Power transmission cable

A power transmission and cable technology, which is applied in the field of power transmission cables and cables for power transmission, can solve the problems of easy rolling of circular structures, low efficiency, cable fixing and inconvenient layout, etc., and achieves easy connection, wide application range, Effect of improving laying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

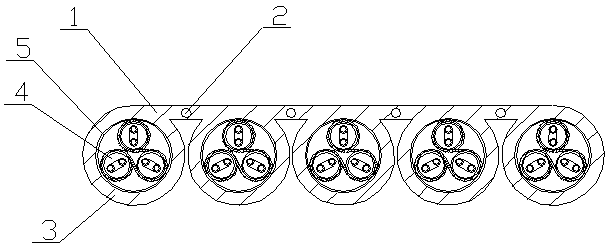

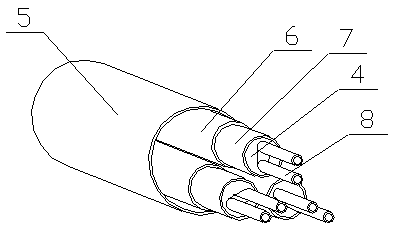

[0026] A power transmission cable of the present invention is realized in the following way: a power transmission cable of the present invention consists of a fixed base plate (1), load-bearing steel wire (2), outer protective sheath (3), wire (4), and non-woven fabric (5) , aluminum foil (6), wire insulation layer (7) and wire core (8), a plurality of outer protective sleeves (3) are equidistantly placed on the fixed substrate (1), and the outermost two outer protective sleeves (3 ) are respectively located at both ends of the fixed base plate (1), and Velcro fasteners are placed on the outer walls of the outermost two outer protective sleeves (3) and cooperate with each other. The cross-section of the outer protective sleeves (3) is circular, corresponding to There is a gap between two adjacent outer protective sleeves (3), the fixed base plate (1) is a rubber plate, and a plurality of load-bearing steel wires (2) are embedded in the fixed base plate (1), and they are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com