Preparation method for cool anti-ultraviolet type bamboo fiber fabric

A bamboo fiber fabric, anti-ultraviolet technology, applied in the direction of fiber type, fiber treatment, plant fiber, etc., can solve the problems of poor coolness and smoothness, poor UV resistance, easy to pilling, etc., to achieve high environmental protection, low cost , the effect of enhancing cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

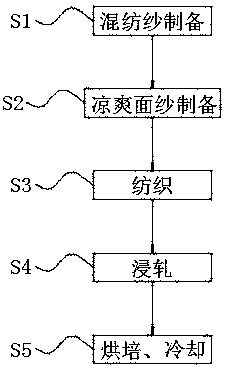

[0025] A kind of preparation method of cool anti-ultraviolet type bamboo fiber fabric, its preparation method is the following steps:

[0026] S1, preparation of blended yarn: blending wood fiber, bamboo fiber, spandex fiber, cotton fiber and soybean protein fiber to obtain blended yarn;

[0027] S2. Preparation of cool veil: blending silver fiber, silk fiber, cool fiber and environmental protection fiber to prepare a cool veil;

[0028] S3, weaving: adopt knitting machine to weave the blended yarn in S1 and the cool veil in S2 to form bamboo fiber fabric;

[0029] S4, padding: the bamboo fiber fabric prepared in S3 is then dipped and rolled in the anti-ultraviolet finishing solution, and the excess rate of one dipped and rolled is 50-80%;

[0030] S5. Baking and cooling: after the end of S4, bake again at a temperature of 130-180°C for 1-4 minutes, and finally cool to obtain the finished fabric.

[0031] Further, the blended yarn in S1 is made of components by weight: 5-15 ...

Embodiment 2

[0039] A kind of preparation method of cool anti-ultraviolet type bamboo fiber fabric, its preparation method is the following steps:

[0040] S1, preparation of blended yarn: blending wood fiber, bamboo fiber, spandex fiber, cotton fiber and soybean protein fiber to obtain blended yarn;

[0041] S2. Preparation of cool veil: blending silver fiber, silk fiber, cool fiber and environmental protection fiber to prepare a cool veil;

[0042] S3, weaving: adopt knitting machine to weave the blended yarn in S1 and the cool veil in S2 to form bamboo fiber fabric;

[0043] S4, padding: then the bamboo fiber fabric prepared in S3 is dipped and rolled in the anti-ultraviolet finishing liquid, and the excess rate of one dipped and rolled is 65%;

[0044] S5. Baking and cooling: after the end of S4, further baking is carried out at a temperature of 160° C. for 1.5 minutes, and finally the finished fabric is obtained after cooling.

[0045] Further, the blended yarn in S1 is prepared by ...

Embodiment 3

[0053] A kind of preparation method of cool anti-ultraviolet type bamboo fiber fabric, its preparation method is the following steps:

[0054] S1, preparation of blended yarn: blending wood fiber, bamboo fiber, spandex fiber, cotton fiber and soybean protein fiber to obtain blended yarn;

[0055] S2. Preparation of cool veil: blending silver fiber, silk fiber, cool fiber and environmental protection fiber to prepare a cool veil;

[0056] S3, weaving: adopt knitting machine to weave the blended yarn in S1 and the cool veil in S2 to form bamboo fiber fabric;

[0057] S4, padding: then the bamboo fiber fabric prepared in S3 is dipped and rolled in the anti-ultraviolet finishing liquid, and the excess rate of one dipped and rolled is 70%;

[0058] S5. Baking and cooling: after the end of S4, further baking is carried out at a temperature of 160° C. for 2 minutes, and finally the finished fabric is obtained after cooling.

[0059] Further, the blended yarn in S1 is prepared by pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com