A Monitoring and Control System of Tunnel Model Test Platform Based on 3D Model

A three-dimensional model and test platform technology, applied in the field of servo control systems, can solve the problems of segment damage, low system work efficiency, and difficulty in system control implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

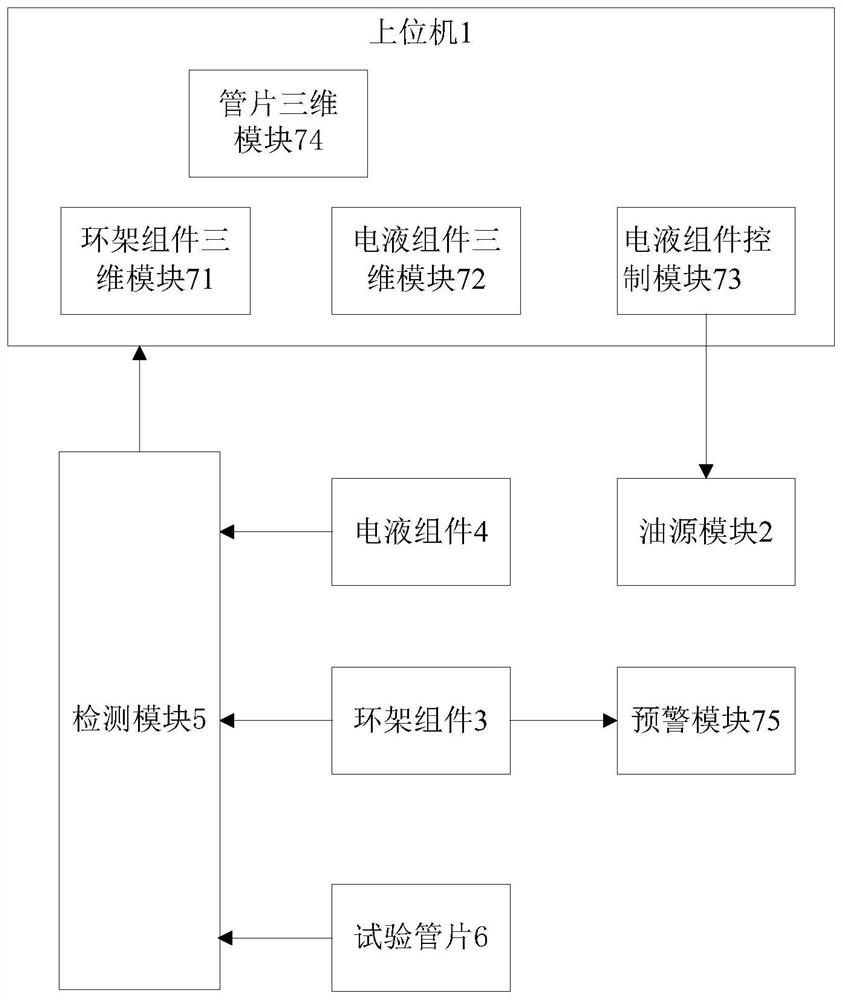

[0011] Embodiment 1: A monitoring and control system for a tunnel model test platform based on a three-dimensional model, including a host computer 1 storing a three-dimensional model control module, an oil source module 2, a ring frame assembly 3, an electro-hydraulic assembly 4, and a detection module 5, The oil source module 2 is used to provide the working fluid to the electro-hydraulic component 4, and the detection module 5 is used to respectively detect the working status information of the ring frame component 3, the working status information of the electro-hydraulic component 4 and the working status information of the test segment 6 and send the To the three-dimensional model control module, the three-dimensional model control module includes the ring frame assembly three-dimensional module 71, the electro-hydraulic assembly three-dimensional module 72, the electro-hydraulic assembly control module 73 and the segment three-dimensional module 74, and the ring frame ass...

Embodiment 2

[0012] Embodiment two: all the other parts are the same as in embodiment one, and the difference is that the three-dimensional model control module also includes an early warning module 75, and the early warning module 75 stores the ring frame assembly 3 working state threshold and the segment working state threshold, and the early warning module 75 uses To receive the working state information of the ring frame assembly 3 and the working state information of the test segment, and combine the working state information of the ring frame assembly 3 and the working state information of the test segment with the working state threshold of the ring frame assembly and the working state threshold of the segment Corresponding comparisons are made, and then a qualified or unqualified judgment result is obtained according to preset rules. When the comparison result is unqualified, the early warning module 75 sends corresponding early warning information.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com