Heavy die preheating furnace bottom for multidirectional double-acting extrusion hydraulic press and die loading and unloading method

A technology for extruding hydraulic presses and preheating furnaces, applied in forging/pressing/hammering machinery, forging/pressing/hammer devices, furnaces, etc. The replacement method is outdated and cannot meet the productivity requirements, etc., to achieve remarkable novelty, short loading and unloading time, and good sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further clarified below in conjunction with the drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and not to limit the scope of the present invention.

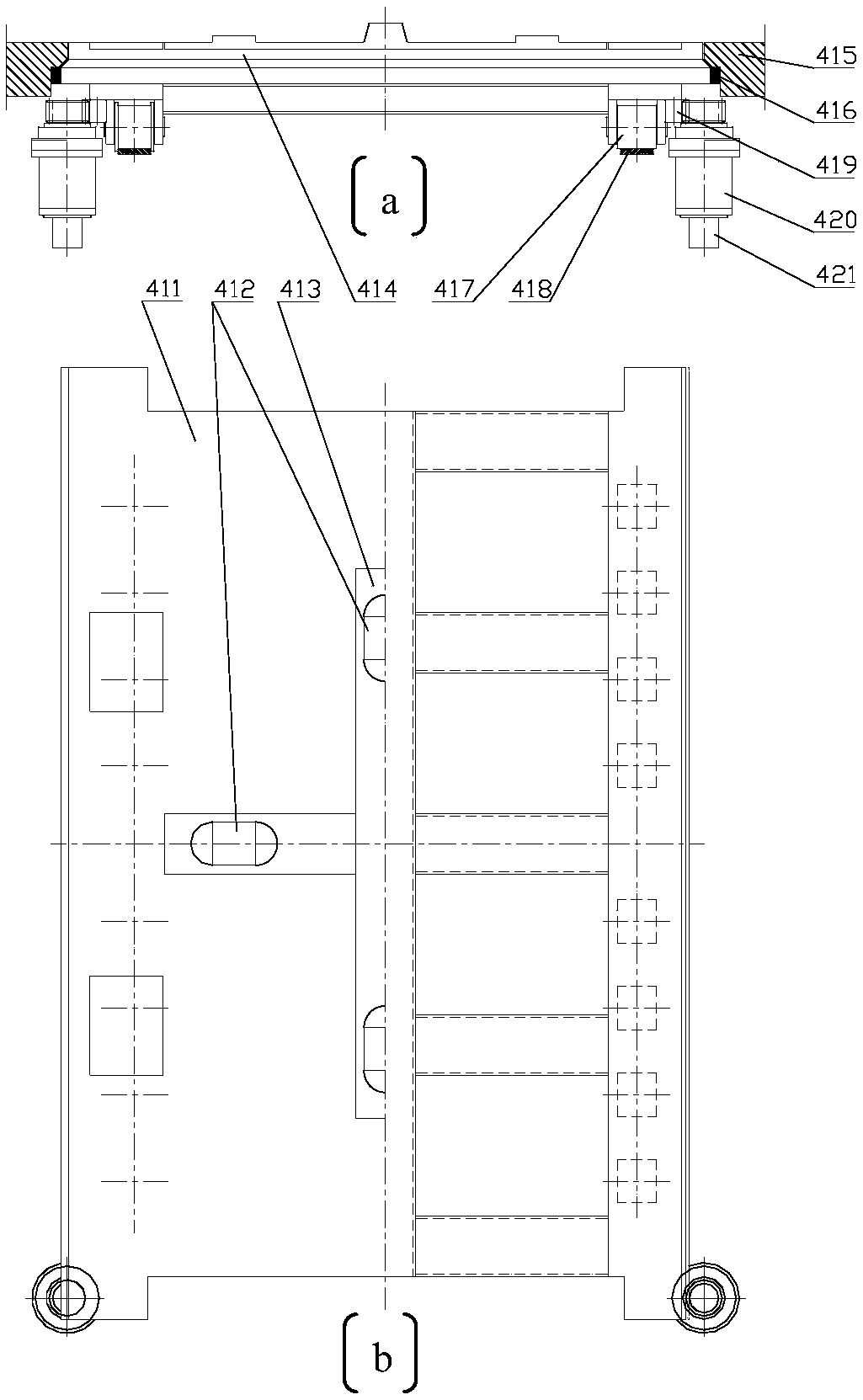

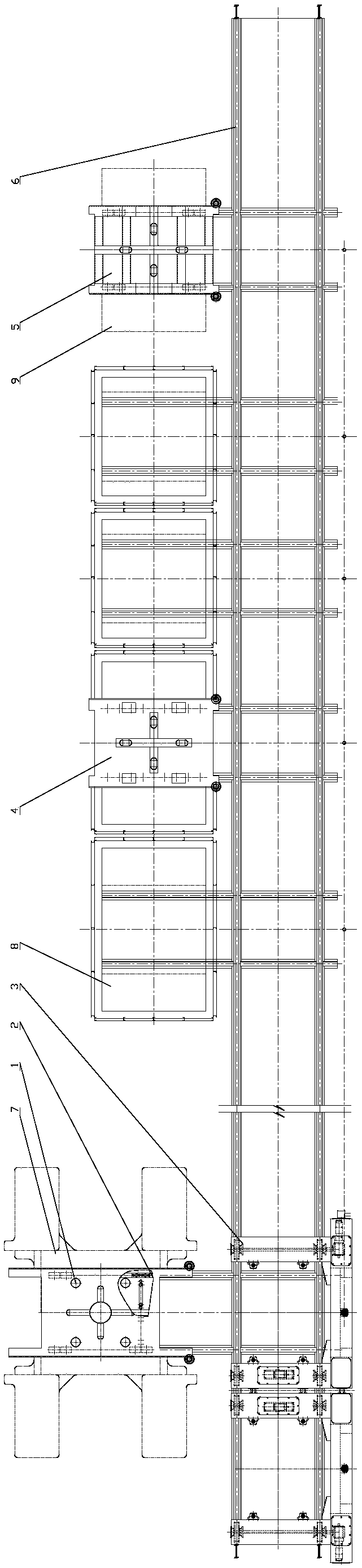

[0032] Combine figure 1 It can be seen that the furnace bottom 411 of the mold preheating furnace bottom device is a rigid welded frame movable structure, provided with mold longitudinal and transverse positioning keys 412 and backing beams 413. The positioning key and the keyway of the mold backing plate enable the mold to be positioned On the bottom of the furnace; a certain thickness of refractory fiber block 414 is laid on the upper part of the bottom of the furnace; a mechanical labyrinth type and ceramic glue bonding fiber band seal 416 is used between the bottom of the furnace 411 and the furnace body 415. The maximum carrying capacity is 120t.

[0033] The bottom chassis of the furnace is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com