A heat treatment method for reducing the yield ratio of low-carbon bainite bridge steel

A technology of low-carbon bainite and heat treatment method, which is applied in the field of steel plate heat treatment, can solve the problems that the yield ratio of the steel plate is not given, reduces the rolled steel plate, damages the low-temperature fracture toughness, etc., and achieves short heat treatment cycle and low oxidation burning loss , the effect of reducing the yield ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The chemical composition of the steel plate includes: C 0.10%, Si 0.20%, Mn 1.48%, Cr 0.13%, Ni 0.13%, Nb 0.020%, Ti 0.015%, Alt 0.030%, P≤0.013%, S≤ 0.005%, the rest is Fe and unavoidable impurities.

[0031] 1) Prepare a cast slab with the same chemical composition as the above-mentioned steel plate, heat the cast slab at a heating temperature of 1180°C to 1200°C, and then perform TMCP rolling to obtain a steel plate with a thickness of 20mm;

[0032]2) Put the steel plate in a heat treatment furnace, raise the temperature to 760°C at a heating rate of 480°C / min, take it out of the furnace immediately after reaching the temperature, and air cool to room temperature.

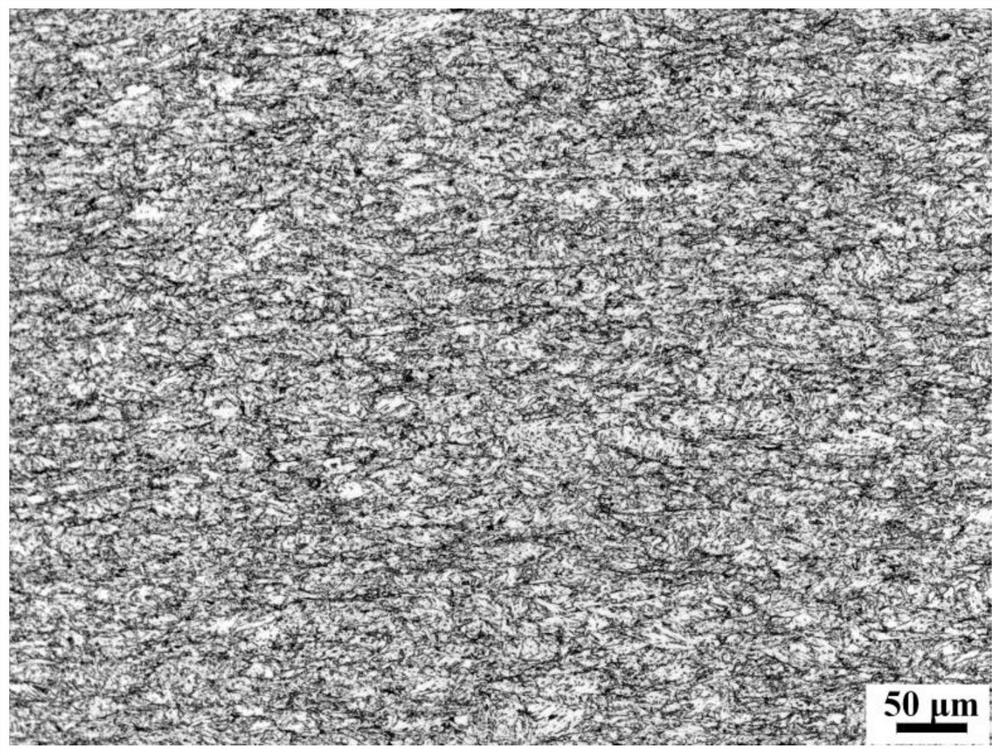

[0033] The photo of the microstructure at 500 times the longitudinal section of the steel plate at 1 / 4 is as follows: figure 1 As shown, the structure of the steel plate is a ferrite + bainite dual phase structure, wherein the volume fraction of ferrite is 33.5%, and the rest is bainite. The mechanical...

Embodiment 2

[0038] The chemical composition of the steel plate includes by weight percentage: C 0.05%, Si 0.25%, Mn 1.55%, Cr 0.20%, Ni 0.17%, Mo 0.12%, Cu 0.17%, Nb 0.030%, Ti 0.015%, Alt 0.029% , P≤0.012%, S≤0.005%, and the rest are Fe and unavoidable impurities.

[0039] 1) Prepare a cast slab with the same chemical composition as the above-mentioned steel plate, heat the cast slab at a heating temperature of 1180°C to 1200°C, and then perform TMCP rolling to obtain a steel plate with a thickness of 30mm;

[0040] 2) Put the steel plate in the heat treatment furnace, raise the temperature to 770°C at a heating rate of 415°C / min, take it out of the furnace immediately after reaching the temperature, and cool it to room temperature in air.

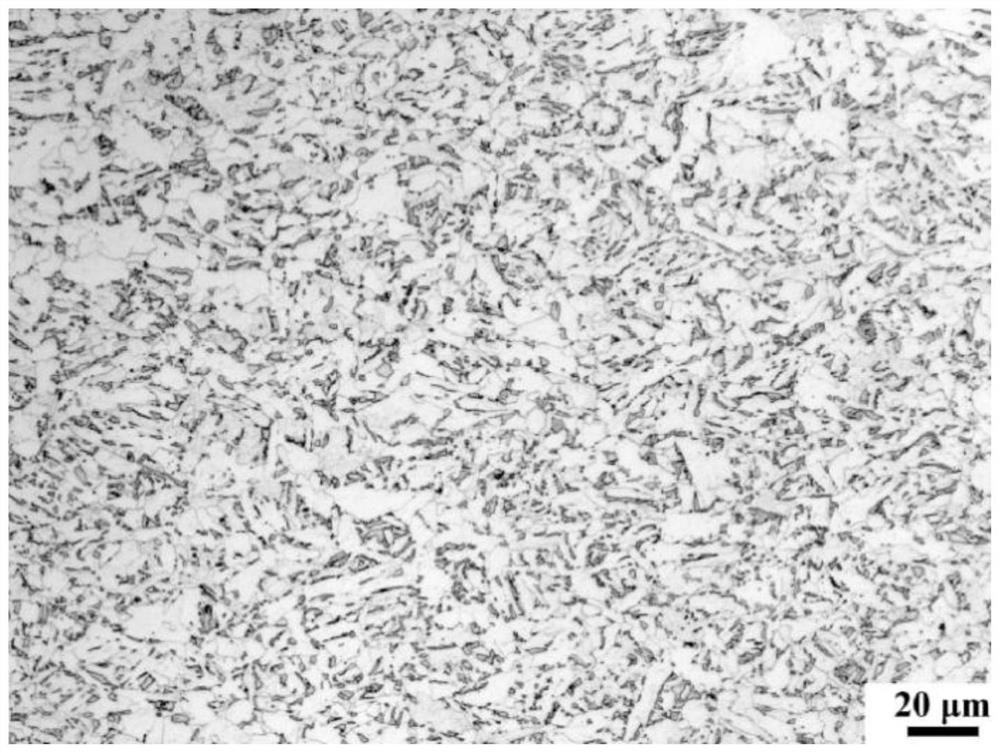

[0041] The photo of the microstructure at 500 times the longitudinal section of the steel plate at 1 / 4 is as follows: image 3 As shown, the structure of the steel plate is a ferrite + bainite dual phase structure, wherein the volume fraction of fer...

Embodiment 3

[0046] The chemical composition of the steel plate includes by weight percentage: C 0.05%, Si 0.15%, Mn 1.58%, Cr 0.30%, Ni 0.40%, Mo 0.15%, Cu 0.30%, Nb 0.045%, Ti 0.013%, Alt 0.020% , P≤0.010%, S≤0.003%, and the rest are Fe and unavoidable impurities.

[0047] 1) Prepare a cast slab with the same chemical composition as the above-mentioned steel plate, heat the cast slab at a heating temperature of 1180°C to 1200°C, and then perform TMCP rolling to obtain a steel plate with a thickness of 16mm;

[0048] 2) Put the steel plate in the heat treatment furnace, raise the temperature to 780°C at a heating rate of 520°C / min, take it out of the furnace immediately after reaching the temperature, and air cool to room temperature.

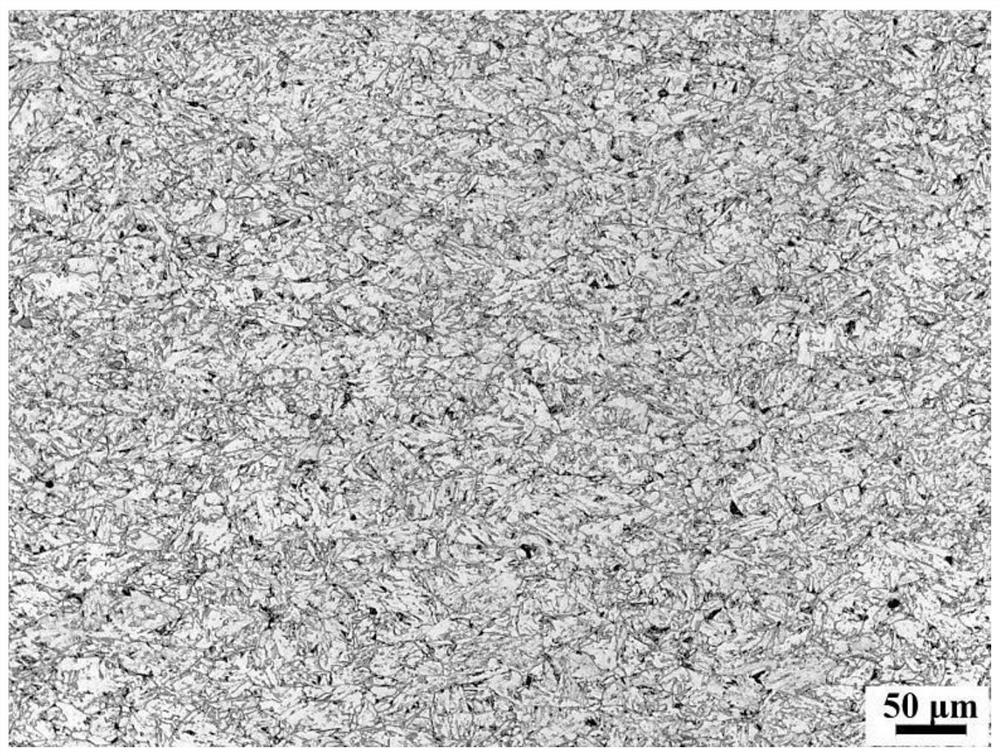

[0049] The photo of the microstructure at 500 times the longitudinal section of the steel plate at 1 / 4 is as follows: Figure 5 As shown, the structure of the steel plate is a ferrite + bainite dual phase structure, wherein the volume fraction of ferrite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com