Negative pole active substance, method for producing same, and nonaqueous secondary battery

A technology of negative electrode active material and manufacturing method, which is applied in the direction of active material electrode, secondary battery, electrode manufacturing, etc., can solve the problems of low conductivity and low conductivity of negative electrode active material, and achieve high load characteristics and high long-term reliability. , the effect of excellent discharge rate characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

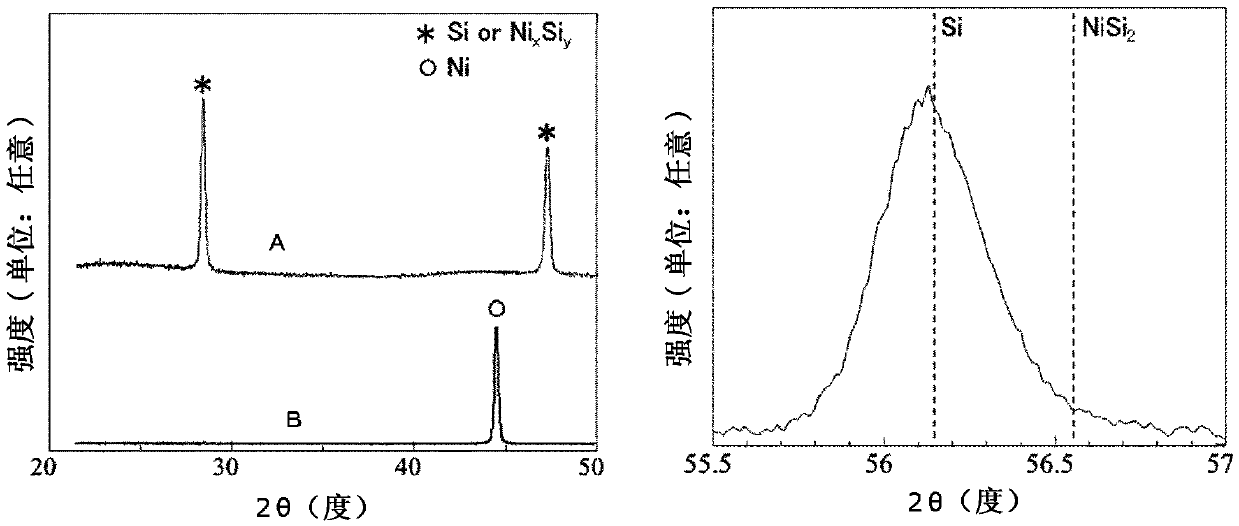

[0034] 2. Example 1 (negative electrode active material of the present invention, method for producing the same, and non-aqueous secondary battery)

Embodiment 2

[0035] 3. Example 2 (Application example of the non-aqueous secondary battery of Example 1)

[0036] 4. Other

[0037]

[0038] In the method for producing a negative electrode active material of the present invention, the nickel-containing solution preferably contains a nickel acetate salt. However, it is not limited to such a form, and any nickel-containing material (eg, nickel carbonate, nickel nitrate, nickel sulfate, etc.) can be used as long as it is a material capable of preparing a solution.

[0039] In the production method of the negative electrode active material of the present invention including the preferred aspect, the heat treatment may be performed at 600° C. to 1,000° C. for 1 hour or longer. In addition, in the production method of the negative electrode active material of the present invention including these preferred aspects, the reducing atmosphere is preferably an inert gas atmosphere containing hydrogen, but it is not limited to this, and an inert g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com