Anti-shrinkage bonding mortar for foam glass-ceramic thermal insulation material

A technology of foamed glass-ceramic and thermal insulation material, which is applied in the field of building materials, can solve problems such as the inability to meet the bonding requirements of foamed glass-ceramics and walls, and can prevent sagging and water seepage, improve viscosity, and enhance water retention. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

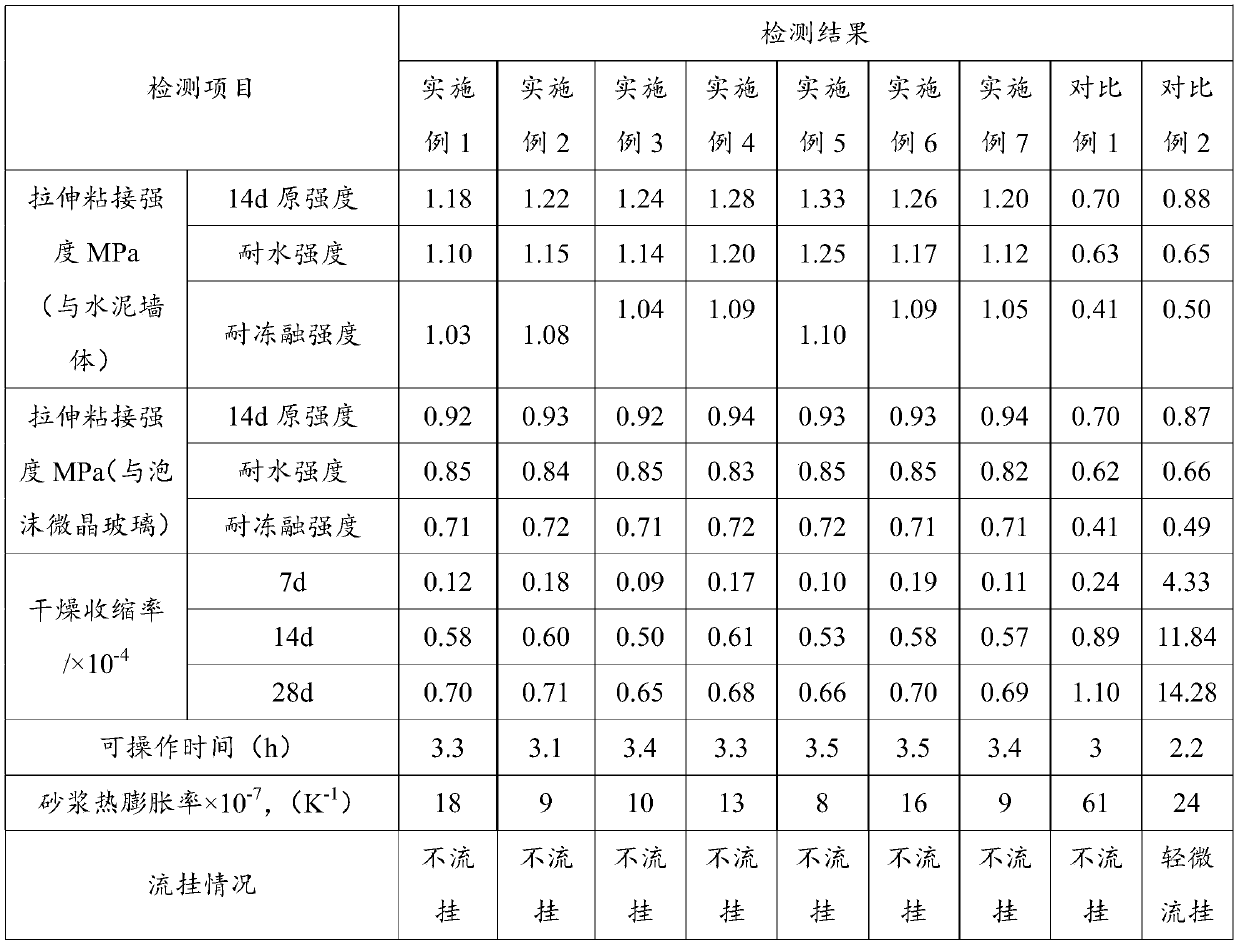

Examples

Embodiment 1

[0032] 20 parts of glass-ceramic particles, 20 parts of sand, 60 parts of cement, 0.5 parts of dispersible latex powder, 0.2 parts of wood fiber, 0.05 part of cellulose ether, 0.01 part of polypropylene fiber, 0.01 part of starch ether and 21 parts of water .

[0033] Mix the above materials, stir for 10 minutes until uniform without segregation, and let stand for 6 minutes.

Embodiment 2

[0035] 55 parts of glass-ceramic particles, 0 parts of sand, 45 parts of cement, 2.2 parts of dispersible latex powder, 0.6 parts of wood fiber, 0.3 part of cellulose ether, 0.2 part of polypropylene fiber, 0.2 part of starch ether and 21 parts of water .

[0036] Mix the above materials, stir for 10 minutes until uniform without segregation, and let stand for 6 minutes.

Embodiment 3

[0038] 50 parts of glass-ceramic particles, 25 parts of sand, 25 parts of cement, 2 parts of dispersible latex powder, 0.3 parts of wood fiber, 0.35 parts of cellulose ether, 0.1 part of polypropylene fiber, 0.04 part of starch ether and 21 parts of water .

[0039] Mix the above materials, stir for 10 minutes until uniform without segregation, and let stand for 6 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com