A terahertz wave photonic crystal device with real-time adjustable response frequency band and its preparation method and application

A photonic crystal and terahertz wave technology, applied in the field of terahertz wave applications, can solve problems such as unfavorable technical barriers, elimination, and single working frequency band

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The process of preparing a terahertz photonic crystal device in this embodiment is as follows:

[0025] Step 1: Add 5g of iron powder into 5g of Dow Corning SE1700, and mix evenly to obtain the magnetic ink to be printed.

[0026] Step 2, the ink is loaded into the printer barrel, the pitch of the close-packed structure is set to 500 microns, and the layer height is 150 microns, and the photonic crystal structure is printed according to the three-dimensional wood stack structure array.

[0027] In step 3, the printed photonic crystal three-dimensional array is heated and cured at 100° C. for 1 hour.

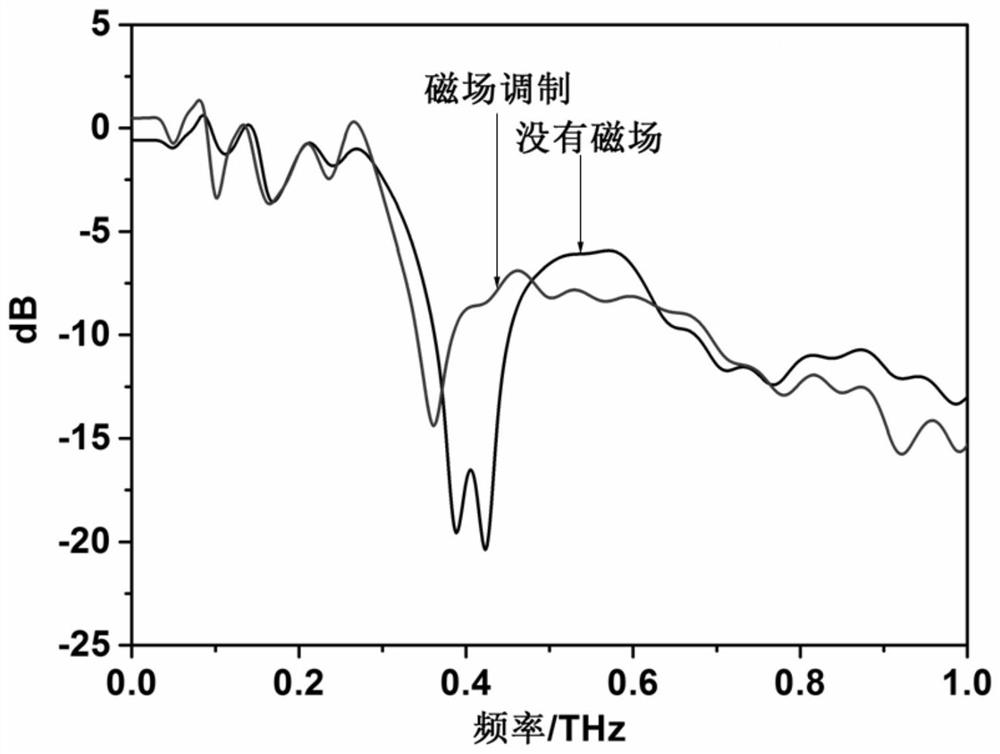

[0028] Step 4, conduct a terahertz spectrum test on the heat-treated terahertz photonic crystal stealth device, and obtain the photonic band gap through Fourier transform, and the result is in figure 1 displayed in (no magnetic field).

[0029] Step 5: Modulate the terahertz photonic crystal cloaking device with an external magnetic field, and at the same time perform te...

Embodiment 2

[0031] The process of preparing a terahertz photonic crystal device in this embodiment is as follows:

[0032] Step 1: Add 5g of iron powder into 5g of Dow Corning SE1700, and mix evenly to obtain the magnetic ink to be printed.

[0033] Step 2, the ink is loaded into the printer barrel, the pitch of the close-packed structure is set to 400 microns, and the layer height is 150 microns, and the photonic crystal structure is printed according to the three-dimensional wood stack structure array.

[0034] In step 3, the printed photonic crystal three-dimensional array is heated and cured at 100° C. for 2 hours.

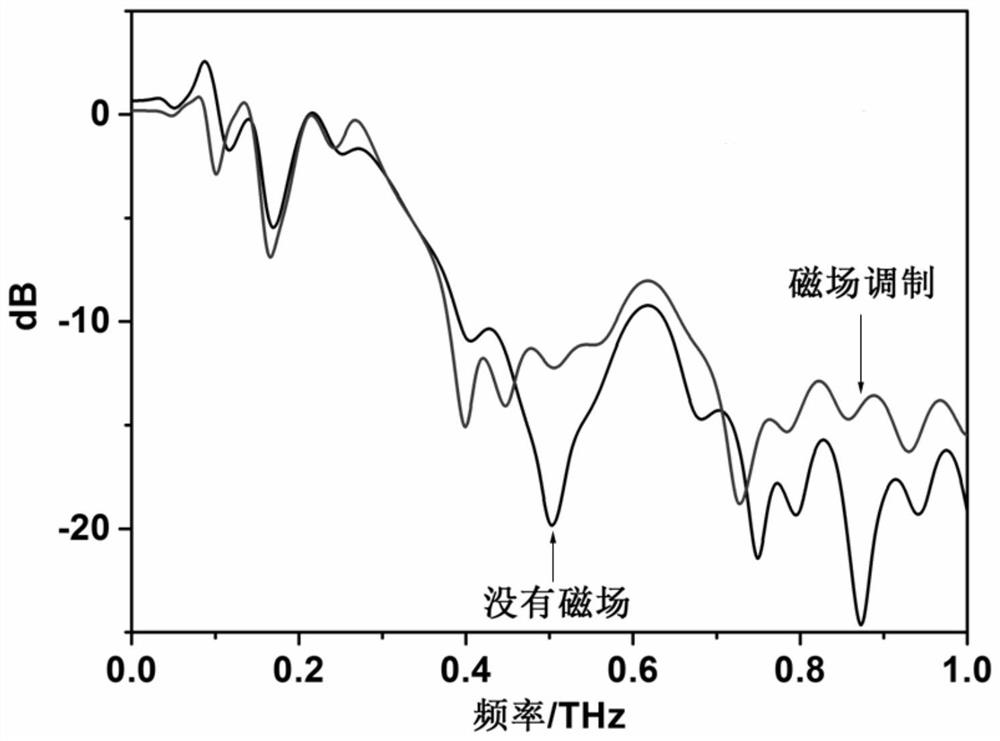

[0035] Step 4, conduct a terahertz spectrum test on the heat-treated terahertz photonic crystal stealth device, and obtain the photonic band gap through Fourier transform, and the result is in figure 2 displayed in (no magnetic field).

[0036] Step 5: Add magnetic field modulation to the terahertz photonic crystal stealth device, and perform terahertz time-domain spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com