Pneumatic catapulting device and method of reusable working medium

A technology of working fluid and gas, applied in the field of projectile devices, can solve the problems of inability to realize application, increase the quality of projectile system, weak projectile ability, etc., achieve broad market prospects and application value, reduce economic and time costs, and extend service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

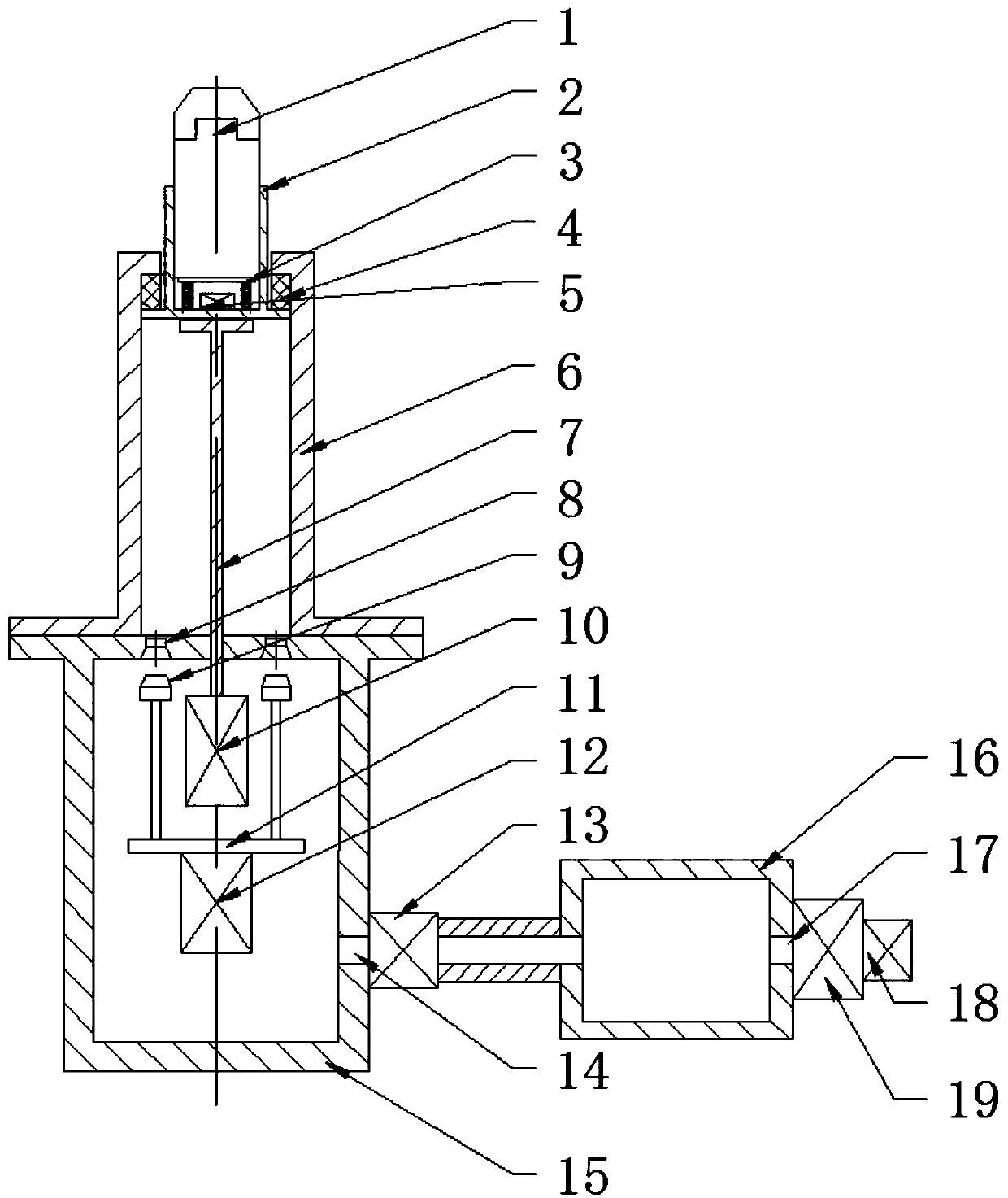

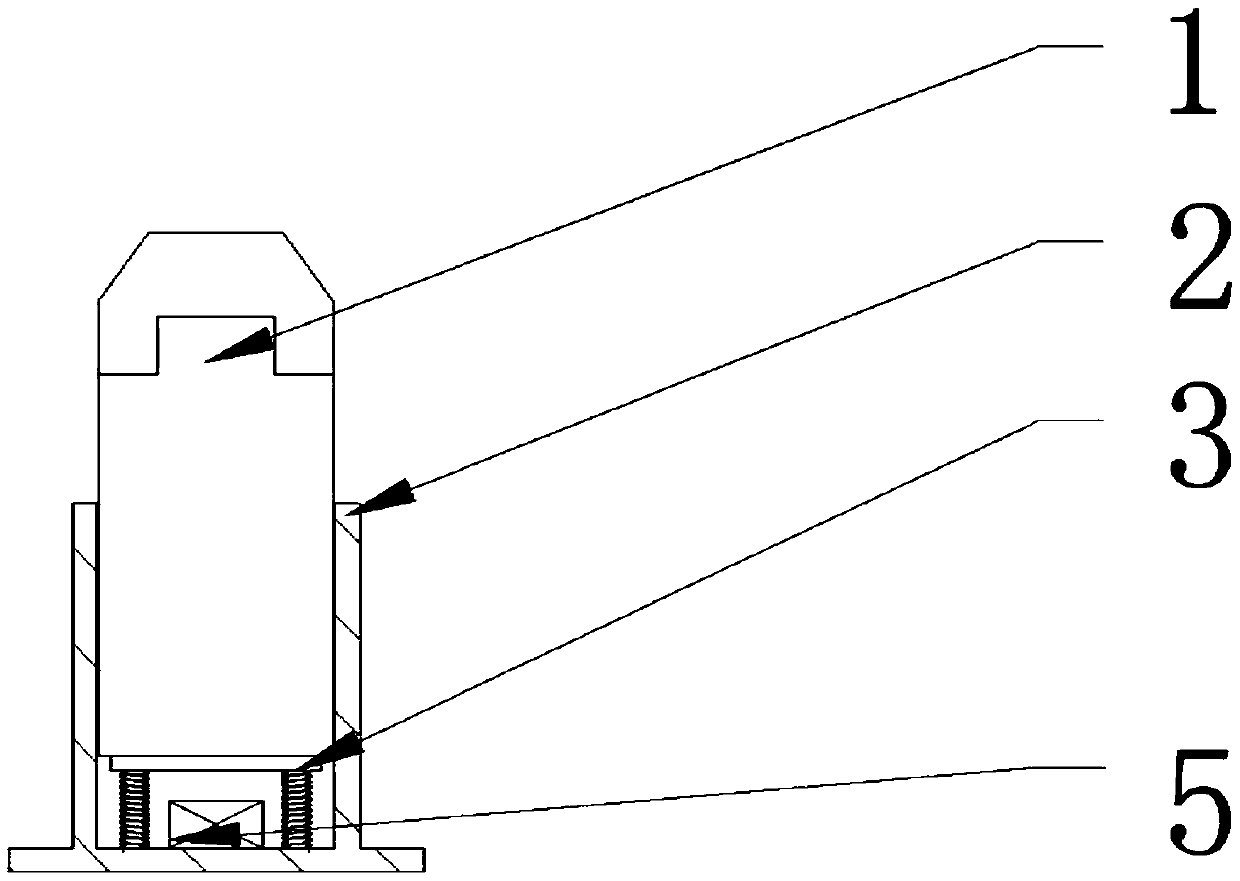

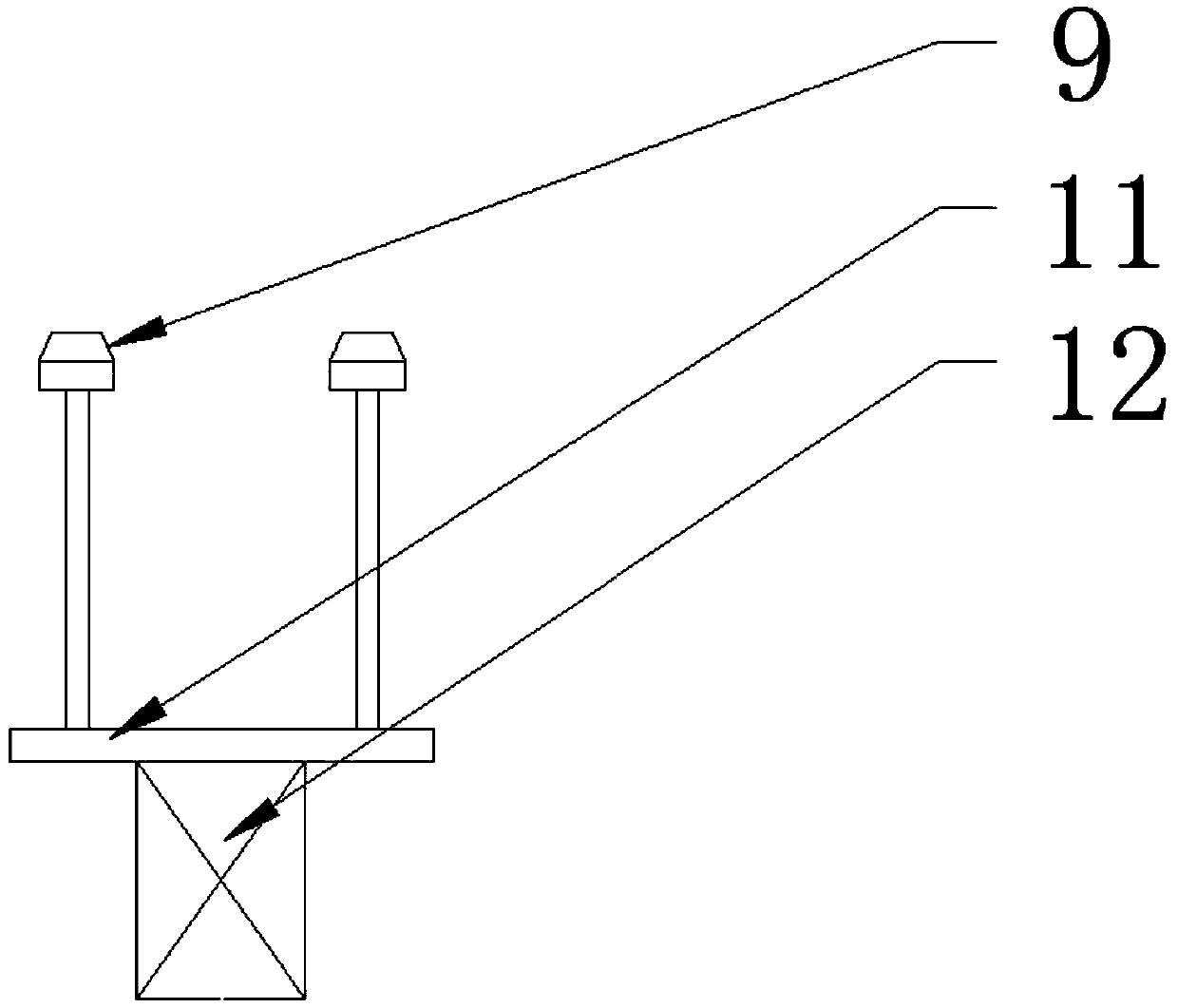

[0044] Such as Figure 1-5 As shown, a projecting device for reusable working fluid includes a carrier to be projected 1, a support cylinder 2, an electromagnetic booster 3, a buffer seal 4, a stroke sensor 5, a projecting cavity wall 6, a support cylinder rod 7, a guide Through hole 8, tie rod plug 9, servo motor a10, tie rod frame 11, servo motor b 12, compensation pressure sensor switch 13, pressure compensation hole 14, gas storage cavity wall 15, working medium compensation cavity wall 16, booster hole 17. Working medium gas generator 18, small supercharger 19; a part of the carrier 1 to be projected, the electromagnetic booster 3, and the travel sensor 5 are all placed inside the support tube 2, and the bottom of the carrier 1 to be projected and the electromagnetic booster The bottom of the electromagnetic booster 3 and the stroke ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com