Preparation method of elastomer material for plastic runway

An elastomer material and plastic track technology, applied in the field of polymer materials, can solve the problems of high waste residue rate, easy disconnection, increase production cost of elastomer materials, etc., achieve low waste residue rate, prolong service life, and reduce preparation. The effect of the steps of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

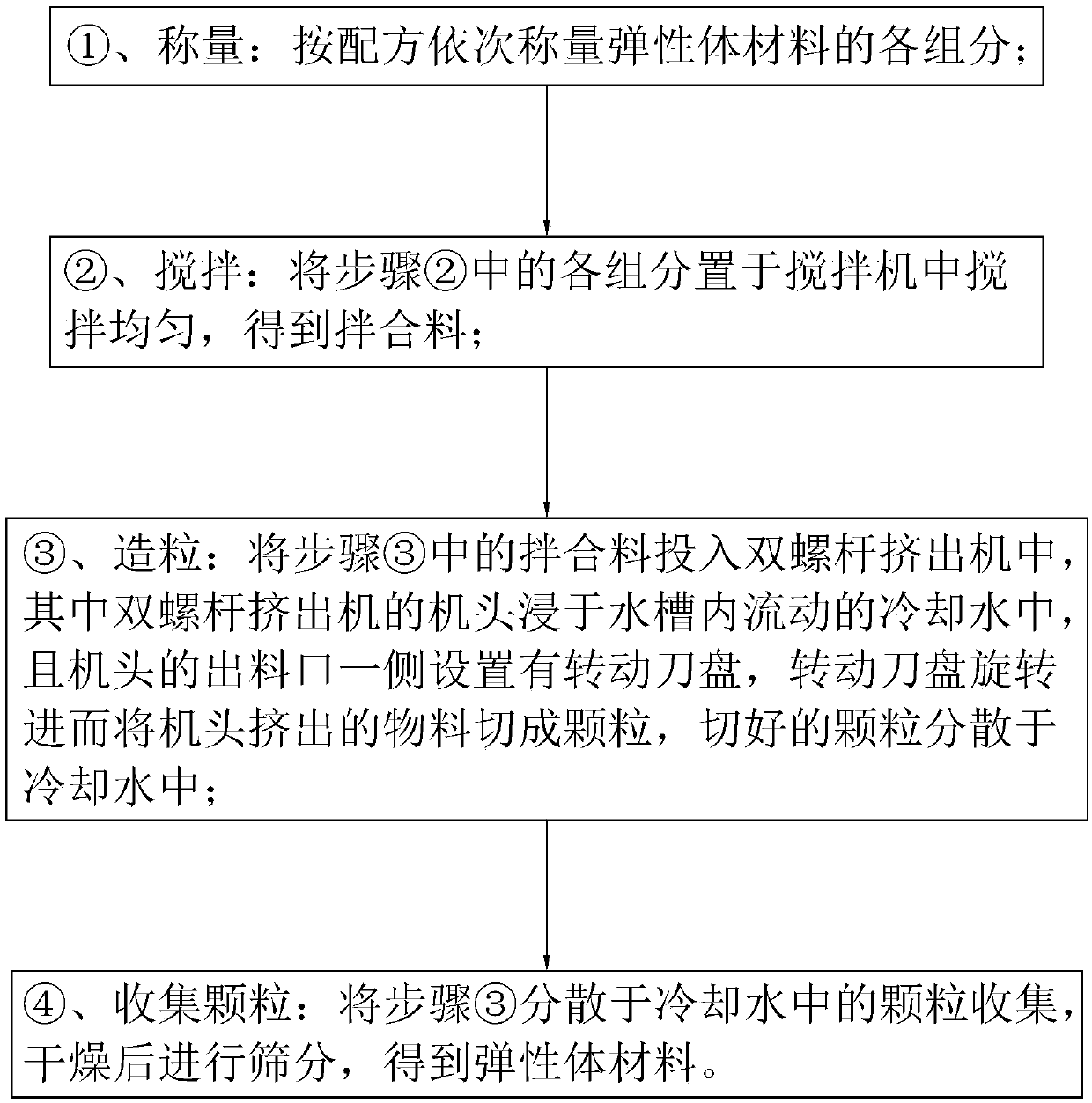

[0051] A kind of preparation method of the elastomeric material that is used for plastic runway, see figure 1 , including the following steps:

[0052] ① Weighing: Weigh the components of the elastomer material in turn according to the formula, the specific formula is 25kg EPDM, 5kg TPU, 35kg shell powder, 15kg naphthenic oil 4006, 5kg foaming agent, 0.5kg colorant, 0.1kg Antioxidant 1076, 0.2kg antiaging agent AW, 0.1kg odorless DCP and 0.1kg magnesium oxide.

[0053] ②. Stirring: put each component in step ① into a mixer, and stir evenly at 300-320r / min to obtain a mixture.

[0054] ③. Pelletizing: Put the mixture in step ② into the twin-screw extruder, control the working temperature of the twin-screw extruder to 200-220°C, and the screw speed to 40r / min, and extrude to granulate.

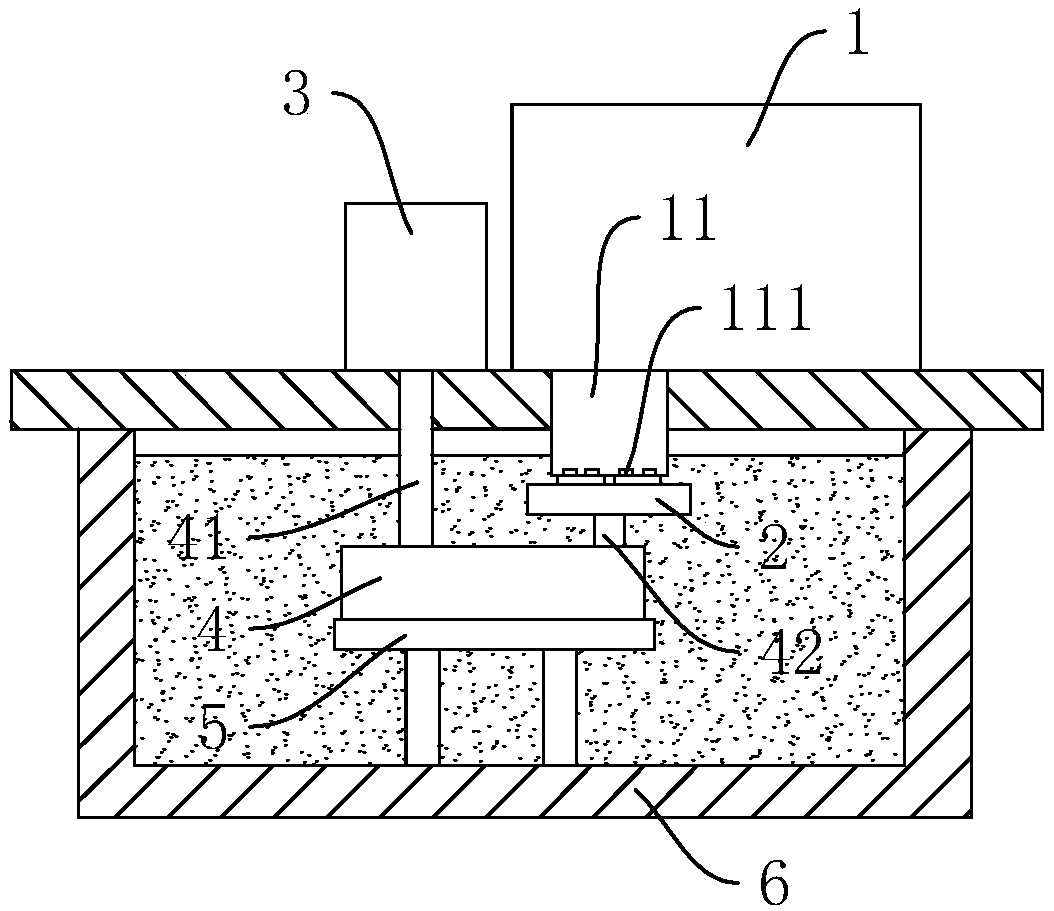

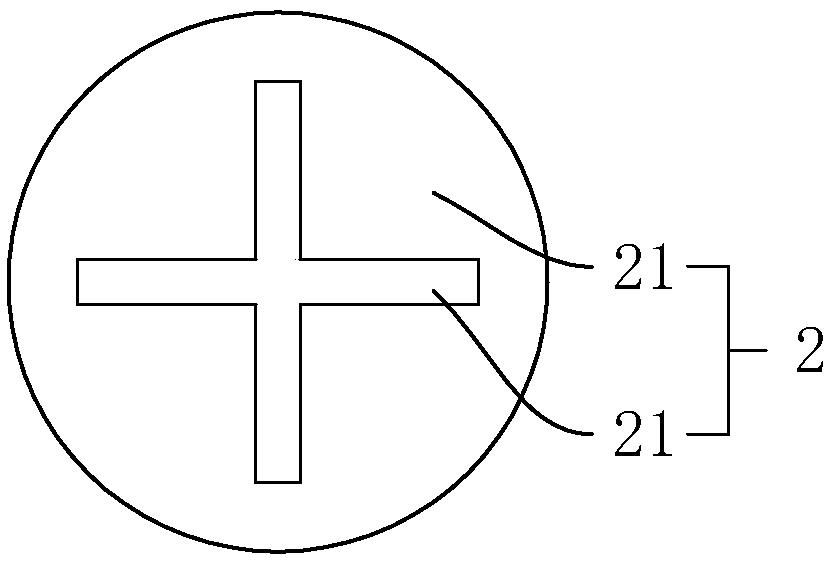

[0055] Wherein, the twin-screw extruder 1 that the present invention uses sees figure 2 , the machine head 11 is immersed in the cooling water flowing in the water tank 6, and the discharge ...

Embodiment 2-

[0057] 2.2, Example 2-Example 10

[0058] Embodiment 2-Embodiment 10 all adjusted each component and its quality on the basis of the method in Example 1. The adjustment, the components and the quality of the components in Example 1 are shown in the table below, and the unit is kg.

[0059]

[0060] 3. Comparative example

[0061] 3.1, comparative example 1

[0062] The difference from Example 1 is that this comparative example prepared the elastomeric material according to the conventional method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com