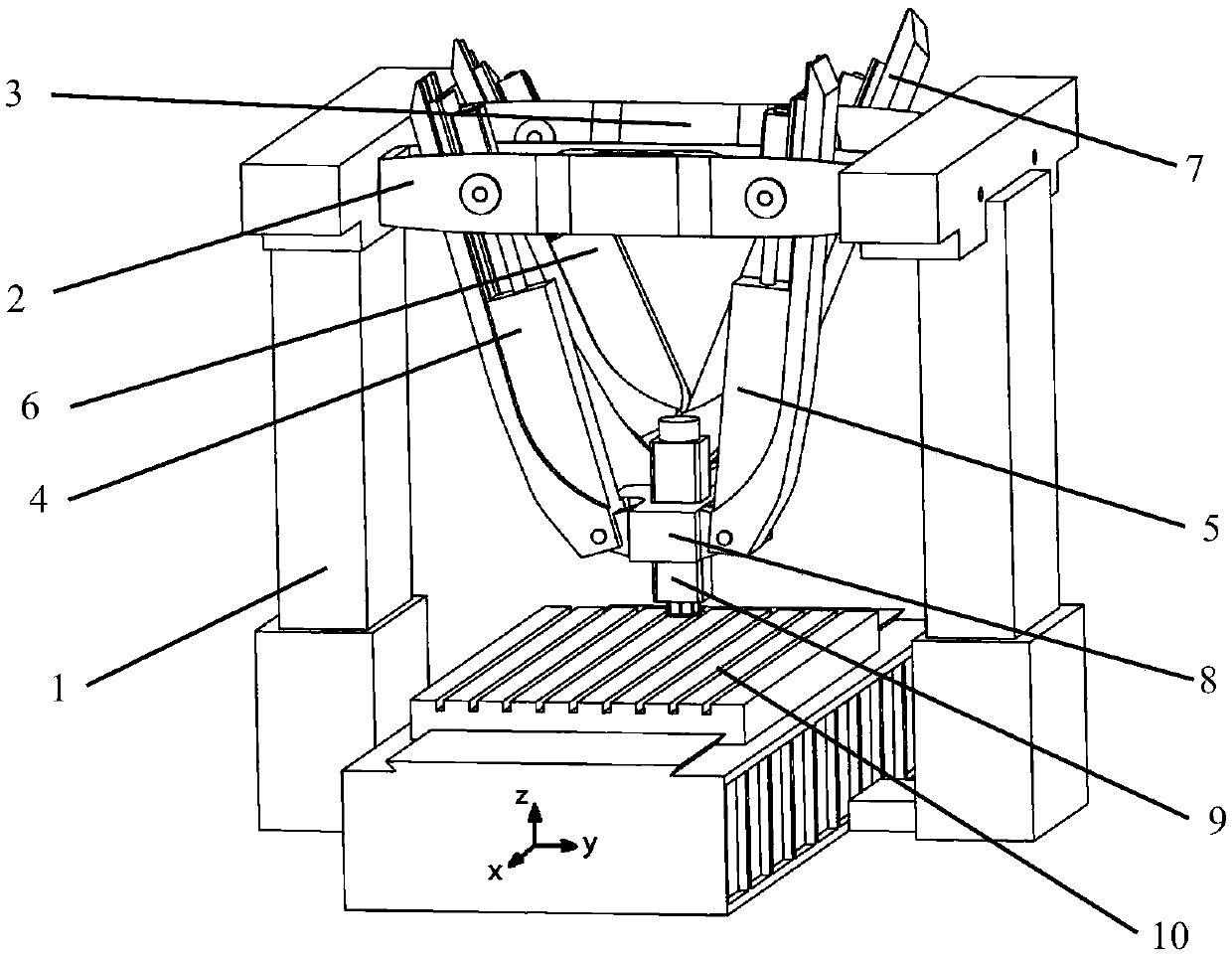

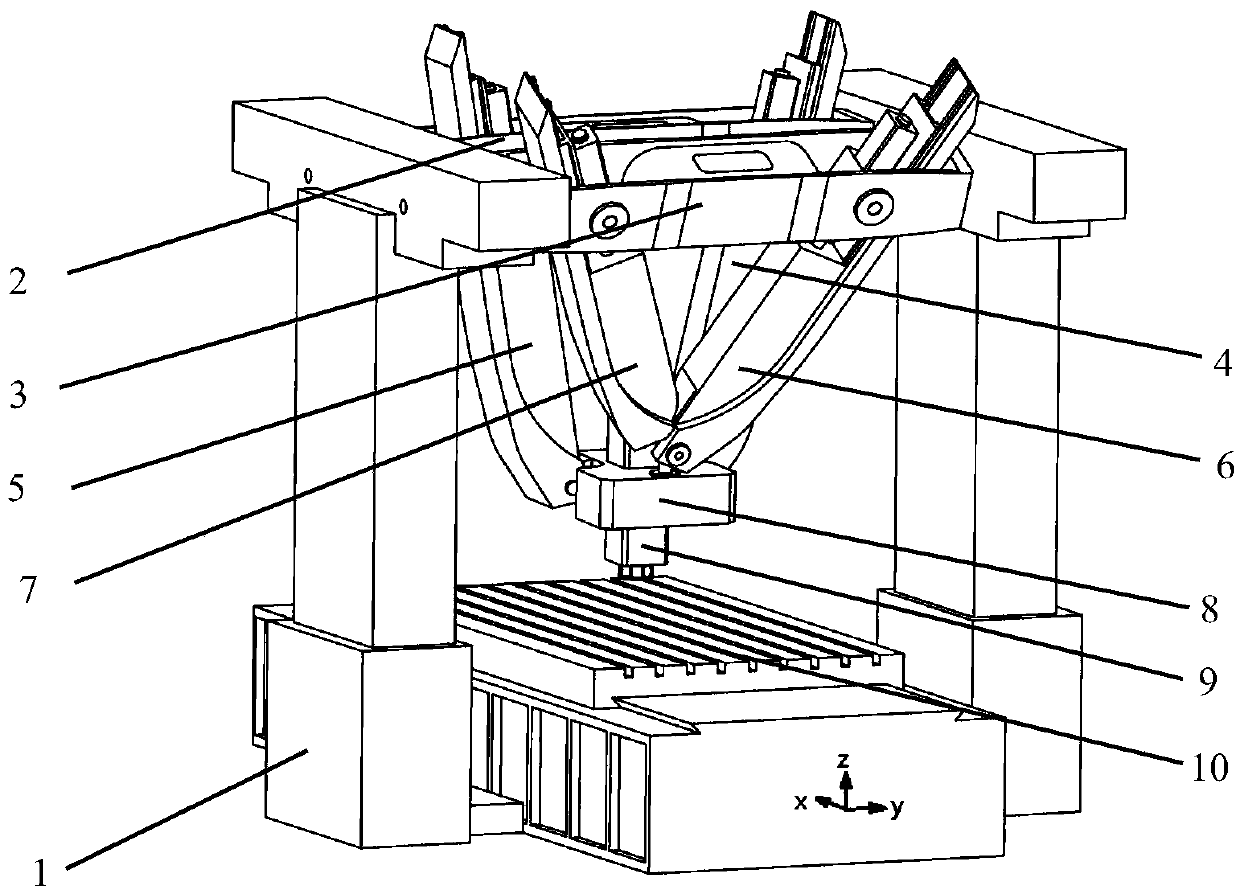

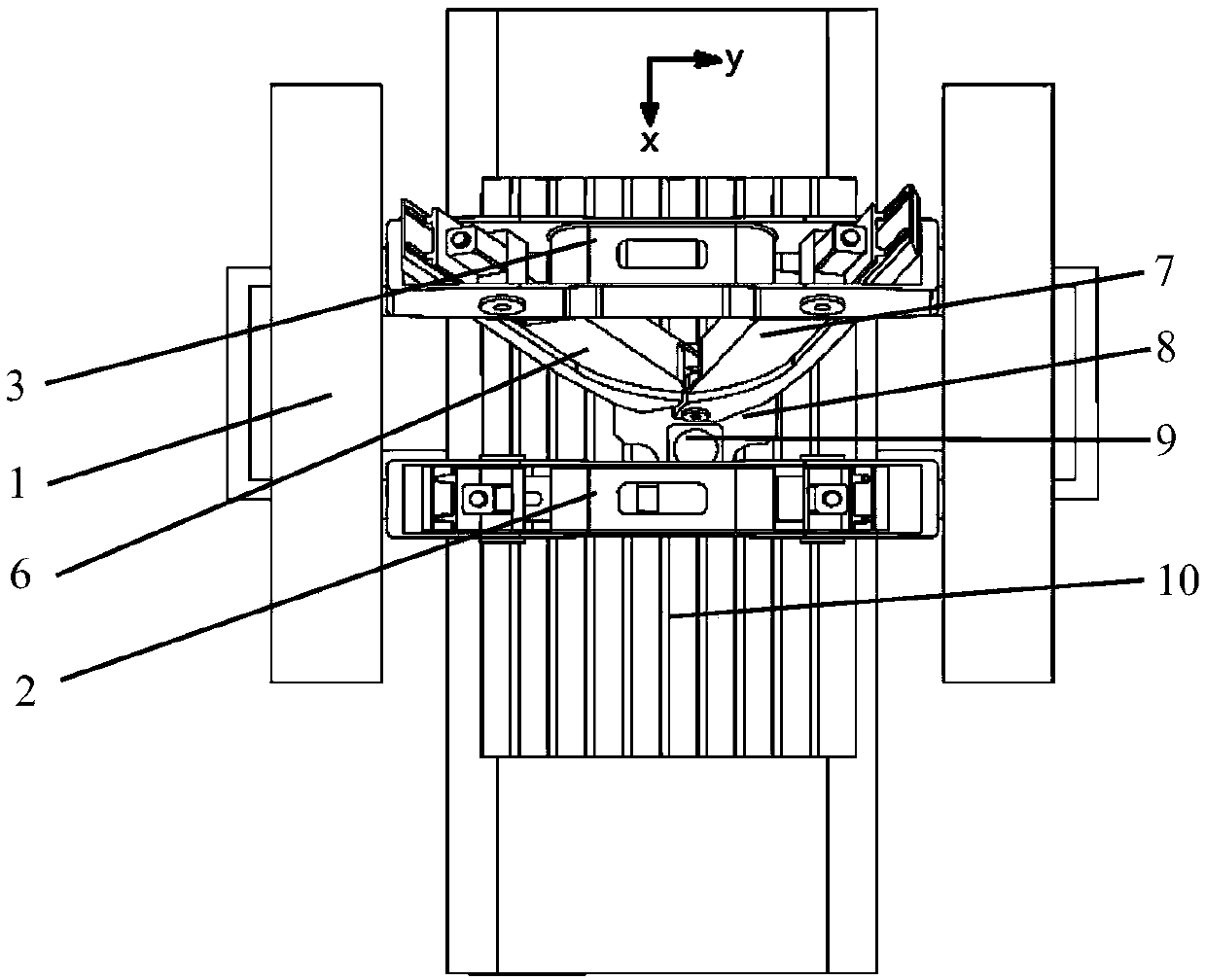

[0018] see figure 1 , figure 2 with image 3 , a five-axis hybrid machine tool proposed by the present invention for machining aeronautical structural parts mainly includes a bracket 1, a front beam 2, a rear beam 3, a first branch chain 4, a second branch chain 5, a third branch chain 6, The fourth branch chain 7, the moving platform 8, the main shaft head 9 and the slide table 10. The bracket 1 is fixed on the ground, and the front beam 2 and the rear beam 3 are connected to the bracket through a rotating pair; connected, and the other ends are respectively connected to the moving platform 8 through a rotating pair; one end of the third branch chain 6 and the fourth branch chain 7 are respectively connected to the rear beam 2 through a rotating pair, and the other ends are respectively connected to the moving platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com