Liquid external combustion engine

An external combustion engine technology, applied in the direction of rotary piston engine, machine/engine, rotary or swing piston engine, etc., can solve the problem of large size, achieve the effect of small device size, high thermal efficiency, and reduce system pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

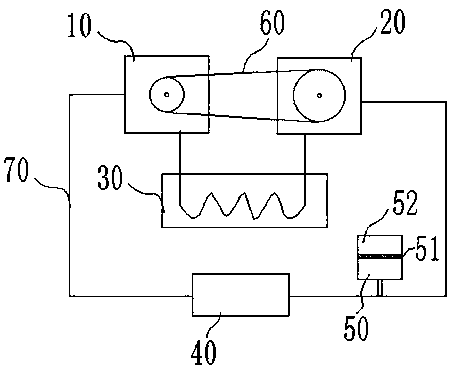

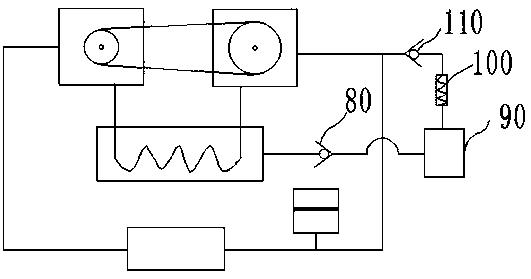

[0021] The embodiment of the present application provides a liquid external combustion engine, which mainly solves the problems of the current external combustion engine, such as insufficient thermal efficiency, large device volume so that its use is limited, and inability to effectively drive high-power workpieces. In the pump body, the heater heats the internal working medium. Due to the pressure difference between the two ends of the pump body and the different displacement of the two pump bodies, the working medium flows from the side with high pressure to the side with low pressure, thereby driving the output shaft to rotate. acting.

[0022] In order to better understand the above-mentioned technical solution, the technical solution of the present invention is described in detail below in conjunction with the accompanying drawings and specific embodiments:

[0023] Such as figure 1 As shown, the present application is a liquid external combustion engine, which mainly in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com