Travelling motor heat dissipating system

A technology of walking motor and heat dissipation system, which is applied in the combination of power unit cooling layout, power unit, transportation and packaging, etc., which can solve the problems of reduced motor life, reduced motor output, and poor cooling effect of the motor to achieve heat dissipation Improved performance, saving parts and space, and improved heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

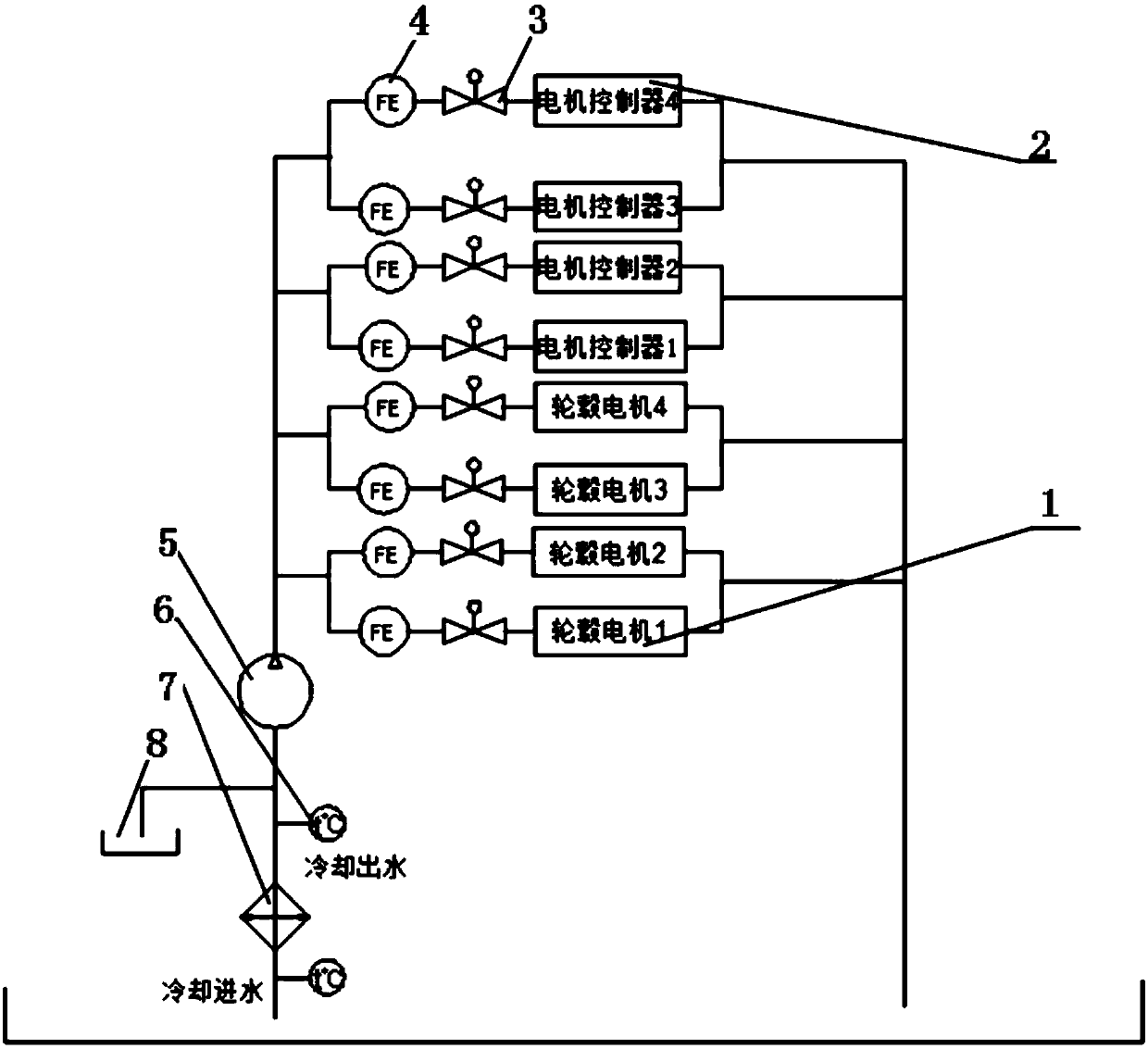

[0024] A walking motor heat dissipation system, the system adopts four sets of motors and four sets of motor controllers connected in parallel, under the premise of the same motor, motor controller, water pump, radiator, etc., the heat dissipation capacity of the motor should be significantly improved, and at the same time A flow meter and an electric ball valve are installed on each parallel waterway to adjust the flow in each branch in real time, so that the heat dissipation effect of the walking motor is significantly improved.

[0025] Use one water pump to provide coolant for four motors and motor controllers at the same time, which saves the number of structural parts. Four motors and four motor controllers are connected in parallel, so that the walking motor, motor controller, water pump, radiator, etc. are the same Under the premise, the heat dissipation capacity of the motor is significantly improved. Electric ball valves and flow meters are connected to the pipeline b...

Embodiment 2

[0046] A heat dissipation method for a traveling motor, characterized in that it comprises:

[0047] Obtain the temperature signal of the water outlet of the radiator, and control the speed of the fan of the radiator based on the temperature signal of the water outlet of the radiator; When the temperature is higher than a certain set temperature, the fan is turned on at full speed, and the speed regulation method of the fan is linear smooth speed change, stepless speed change;

[0048] Obtain the flow signal in each branch, and when the flow value in the branch is greater than the preset value, send a signal to the electric ball valve in the branch, and the electric ball valve will reduce the opening size according to the flow signal provided by the flowmeter. Similarly, When the flowmeter detects that the flow in the branch is less than the preset value, it sends a signal to the electric ball valve in the branch, and the electric ball valve increases the opening size accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com