End effector of taking and placing mechanical arm for heat-forming box type furnace

A technology of end picker and box furnace, which is applied in the field of picking and unloading manipulators, can solve the problems of easy to produce defective products, large distance between sheet material and heating resistance wire, and influence of hot stamping forming, so as to facilitate product forming and speed up The effect of easy control of transmission speed and temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

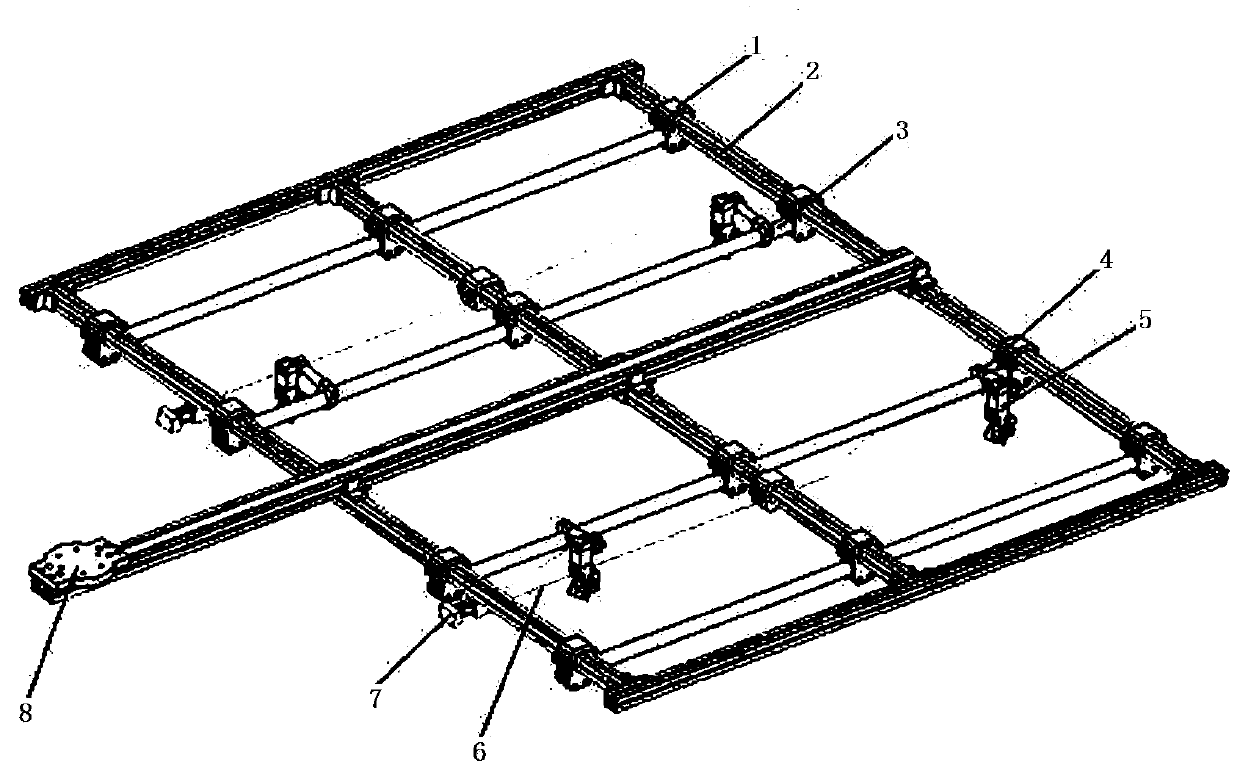

[0019] refer to figure 1 , the end picker of the present invention includes: a rectangular end picker frame 2 connected by square steel pipes, a cylindrical parallel rod 3 assembled in the frame, a sheet clamping assembly 5 assembled on the parallel rod 3, a The clamping assembly on the top acts as the cylinder 7, the transmission stay wire 6 between the cylinder 7 and the tablet clamping assembly 5. Parallel bar 3 is installed on the frame 2 in parallel with the fixed clip 1 tightened by screws. The sheet clamping assembly 5 is installed on the parallel bar 3 with the fixed clip 4 tightened by screws. The distance between the clamping components of two blanks on the same rod can adjust the fixed position according to the size of the blanks.

[0020] Among them, at least four clamping components 5 are arranged, and two by two are installed on two parallel rods 3 .

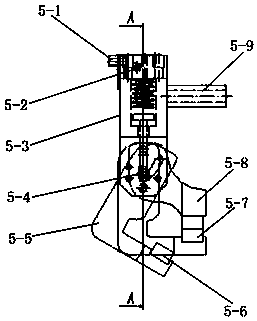

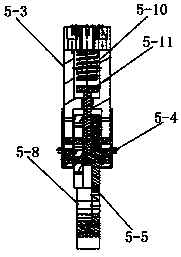

[0021] refer to figure 2 , image 3 , Figure 4 , Figure 5 , the sheet clamping assembly includes: a sq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com