Movable multi-purpose power distribution training platform

A training platform and multi-functional technology, applied in instruments, simulators, space navigation equipment, etc., can solve problems such as training and drills, and achieve the effects of improving safety, avoiding high-altitude falling accidents, and being convenient and flexible to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

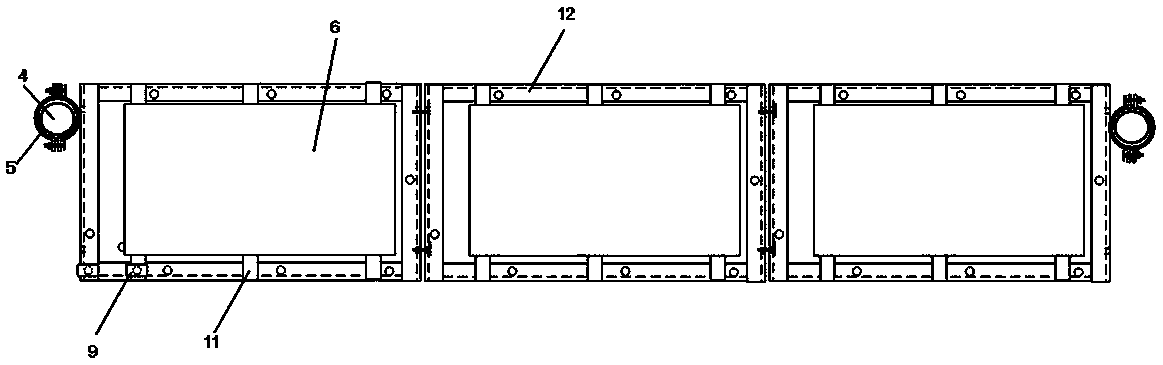

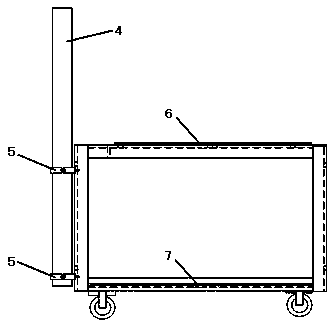

[0025] Such as image 3 As shown, the split platform 1 is welded by 4 pieces of 1m long ∠63×6 galvanized angle steel 12 and 8 pieces of 0.8m long ∠63×6 galvanized angle steel 12 and 4 pieces of -50×5 galvanized flat plates. The welding part is painted with anti-corrosion paint, and an 8mm thick bakelite insulating platen 6 is laid on the top of the split platform 1, and a 10mm thick wooden platen 7 is laid on the bottom; two galvanized flat plates are installed horizontally inside to separate the interior of the split platform 1. It is divided into three layers for easy storage. Four 360-degree rotating rubber wheels 3 with a diameter of 80mm are installed at the bottom for easy movement; a 2m long φ160 galvanized steel pipe 4 and a steel pipe fixing hoop 5 are installed in the split body One side of platform 1, simulates an electric pole. The split platform 1 can be used to perform training operations such as wire fixing and binding on pin insulators and butterfly insulators, ...

Embodiment 2

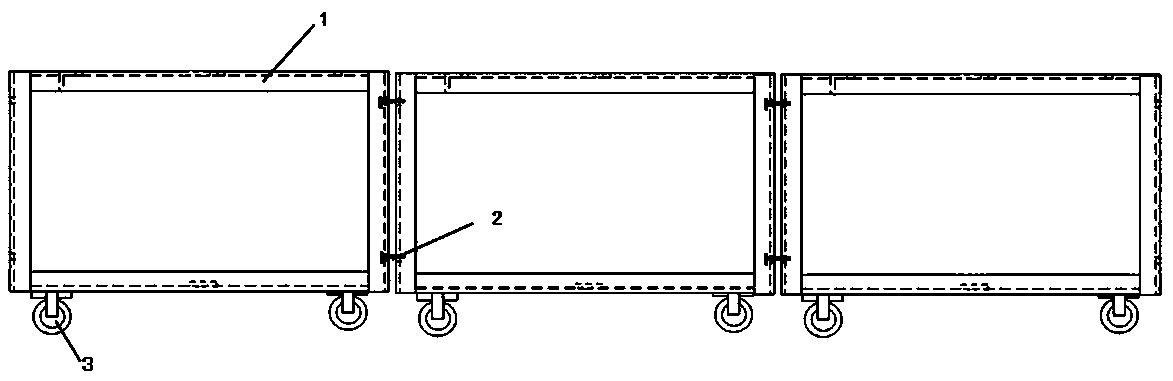

[0027] Such as figure 1 , image 3 As shown, three split platforms 1 are formed by connecting bolts 2 to form a training platform, and galvanized steel pipes 4 are installed on both sides through steel pipe fixing hoops 5 to simulate telephone poles, and the following power distribution practical projects can be completed:

[0028] ① The wires are fixed and tied on pin insulators and butterfly insulators;

[0029] ②Pull line, middle and bottom handle production;

[0030] ③Cable head production;

[0031] ④ Cross arm installation; wire erection;

[0032] ⑤ Installation of drop switch;

[0033] ⑦Pull wire installation;

[0034] ⑧ Installation of grounding clamp, bird repellent and line fault indicator

[0035] ⑨Training projects such as installing the household connection line on the electric pole.

[0036] The training platform is usually disassembled and placed in a warehouse or other rain and dust-proof place when there is no training operation. When used, it can be separated or combined ac...

Embodiment 3

[0038] Such as Figure 4 As shown, the iron wire winding tool is a 10mm thick, 300mm long, 50mm wide bakelite insulation board, which is suitable for processing an oblique groove with a width of 5mm at a suitable position at one end for the use of galvanized iron wire to wind the steel stranded wire. The other end is drilled with a φ10 round hole, which is convenient for tools to be placed on the side of the platform, and usually placed in the storage layer inside the split platform 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com